A dual laser robot joint angle measurement method and angle measurement device

An angle measuring device and a technology of robot joints, which are applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to guarantee the attitude measurement of robot joints, inability to adapt to production application scenarios, and insufficient dynamic range, so as to reduce errors , Inexpensive, Reliable Measuring Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

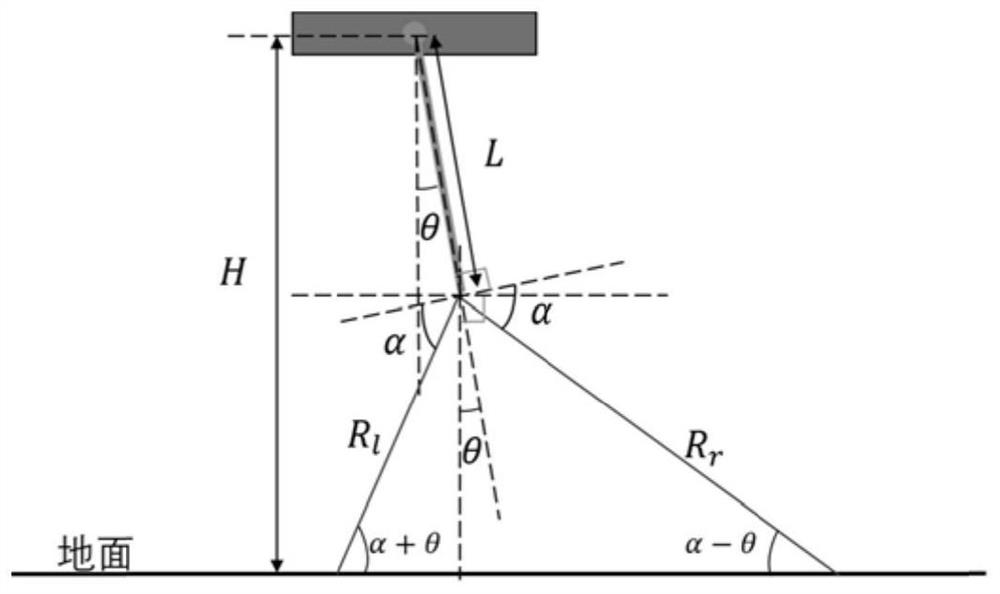

[0054]This embodiment provides a method for measuring the joint angle of a dual laser robot. The method uses the ground plane as a reference plane to construct a laser-plane angle measurement model, and converts the rotation angle of the joint by converting the geometric relationship between the laser distance measurement and the rotation angle of the joint. The angle change is converted into the laser ranging change. During real-time measurement, the rotation angle of the robot joint is obtained by measuring the dual laser ranging change value at the robot joint and the laser-plane angle measuring model. The method includes the following steps:

[0055] 1) A dual laser range finder is installed on the robot. The dual laser range finder includes two dual lasers, and the angle between the outgoing laser of the laser and the vertical direction of the arm axis is set according to the measurement requirements;

[0056] 2) Real-time acquisition of the left and right laser ranging v...

Embodiment 2

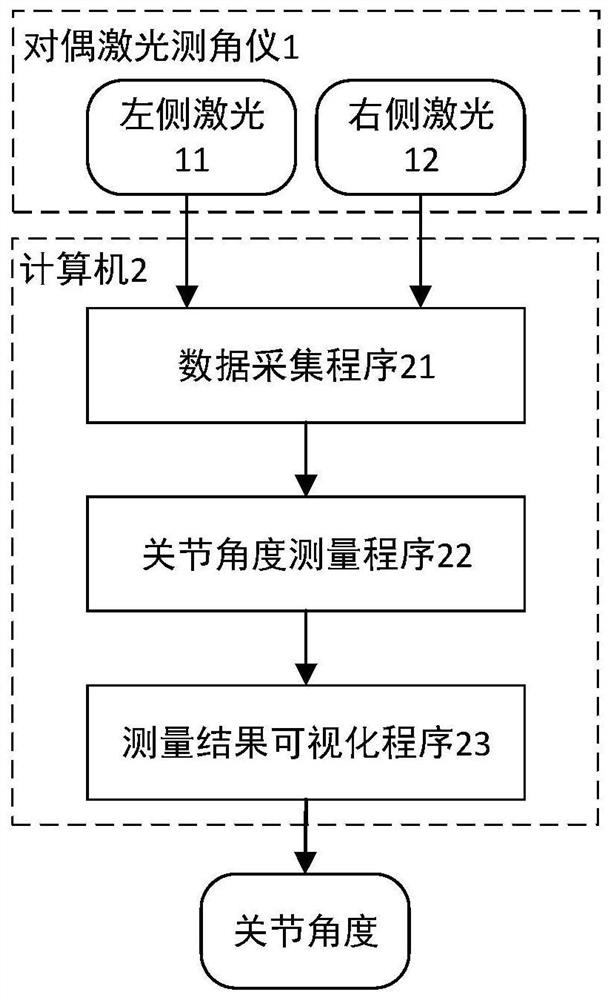

[0087] like figure 1 As shown, this embodiment provides a dual laser type robot joint angle measurement device, including a dual laser range finder 1 and a computer 2, wherein the dual laser range finder 1 is installed on the robot, and its central axis is the same as the arm axis of the robot. Parallel; the computer 2 is connected to the dual laser rangefinder, collects the left and right laser distance measurement values of the dual laser rangefinder in real time during the movement of the robot joint, and obtains the rotation angle of the robot joint based on the laser-plane angle measurement model. The measurement principle of the angle measurement device is as in Embodiment 1.

[0088] The dual laser rangefinder 1 can be installed in the axial direction of the robot arm, such as at the end of the robot or on the side of the robot arm, as long as it is parallel to the movement direction.

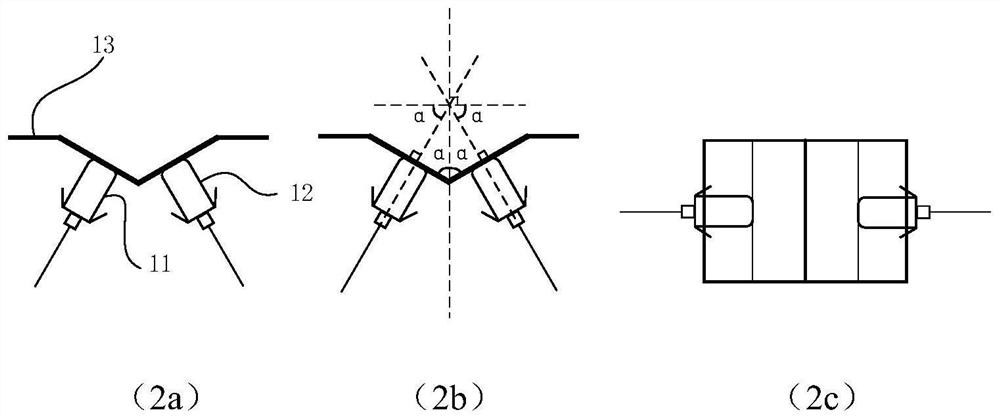

[0089] like figure 2 As shown, the dual laser rangefinder includes a V-shaped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com