Solar condensing lens and production method thereof

A technology of solar concentrating and production methods, which is applied in the field of concentrating lenses, can solve the problems of concentrating lens damage, concentrating lens damage, and concentrating lenses that cannot reflect sunlight, etc., and achieve the effect of improving structural strength and ensuring reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

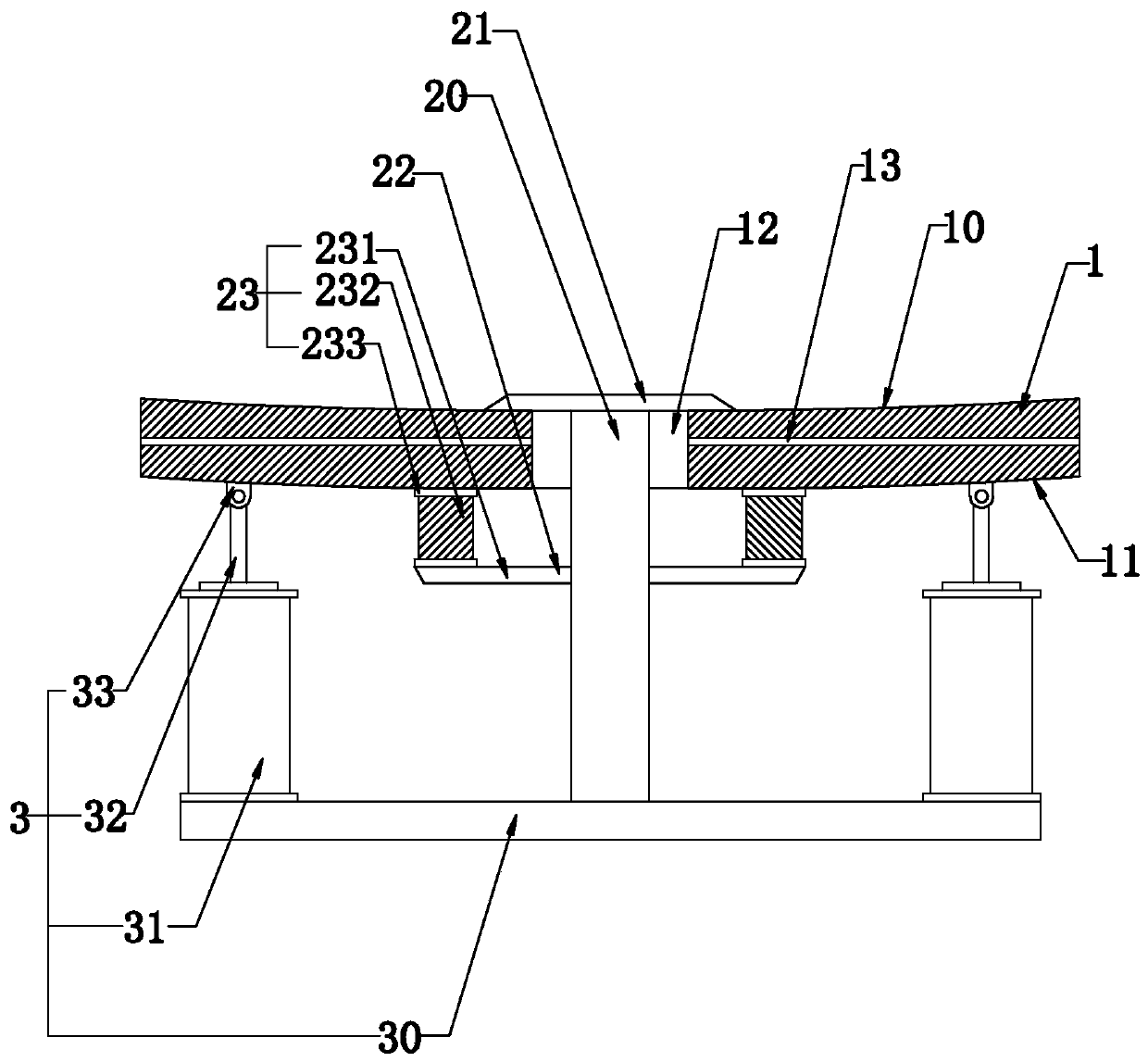

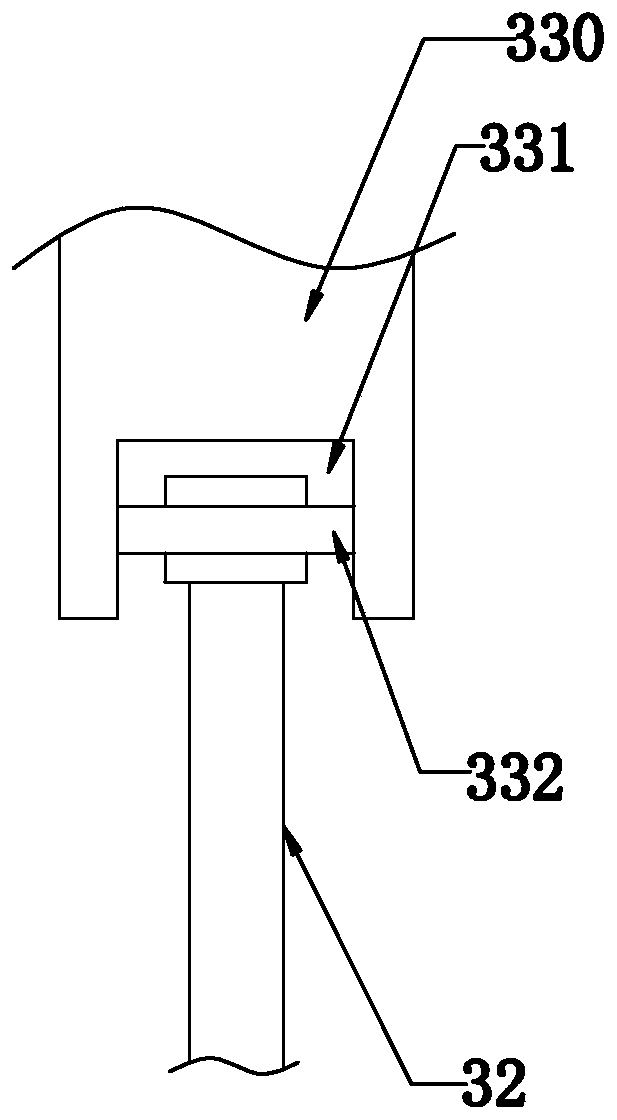

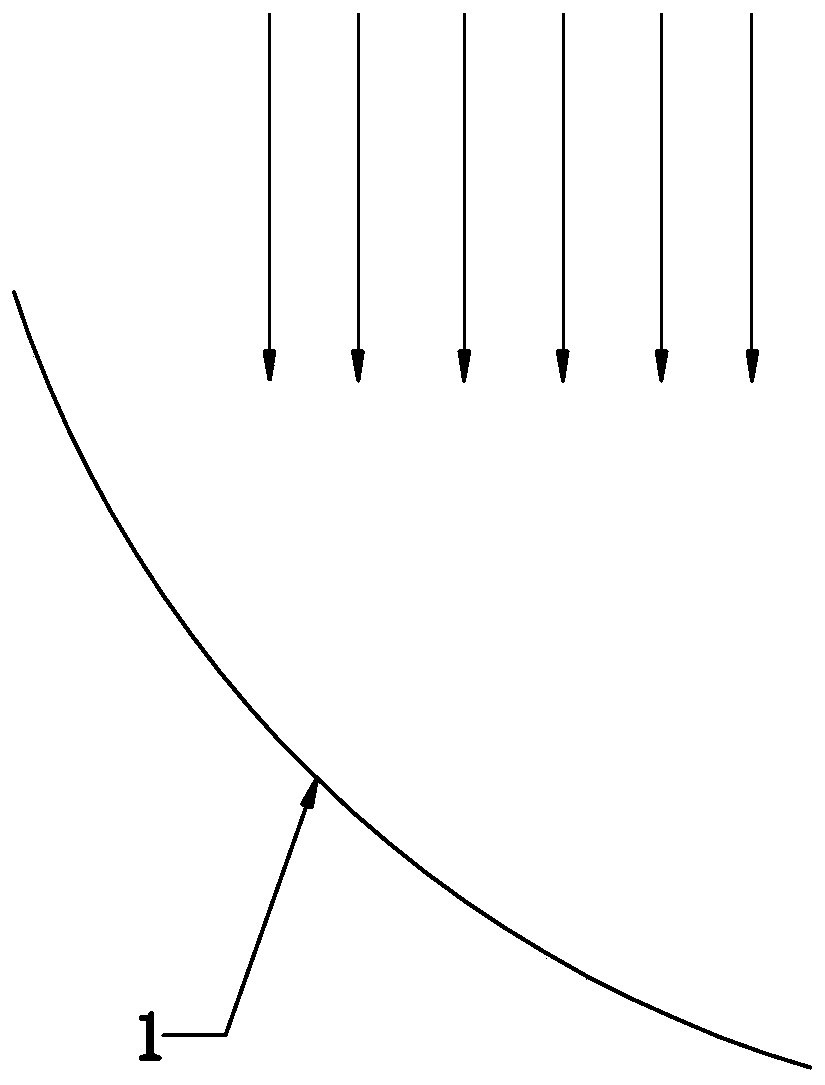

[0041] like Figure 1 ~ Figure 3As shown, the present invention discloses a solar concentrating lens, comprising a lens body 1, a concave surface 10 and a convex surface 11 arranged on both sides of the lens body 1, and an opening 12 arranged at the center of the lens body 1. In the present invention In the specific embodiment, it includes several reinforcing chambers 13 arranged inside the lens body 1 and distributed at equidistant intervals in the circumferential direction of the opening 12 and extending radially through the inner and outer rings of the lens body 1, and one end is installed A support module 2 that is in the opening 12 and is movably connected to the lens body 1, and a drive module 3 that is installed on the support module 2 and is used to control the movement of the lens body 1 with the opening 12 as the base point Wherein, the support module 2 includes a support shaft 20 with one end located in the opening 12, a first annular clamping piece 21 fixedly conne...

Embodiment 2

[0051] like Figure 4 ~ Figure 5 Shown, a kind of production method of solar concentrating lens, in the specific embodiment of the present invention, comprises the steps:

[0052] (1) cutting board: cutting the lens board into a plurality of circular lens embryos;

[0053] (2) Hole cutting: cutting an opening in the center of the lens embryo;

[0054] (3) Drill cavity: Utilize the cavity drill device to drill the cavity of the lens embryo that has passed through step (2), and each reinforcing cavity is formed by extending the edge of the lens embryo radially to the opening;

[0055] (4) grinding: the both sides of the lens embryo of step (3) are polished to form concave and convex surfaces;

[0056] (5) Laminating: Cover the prepared PVC film on the concave surface;

[0057] (6) Attachment installation: install the prepared supporting module and driving module on the lens embryo respectively;

[0058] (7) Spraying: Spray fluorocarbon paint on the installed lens embryo to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com