Coal mining machine rocker arm mechanical transmission system fault accurate positioning method

A mechanical transmission system and precise positioning technology, applied in the testing of mechanical components, testing of machine/structural components, special data processing applications, etc., can solve irregularities in the spectrum making process, misjudgments, and difficult temperature detection methods in the early stage Fault diagnosis and other issues, to achieve the best time-frequency resolution, accurate and precise positioning, to achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

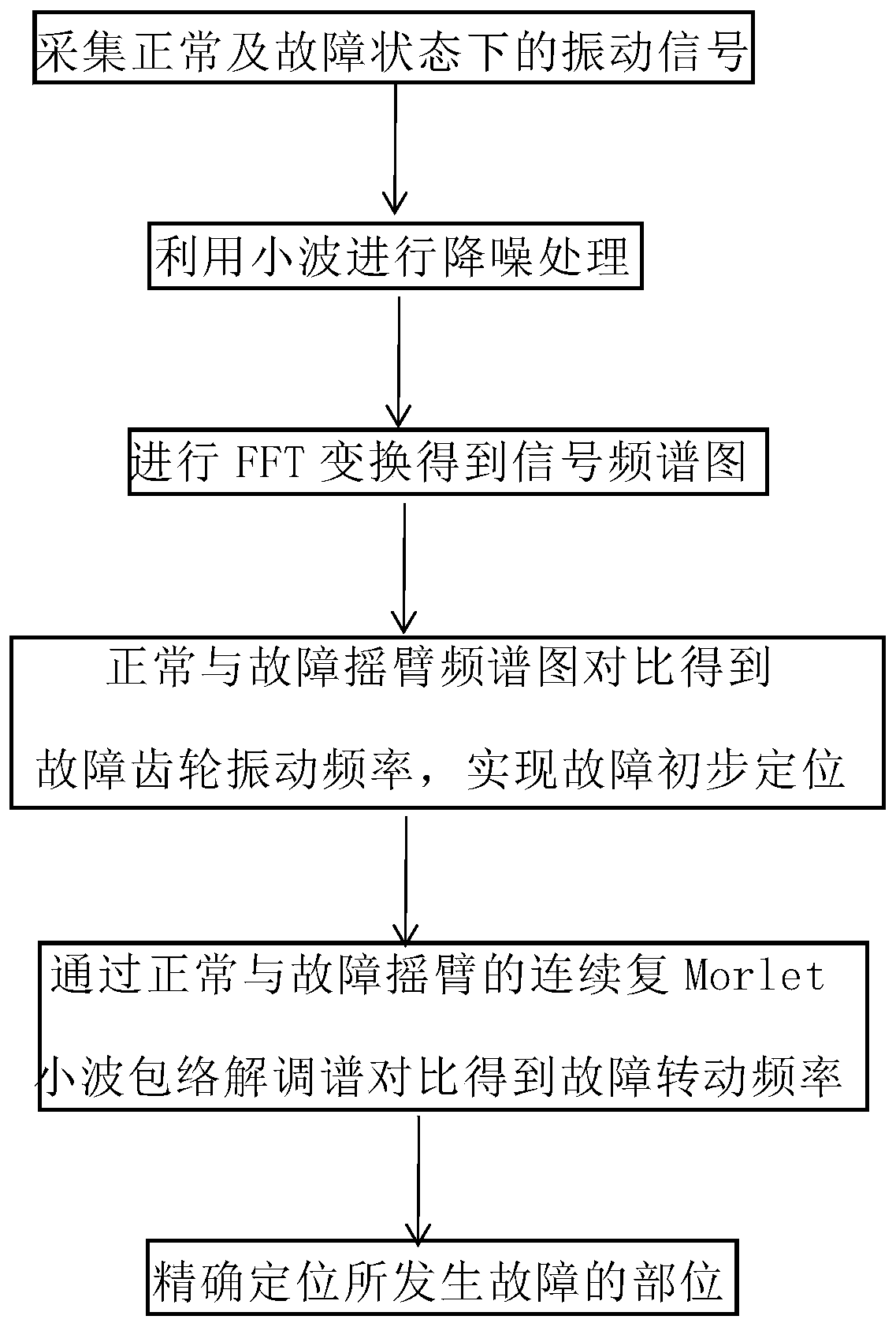

[0042] like figure 1 As shown, a method for accurately locating faults of a shearer rocker mechanical transmission system is characterized in that the method comprises the following steps:

[0043] Step 1, using wavelet to perform noise reduction processing on the collected vibration signal;

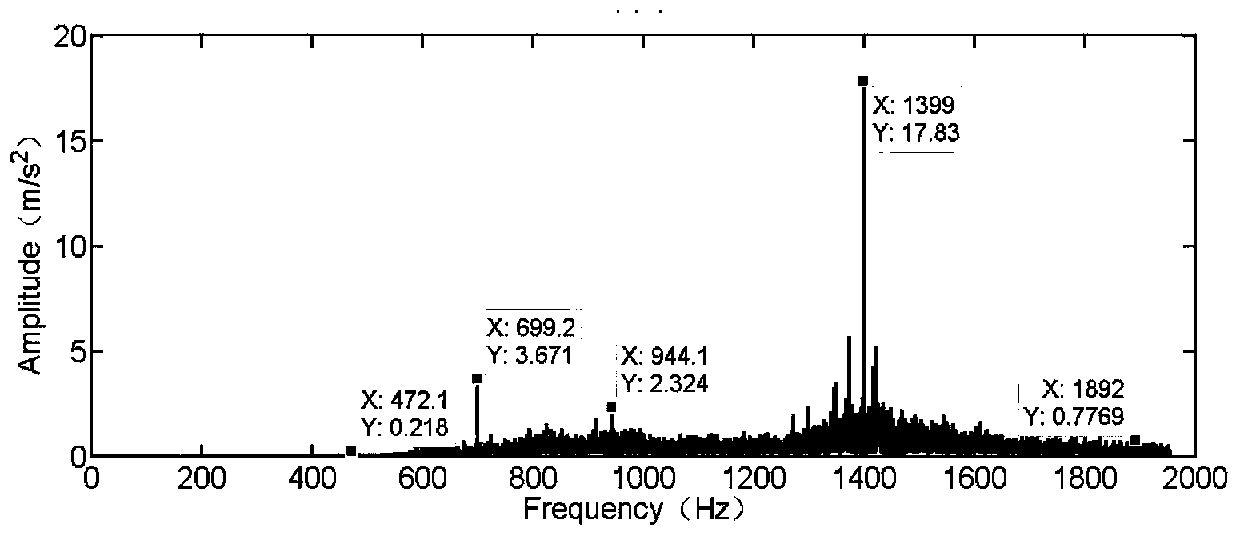

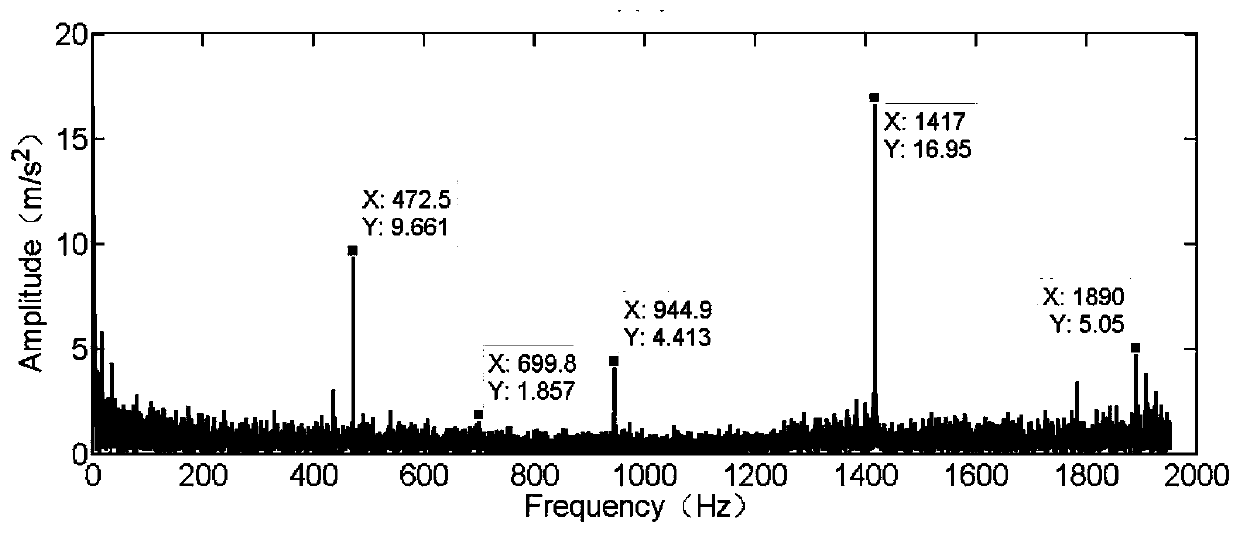

[0044] Step 2, performing FFT transformation on the noise-reduced vibration signal to obtain a spectrogram of the vibration signal;

[0045] Step 3: Compare and analyze the normal and faulty rocker arm spectrograms to obtain the vibration characteristic frequency of the faulty part, and initially locate the faulty part;

[0046] Step 301. The fault of the gear is mainly reflected in the rotation frequency and meshing frequency of the gear. The calculation formula of the rotation frequency is: f r =n / 60, where n is the rotational speed of the driving wheel, and the calculation formula of the meshing frequency is: f m =z×f r , where z is the number of gear teeth, f r is the rotational...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com