Cutting device

A cutting device and wafer segmentation technology, which is applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of high equipment cost, and achieve the effect of reducing equipment cost and realizing space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, a cutting device according to an embodiment of the present invention will be described in detail with reference to the drawings.

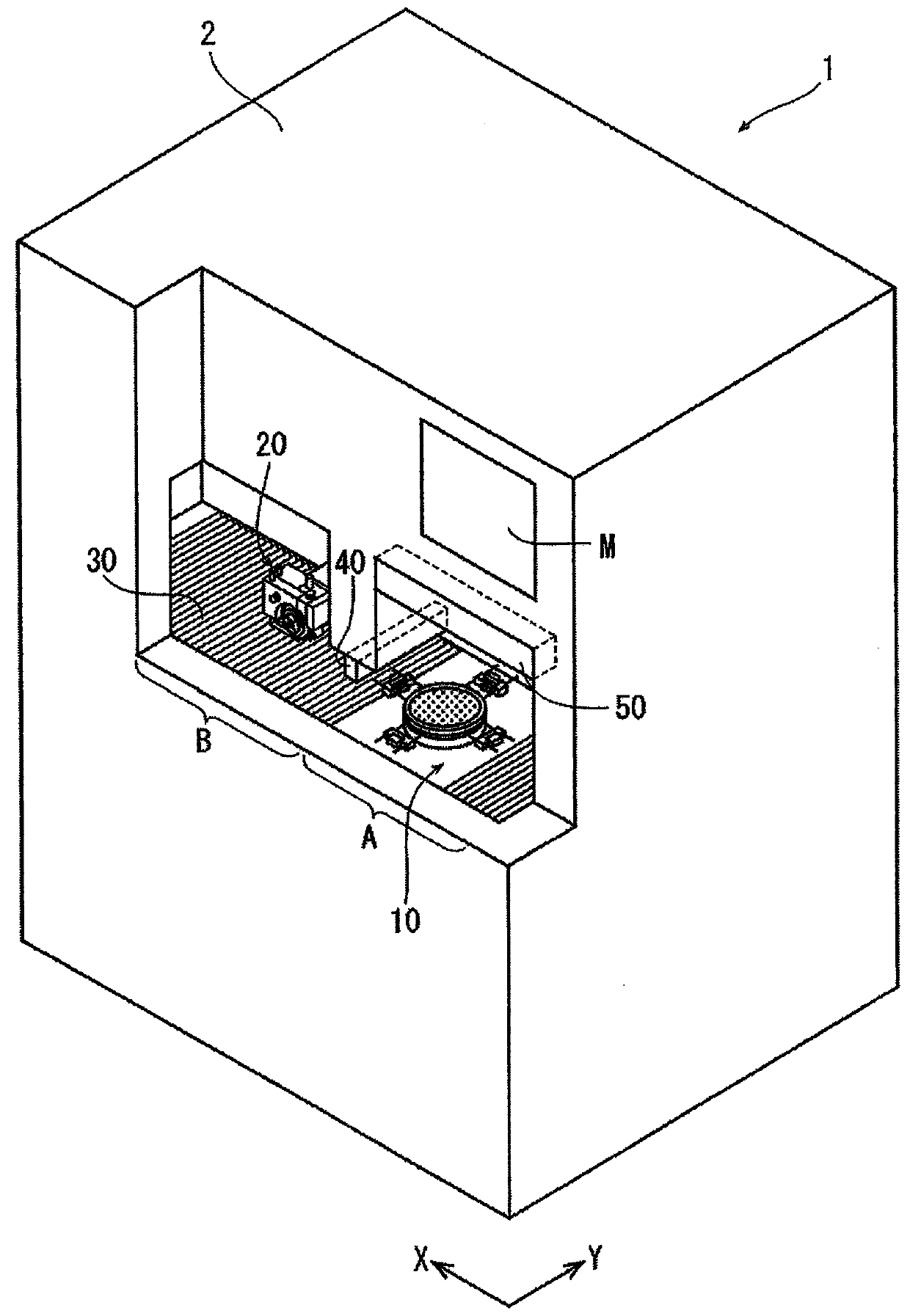

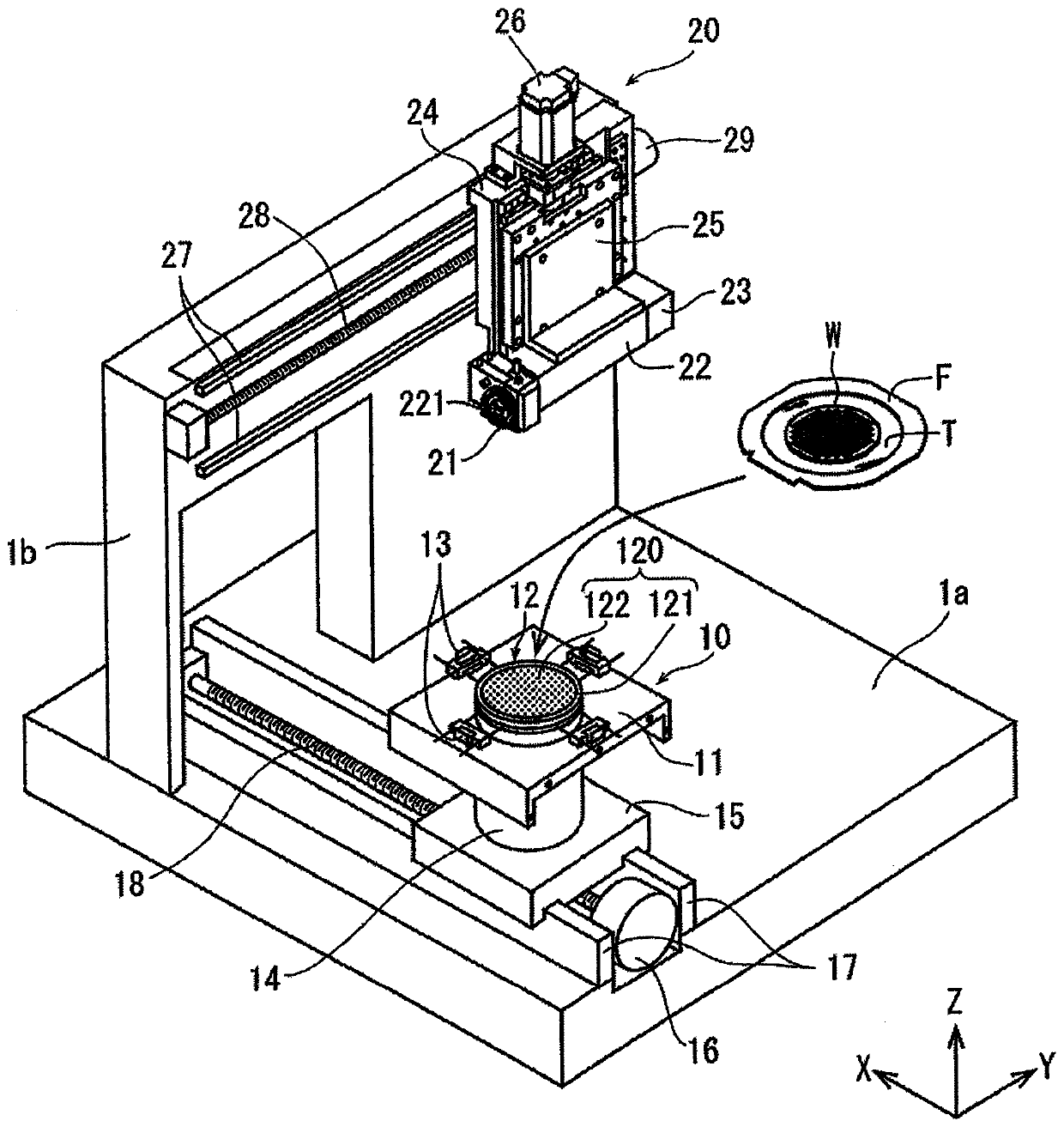

[0024] exist figure 1 shows an overall perspective view of the cutting device 1 of this embodiment, and figure 2 shown in figure 1 A perspective view of the main parts of the cutting device 1 is shown.

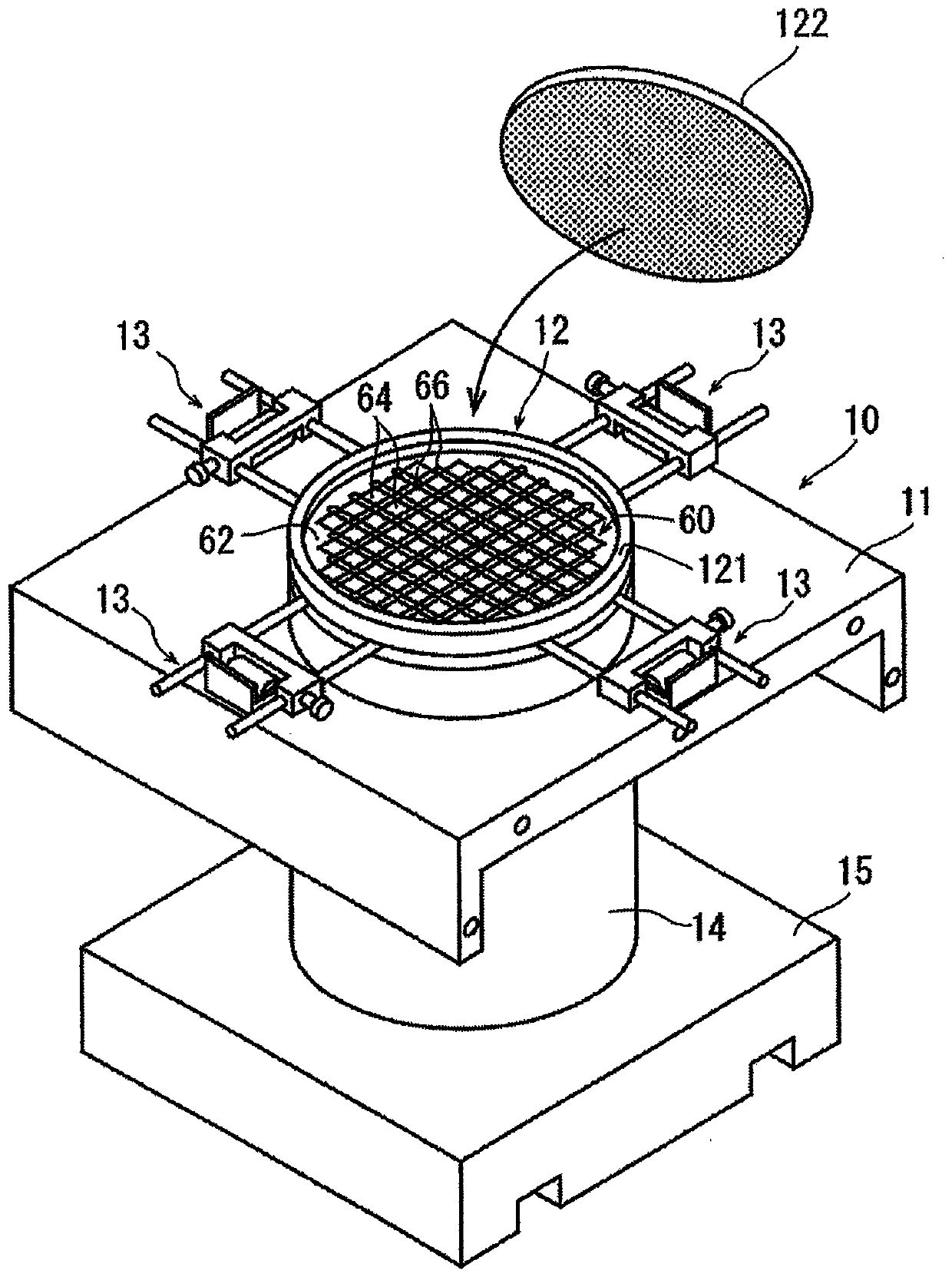

[0025] The cutting device 1 has the ability to place and hold the workpiece ( figure 2 The chuck table 10 of the wafer W) shown also has a cutting unit 20 for dividing the wafer W supported by the ring frame F via the respective adhesive tapes T into individual device chips.

[0026] Such as figure 1 As shown, the chuck table 10 can advance and retreat in the X-axis direction shown by the arrow X to be positioned in the loading and unloading area A and the processing area B. In the loading and unloading area A, a wafer W or wafer W is placed and held on the chuck table 10. The chipped wafer W is taken out from the chuck t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com