Anti-wire falling damping spring damper

A technology of damping springs and anti-vibration hammers, applied in the field of transmission lines, to achieve the effects of reducing wear, dispersing large forces, and preventing loosening and slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

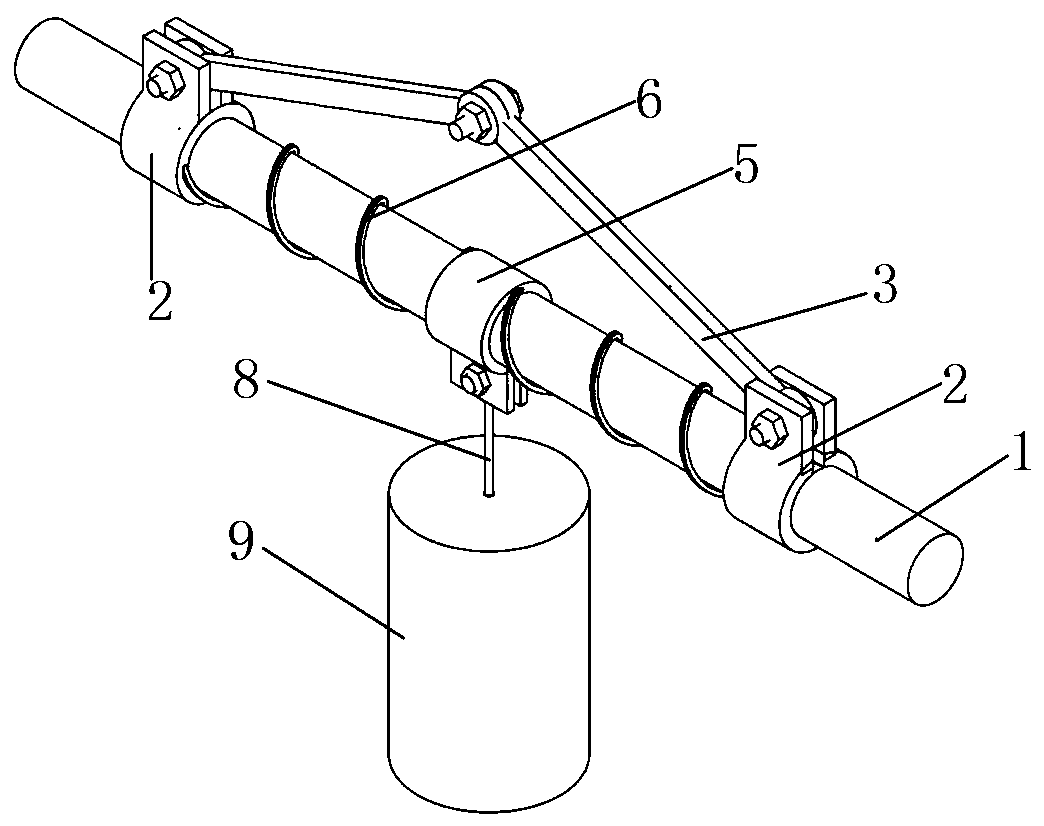

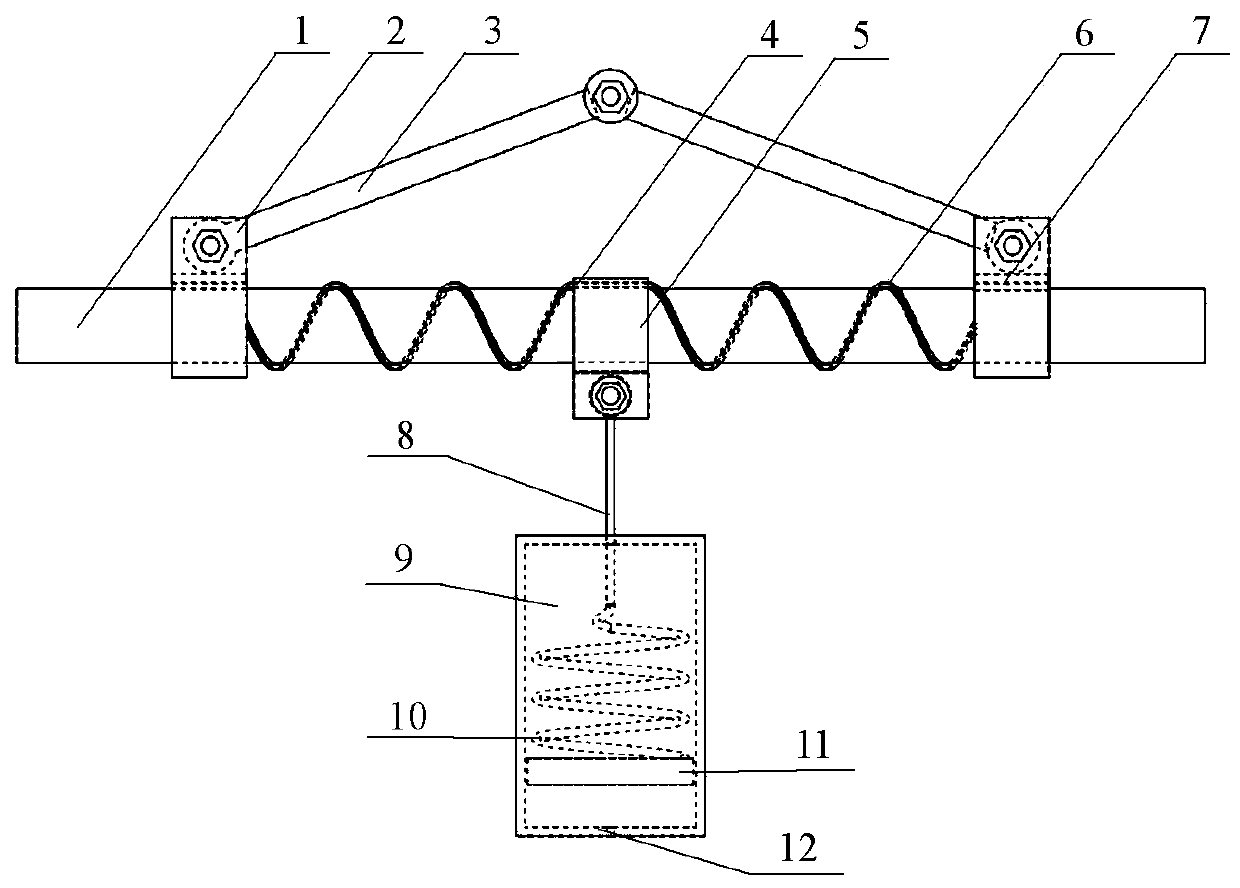

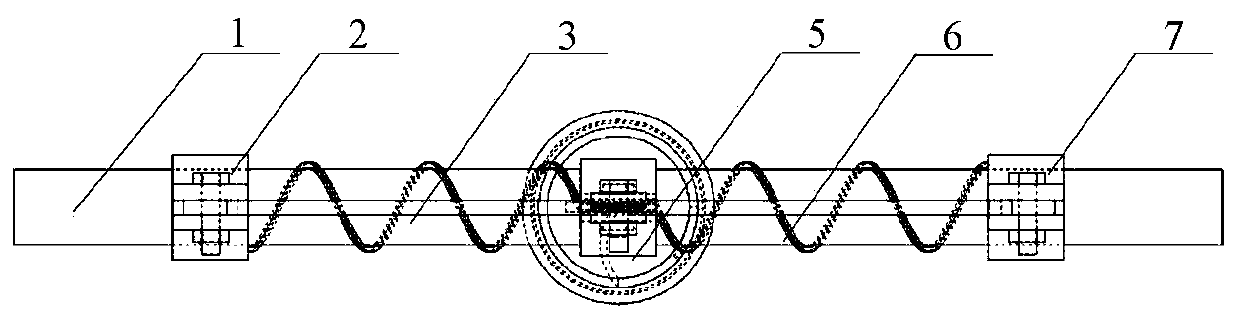

[0020] Example: see figure 1 , figure 2 , image 3 with Figure 4 , in the figure, 1-wire, 2-connecting mechanism clamp, 3-connecting mechanism, 4-through hole, 5-anti-vibration hammer clamp, 6-pre-twisted wire, 8-anti-vibration hammer connecting rod, 9-anti-vibration hammer Vibrating hammer barrel, 10-damping spring, 11-counterweight plate, 12-drainage hole.

[0021] Damping spring anti-vibration hammer for anti-dropping, including anti-vibration hammer clamp and anti-vibration hammer. The anti-vibration hammer is connected with the anti-vibration hammer clamp and fixed on the wire through the anti-vibration hammer clamp. The damping spring is used to assist in dissipating vibration energy , through the pre-twisted wire that runs through the anti-vibration hammer clamp to provide vibration damping and buffering, which can reduce the wear of the cable at the anti-vibration hammer clamp, and at the same time provide backup protection for broken wires at the anti-vibration h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com