Underwater cleaning machine

A machine and cleaning technology, applied in the direction of ship cleaning devices, cleaning methods and tools, cleaning methods using tools, etc., can solve problems such as inconvenient manpower, and achieve the effect of cost saving and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

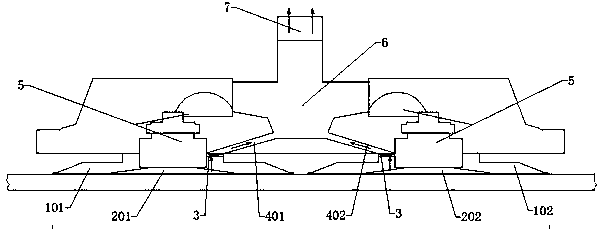

[0038] An underwater cleaning machine for cleaning panels in an underwater environment, comprising:

[0039] The cleaning part includes a first cleaning part and a second cleaning part, the space defined by the first cleaning part and the plate is the first space, and the space defined by the second cleaning part and the plate is the second space;

[0040] A connecting arm, one end of the connecting arm is equipped with a first cleaning element, and the other end is equipped with a second cleaning element;

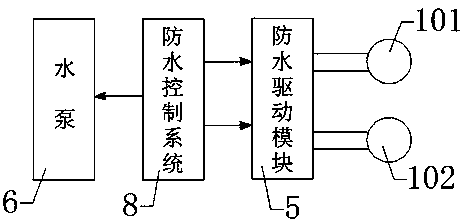

[0041] The motor drive module is electrically connected to the cleaning piece to drive the rotation of the first cleaning piece and the second cleaning piece;

[0042] a control system module, coupled to the motor drive module to issue execution instructions;

[0043] The connecting arm, the first cleaning part, the second cleaning part, the motor drive module and the control system module are installed on the housing;

[0044] The motor drive module is set as a waterpro...

specific Embodiment approach

[0055] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: Cleaning material 1 is provided on the cleaning part 1 to remove particulate impurities when the cleaning machine is adsorbed on the underwater plate. In the initial working state, the waterproof control system module 8 sends a signal instruction, and the water pump 6 starts to extract the first space 201 and the second space 202 defined by the two cleaning parts and the plate through the first water inlet pipe 401 and the second water inlet pipe 402 respectively. The water in the water is discharged to the water outlet 7. At this time, the valves 3 in the water inlet pipe 4 are all open, so that the first space 201 and the second space 202 form a negative pressure, and the entire cleaning machine is adsorbed on the underwater plate.

[0056] When the cleaning work is started, the waterproof control system module 8 sends signal instructions to the water pump 6 and the waterproof motor drive module 5 respectively, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com