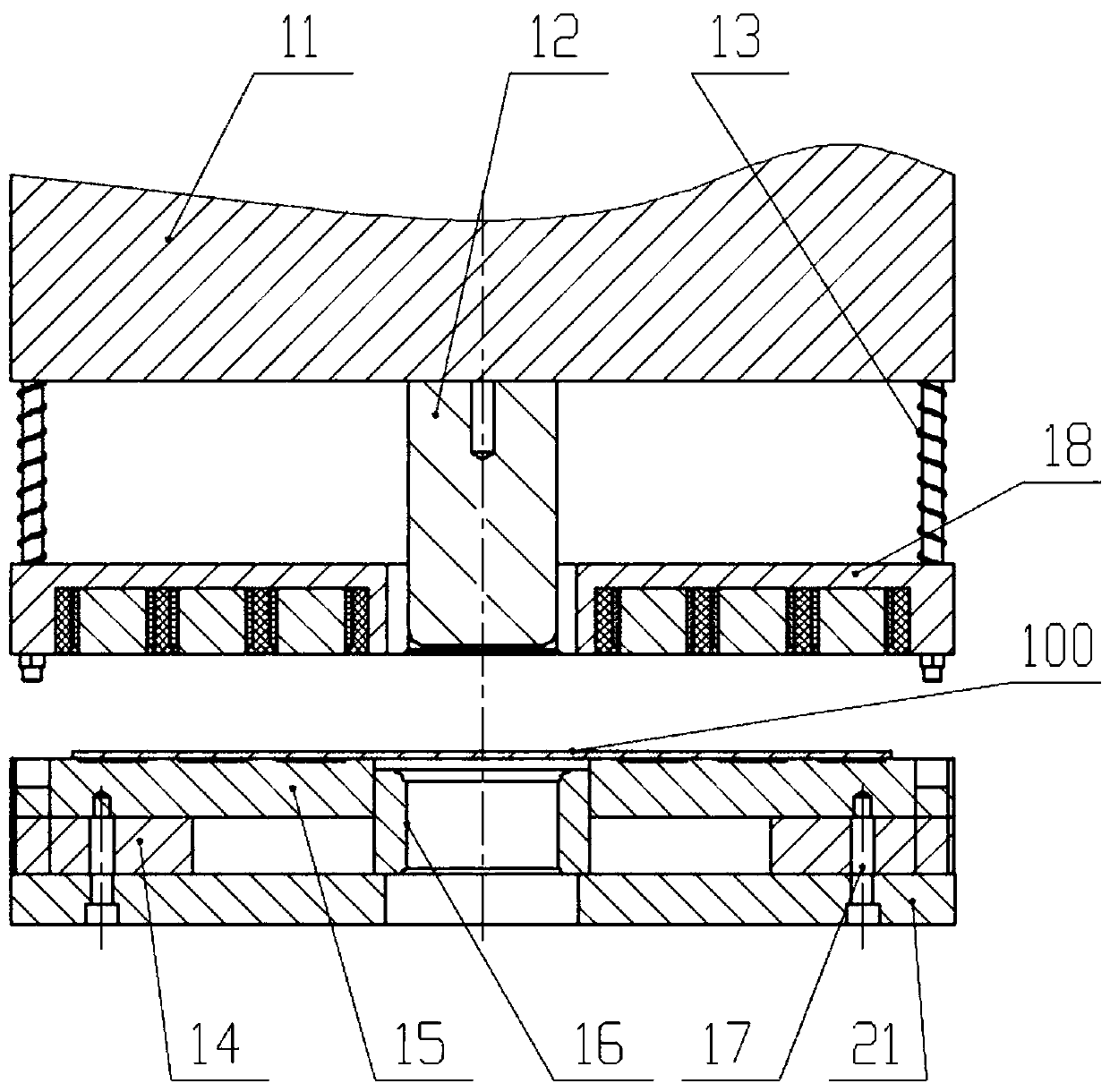

Block edge pressing device based on electric control permanent magnet technology and edge pressing force control method

An electronically controlled permanent magnet and blank-holding device technology, which is applied in the field of blank-holding devices, can solve the problems affecting the quality of slab deep-drawing and the inability to realize precise control of blank-holding force, so as to provide forming effect and forming limit, and greatly promote Prospects and social needs, the effect of energy saving and calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

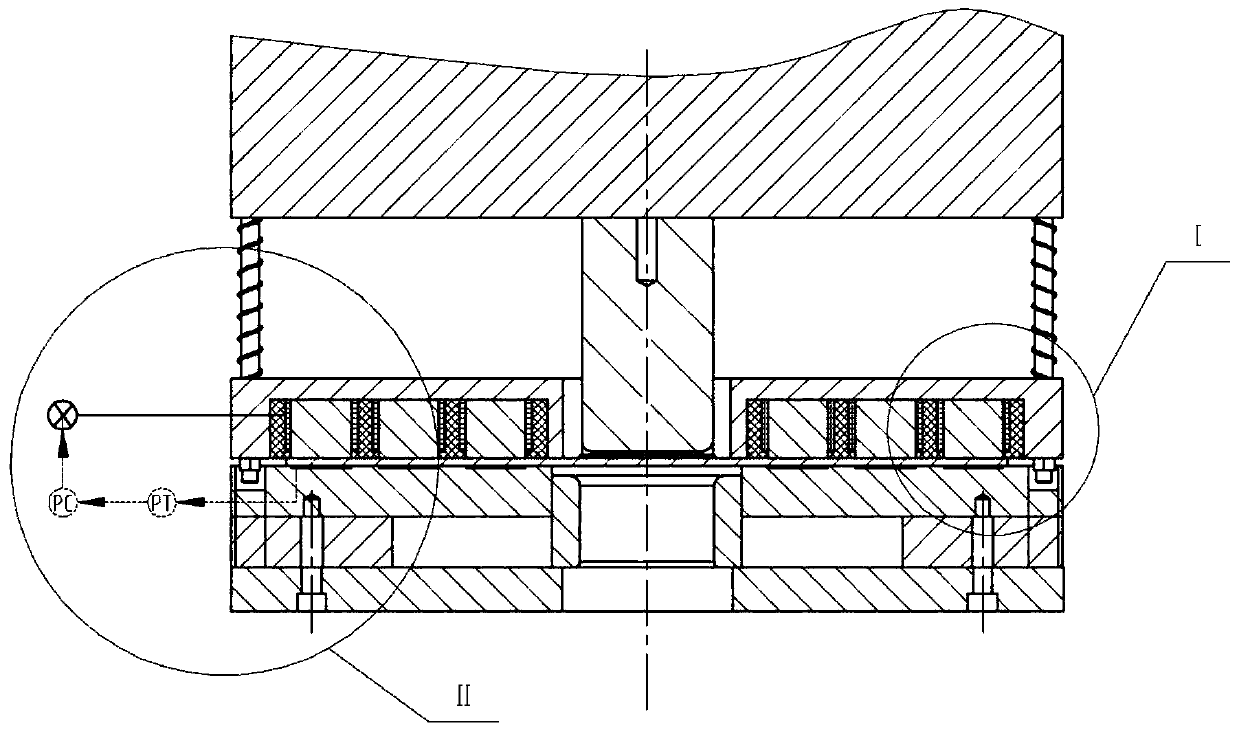

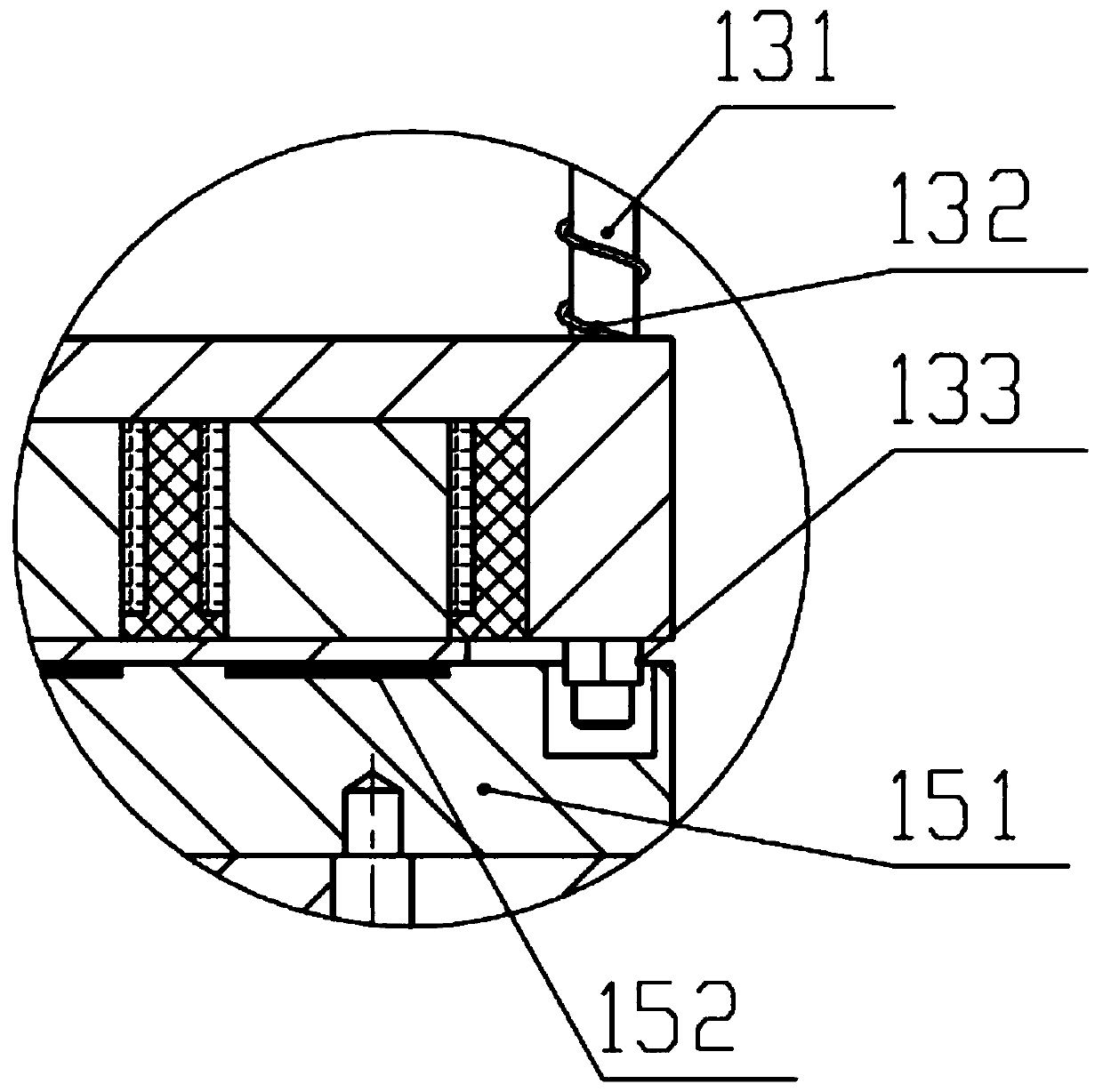

[0058] press the whole system figure 2 As shown in the connection, when the drawing is in progress, if the wrinkling tendency at a certain position increases, the pressure value measured by the pressure sensor will increase. After the measured value is passed to the controller, the controller will give an output value according to the PID control law , this output value control circuit regulator will input a higher current intensity value to this area, so that the coil wound on the permanent magnet will generate an instantaneous electromagnetic field to increase the external magnetic force of the permanent magnet. Under the action, the blank holder force here increases enough to suppress the occurrence of wrinkling.

Embodiment 2

[0060] When deep drawing is in progress, if the wrinkling tendency at a certain position decreases, the pressure value measured by the pressure sensor will decrease. After the measured value is passed to the controller, the controller will give an output value according to the PID control law. The output value control circuit regulator will input a certain low current intensity value to this area, so that the coil wound on the permanent magnet will generate an instantaneous electromagnetic field to reduce the external magnetic force of the permanent magnet. Next, the blank holder force is reduced here in order to increase the height of deep drawing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com