Forging method capable of reducing curvature of slender steel

A bending degree and steel technology, which is applied in the field of steel forging, can solve the problems that slender steel is easy to bend, etc., and achieve the effect of reducing the number of preheating and straightening and rectification, saving manufacturing costs, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a forging forming method for reducing the curvature of the steel when the precision forging machine forges the slender steel.

[0028] A 16MN horizontal precision forging machine is adopted, the programming software for automatic control is BarForge, and the model of the round hammer head is R120 or R150. Requirements for forging round billets: the weight of the billet must be ≤8 tons, the length of the billet must be >1.5 meters, the initial diameter of the billet must be less than Φ690mm (only for bending), the length of the finished product must be ≤20 meters, and the minimum diameter of the finished product is Φ120mm.

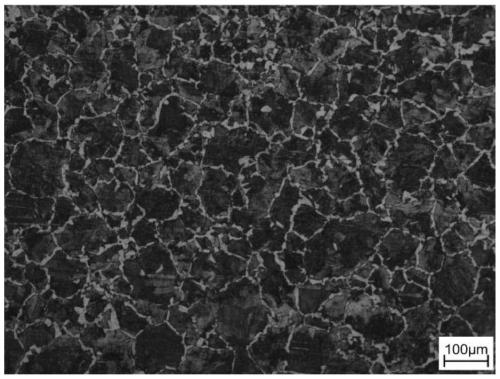

[0029] The blank used in this example is H13 die steel, with a weight of 3.17 tons and a specification of The forged product is H13 die steel with a specification of Φ200+2 / -0*12000mm. The specific preparation process of the product is: blank→heating→forging to the finished product size with a precision forging machine.

...

Embodiment 2

[0054] This embodiment provides a forging forming method for reducing the curvature of the steel when the precision forging machine forges the slender steel.

[0055] A 16MN horizontal precision forging machine is adopted, the programming software for automatic control is BarForge, and the model of the round hammer head is R120 or R150. Requirements for forging round billets: the weight of the billet must be ≤8 tons, the length of the billet must be >1.5 meters, the initial diameter of the billet must be less than Φ690mm (only for bending), the length of the finished product must be ≤20 meters, and the minimum diameter of the finished product is Φ120mm.

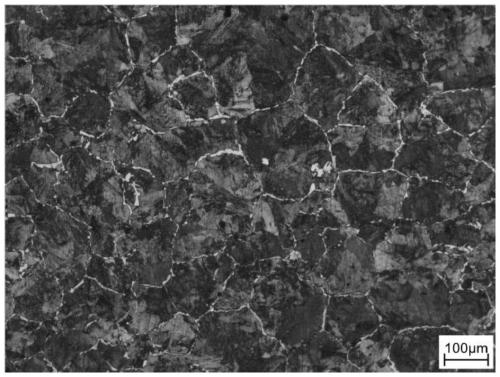

[0056] The blank used in this embodiment is 42CrMo bonded steel with a weight of 1.78 tons and a specification of The forged product is 42CrMo bonded steel with a specification of Φ150+2 / -0*12000mm. The specific preparation process of the product is: blank→heating→forging to the finished product size with a precision forgin...

Embodiment 3

[0071] This embodiment provides a forging forming method for reducing the curvature of the steel when the precision forging machine forges the slender steel.

[0072] A 16MN horizontal precision forging machine is adopted, the programming software for automatic control is BarForge, and the model of the round hammer head is R120 or R150. Requirements for forging round billets: the weight of the billet must be ≤8 tons, the length of the billet must be >1.5 meters, the initial diameter of the billet must be less than Φ690mm (only for bending), the length of the finished product must be ≤20 meters, and the minimum diameter of the finished product is Φ120mm.

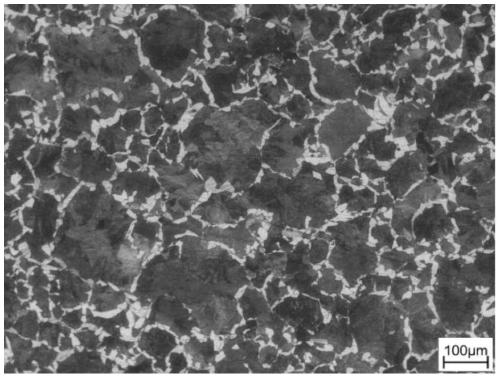

[0073] The blank used in this example is D-SFCM860-1 structural steel, with a weight of 3.7 tons and a specification of The forged product is D-SFCM860-1 structural steel with a specification of Φ180+2 / -0*18000mm. The specific preparation process of the product is: blank→heating→forging to the finished product size with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com