Full-automatic embossing equipment for garment fabric

A fully automatic, fabric technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of low degree of automation, inability to achieve continuous automatic spreading, etc., to ensure accuracy, no wrinkles, and improve adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

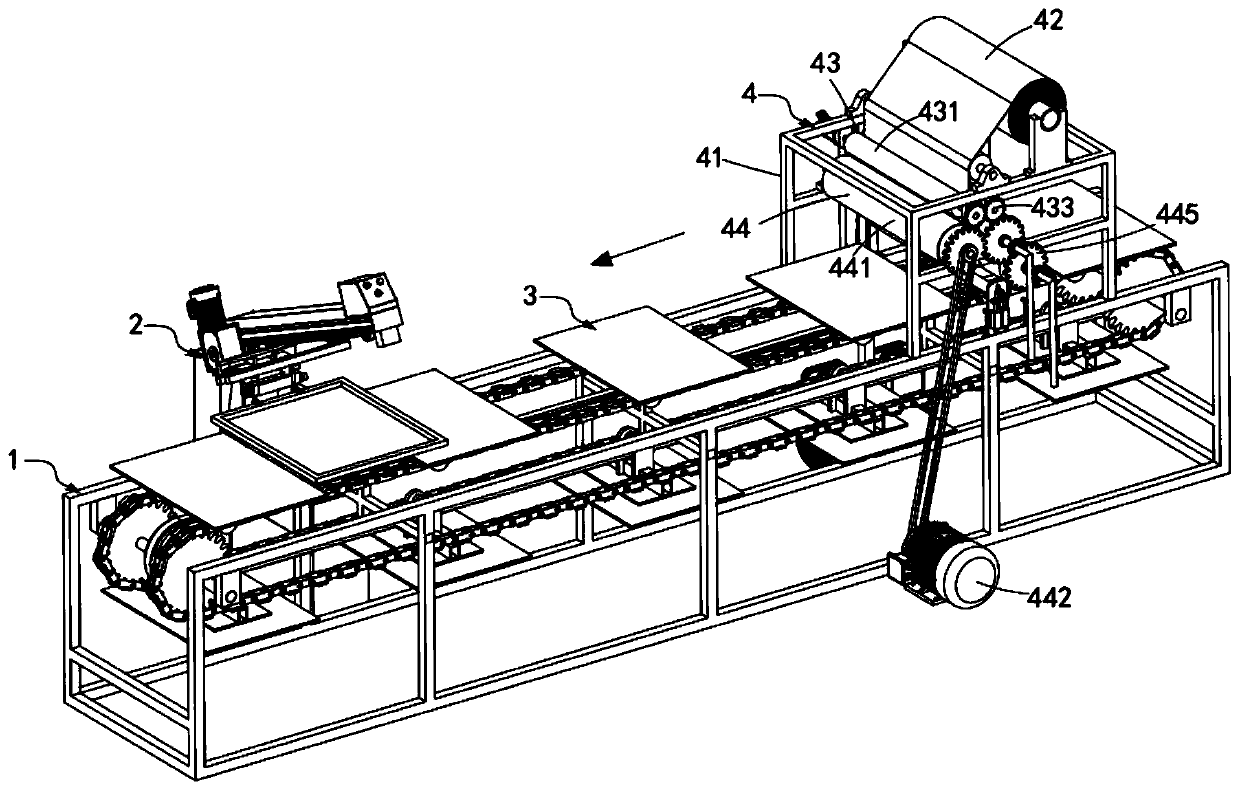

[0077] Such as Figure 1 to Figure 8 As shown, a fully automatic printing equipment for clothing fabrics, including a conveying line 1 and at least one set of printing devices 2 arranged on the conveying path of the conveying line 1, the conveying line 1 is conveyed horizontally and straightly, and it is rotated up and down, and It drives a horizontally arranged deck 3 conveyor and also includes:

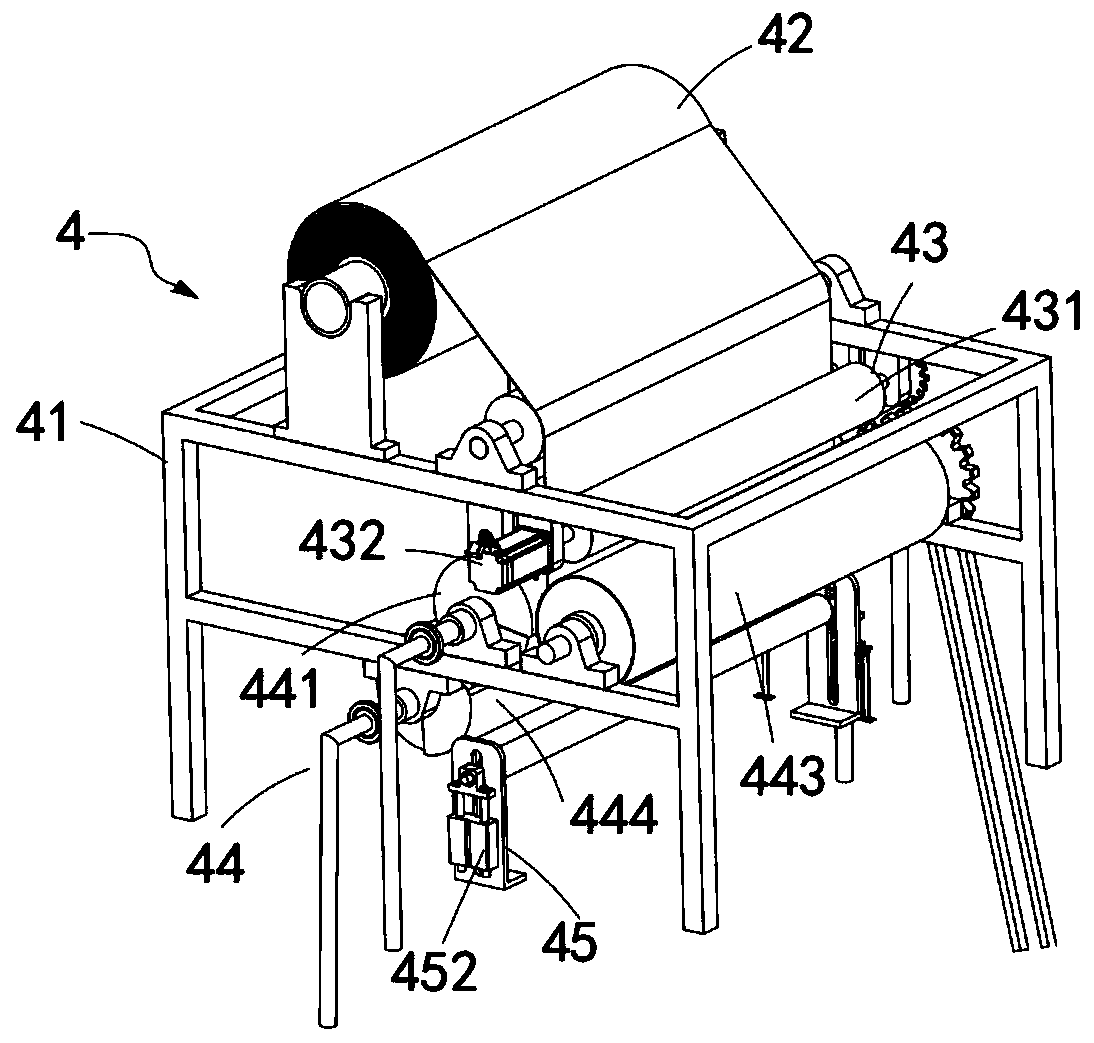

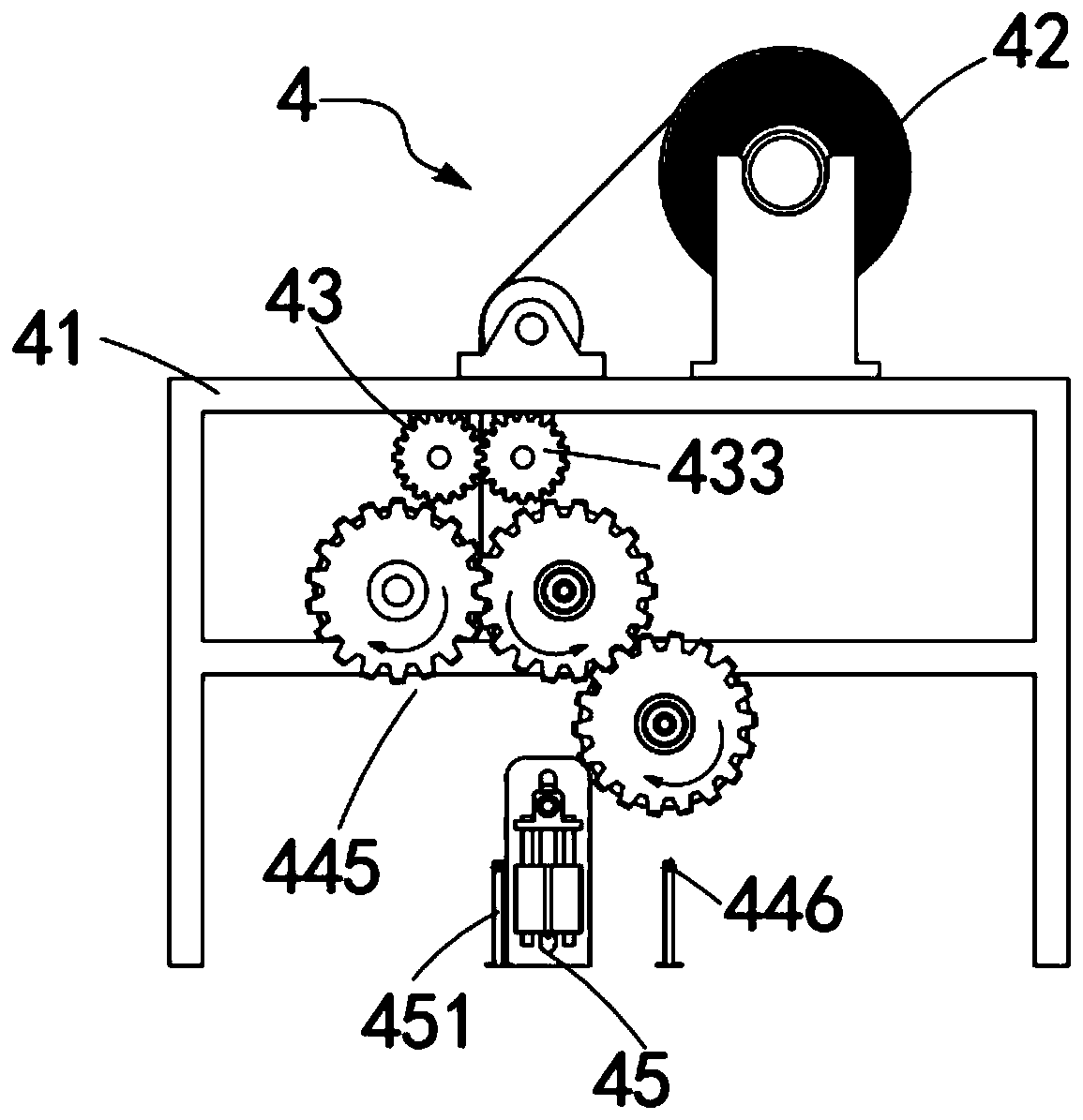

[0078] Automatic feeding device 4, described automatic feeding device 4 is installed on the top of described conveying line 1, and it comprises mounting frame 41, the material roll 42 that is placed on the top of mounting frame 41, the unwinding mechanism 43 that is positioned at material roll 42 below , the cutting transfer mechanism 44 located below the unwinding mechanism 43 and the pressing mechanism 45 located below the cutting transfer mechanism 44, the two ends of the material roll 42 are erected on the mounting frame 41, and are freely rotatable. The output end of the mater...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap