Steaming unit equipped with elastic sealing device, and dyeing machine

A technology of elastic sealing and elastic sealing strips, which is applied in the sealing of engines, printing machines, mechanical equipment, etc., and can solve the problems of light color yield of fabrics, low utilization rate of dyestuffs, and escape of steam and dyeing liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

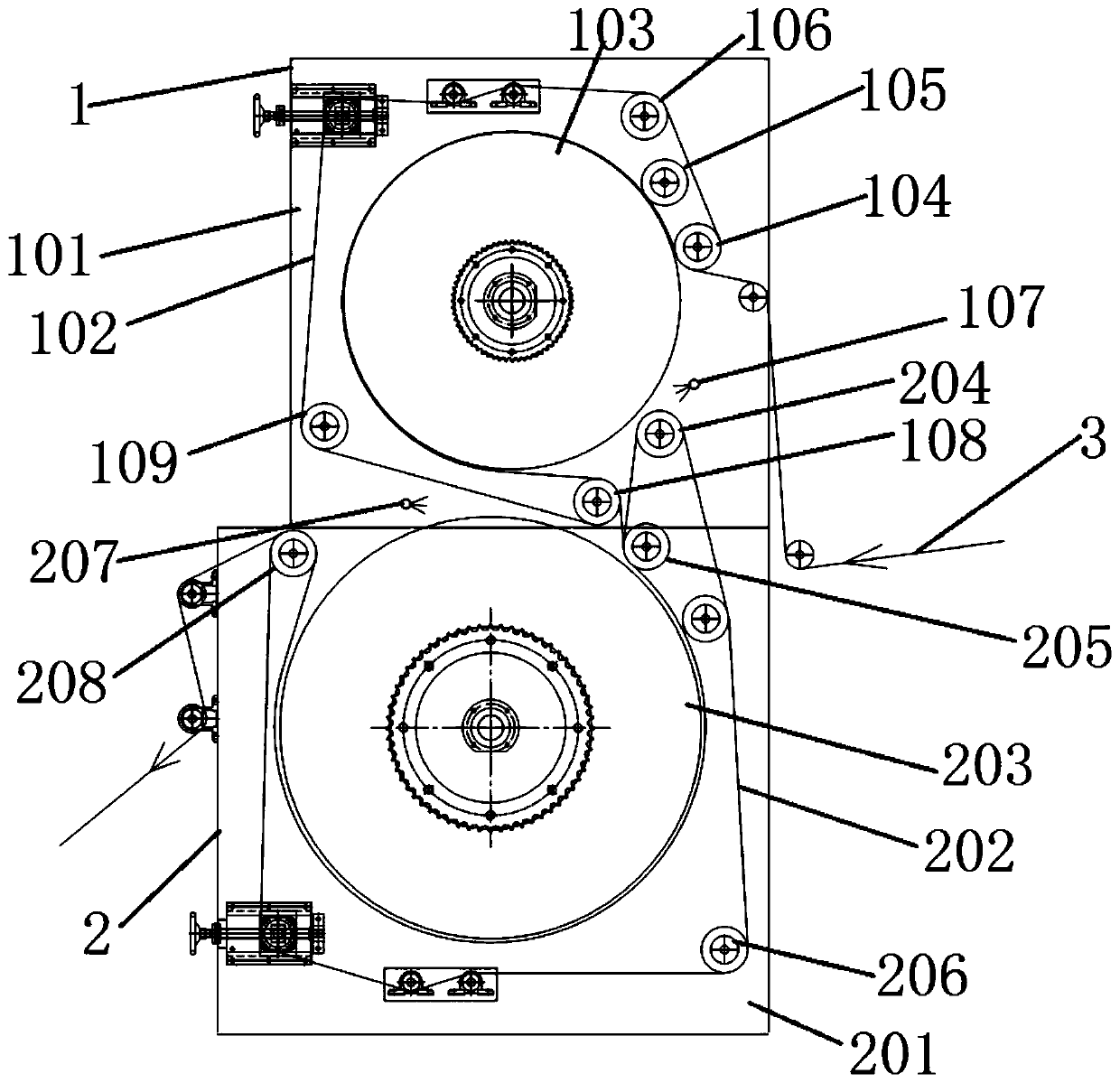

[0055] see Figure 1 to Figure 5 and Figure 9 to Figure 11 , a steaming unit provided with an elastic sealing device provided in this embodiment, comprising:

[0056] Cloth front steaming device 1 arranged sequentially along the conveying direction of the cloth;

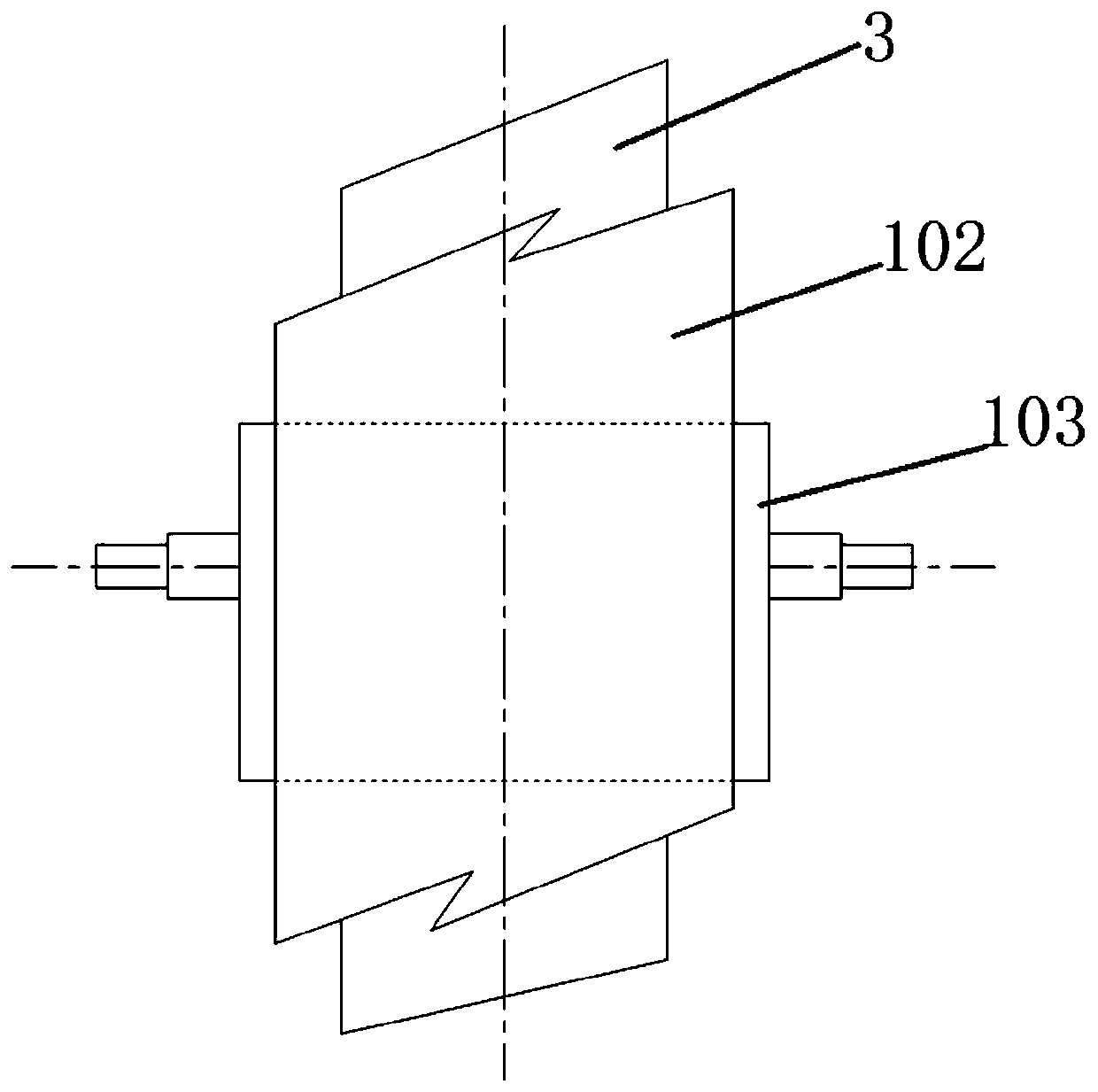

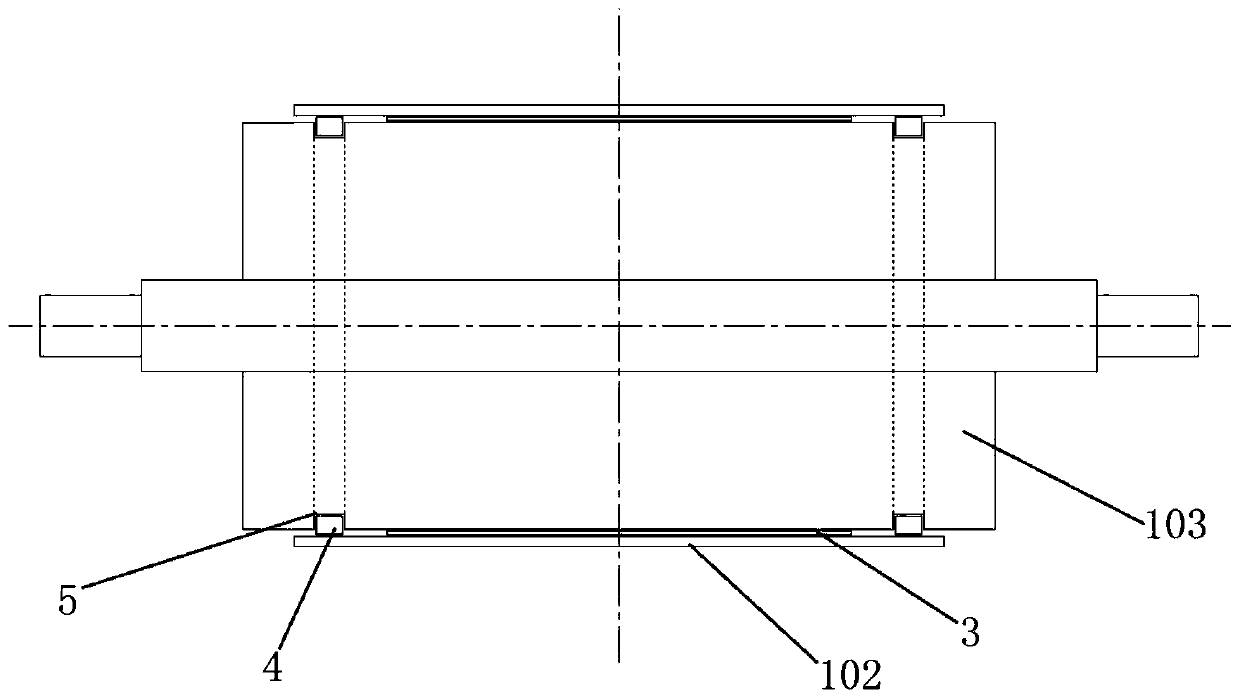

[0057] The cloth front steaming device 1 includes a first frame 101, a first drive assembly, a first heating wheel 103, a first high temperature resistant conveyor belt 102, a first inlet pressure wheel 105 and a first support wheel 106 group, the The first driving assembly is arranged on the first frame 101, the first driving assembly is connected with the first heating large wheel 103, and the first driving assembly is used to drive the first heating large wheel 103 Rotate, the first inlet pressure wheel 105 is one or more, the first support wheel 106 group includes a plurality of first support wheels 106 and the first inlet support wheel 104 and the first outlet support wheel 108, the first A high-temperature-...

Embodiment 2

[0106] see Figure 1 to Figure 11 , a dyeing machine provided in this embodiment, comprising a cloth sending device 6, a finished product collecting device 7, and a double-sided steaming unit according to any one of claims 1 to 5, the cloth sending device 6, the cloth The front steaming device 1 , the cloth reverse steaming device 2 and the finished product collecting device 7 are arranged in sequence along the conveying direction of the cloth.

[0107] Further, it also includes a cooling device 9 arranged between the cloth reverse side steaming device 2 and the finished product collecting device 7, and the cooling device 9 is a cooling wheel group cooling device 9 or a single-sided air-cooled cooling device 9 or a double-sided air-cooled Cooling device 9.

[0108] Further, it also includes a double-sided printing and pad coating device 8 or a single-sided printing and pad coating device arranged between the cloth sending device 6 and the cloth front steaming device 1;

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com