Intelligent mine mining model test system under multi-field coupling

A model test and intelligent technology, applied in ground mining, earth square drilling, underground mining, etc., can solve the problem of seldom considering the influence of simulated inclined rock formations, the inability to simultaneously simulate the mine mining process, and the difficulty in simulating the automatic mining process of automatic excavation working faces, etc. problems, to achieve the effect of avoiding resource waste and real-time and precise control of the mining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

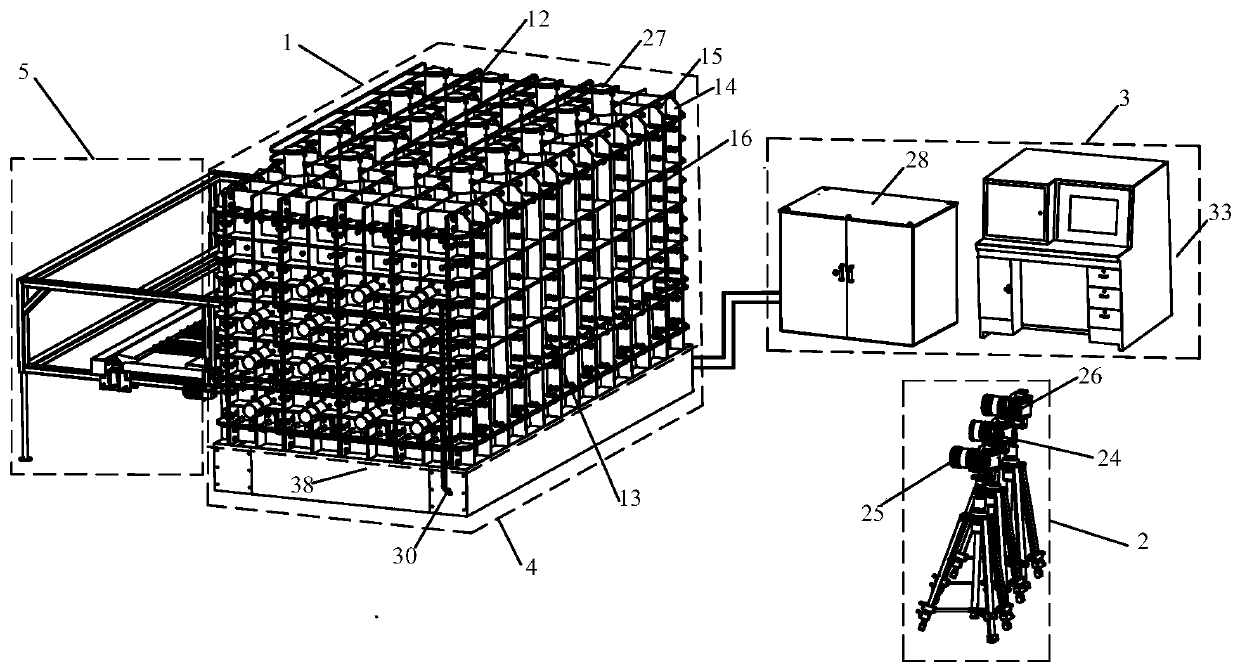

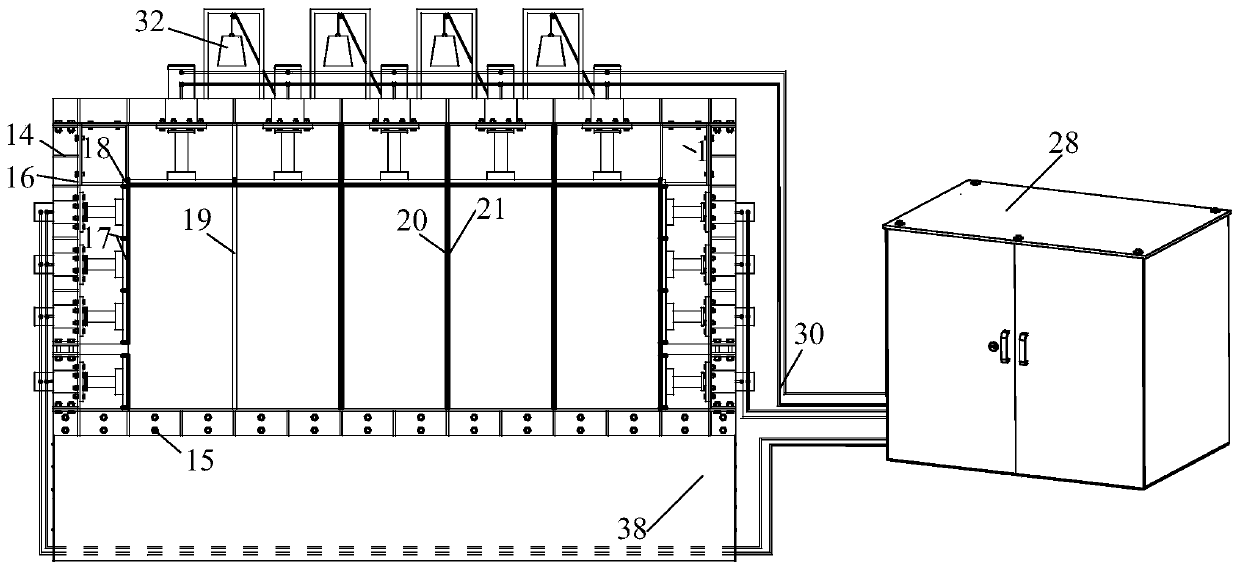

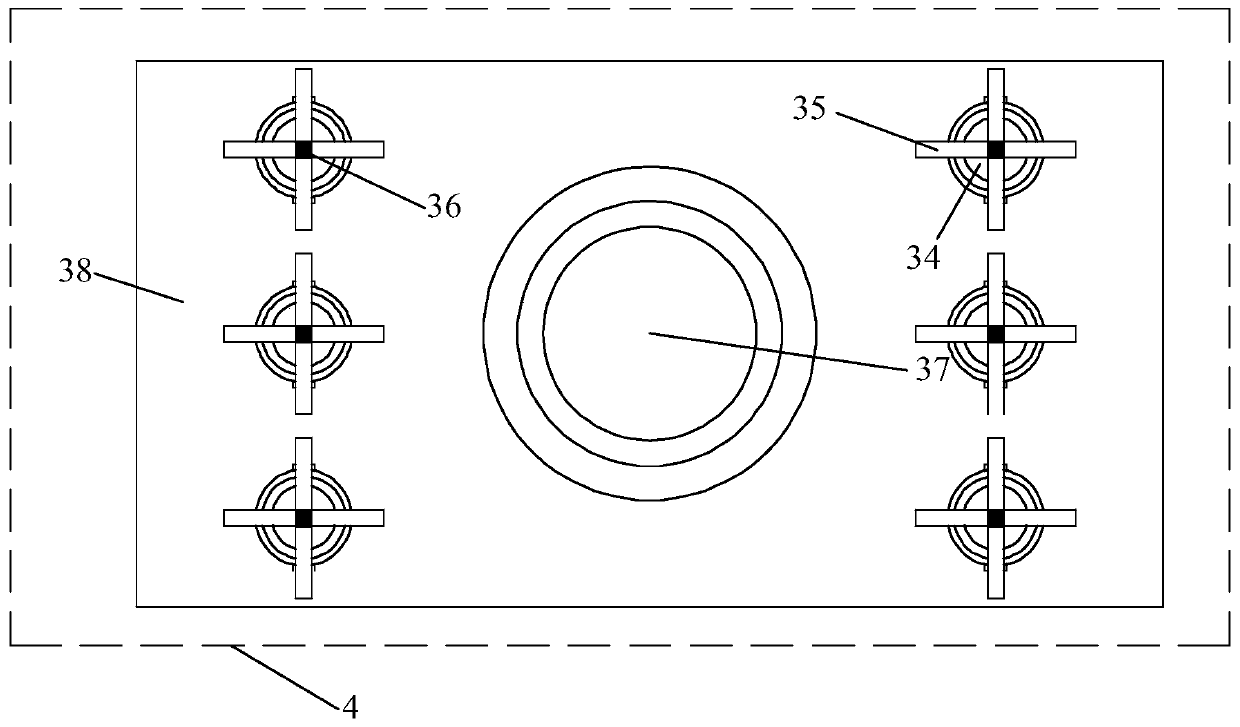

[0055] Attached below figure 1 - attached Figure 9 The test system disclosed in this embodiment is further described;

[0056] Refer to attached figure 1 As shown, a multi-field coupled mine intelligent mining model test system that can simulate slip faults, inclined rock formations, realize modularization, high-precision synchronous real-time monitoring, automatic coal mining and roadway profiling excavation is mainly composed of a combined sealing reaction force device 1. High-precision real-time synchronous monitoring system 2. Dynamic and static combined high-precision hydraulic control system 3. Intelligent inclined rock formation simulation device 4. Automatic coal mining and roadway profiling excavation system 5.

[0057] The multi-field coupled mine intelligent mining model test system is equipped with a fault simulation device 6, a temperature regulation system 7, an air volume regulation system 8, a high-precision gas control system 9, a high-precision water stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com