Steam turbine lubricating oil system pipeline flushing method

A pipeline flushing and lubricating oil technology, which is applied to chemical instruments and methods, cleaning methods and utensils, mechanical equipment, etc., can solve the problems of time-consuming and manpower consumption, loss of lubricating oil, jamming of the speed control system, etc., and reduce hard The effect of removing impurities such as grains, prolonging the service life, and advancing the completion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

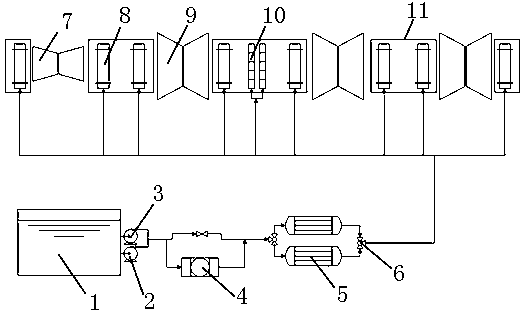

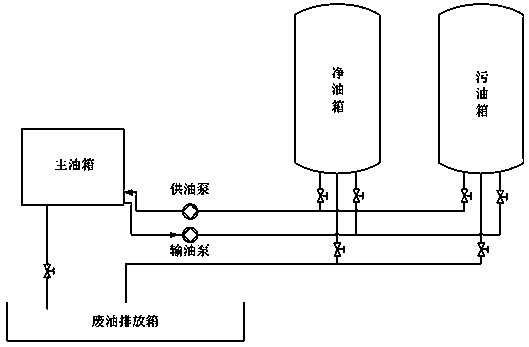

[0049] like figure 2 and 3 As shown, the steam turbine lubricating oil system of the present application may include a main oil tank 1, an AC lubricating oil pump 2 and a DC lubricating oil pump 3 arranged in parallel, a filter 4 and a straight-through valve arranged in parallel, two oil coolers 5 arranged in parallel, and a bearing box 11. Low-pressure cylinder 7, high-pressure cylinder 9, clean oil tank, dirty oil tank, oil delivery pump, oil supply pump and waste oil discharge box.

[0050]The main oil tank 1 is equipped with an oil return filter, the inlet and outlet ports of the AC lubricating oil pump 2 and the DC lubricating oil pump 3 arranged in parallel are connected with the main oil tank 1 through the oil supply pipeline, and the filter 4 and the straight-through valve arranged in para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com