A low flow resistance prerotation phase muffler and its design method

A design method and technology for mufflers, applied in mechanical equipment, machines/engines, metal processing equipment, etc., can solve the problems of affecting equipment performance, chaotic flow field, and large flow loss of mufflers, so as to achieve uniform and controllable airflow flow and turbulent airflow. Weak vortex ability, the effect of improving aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

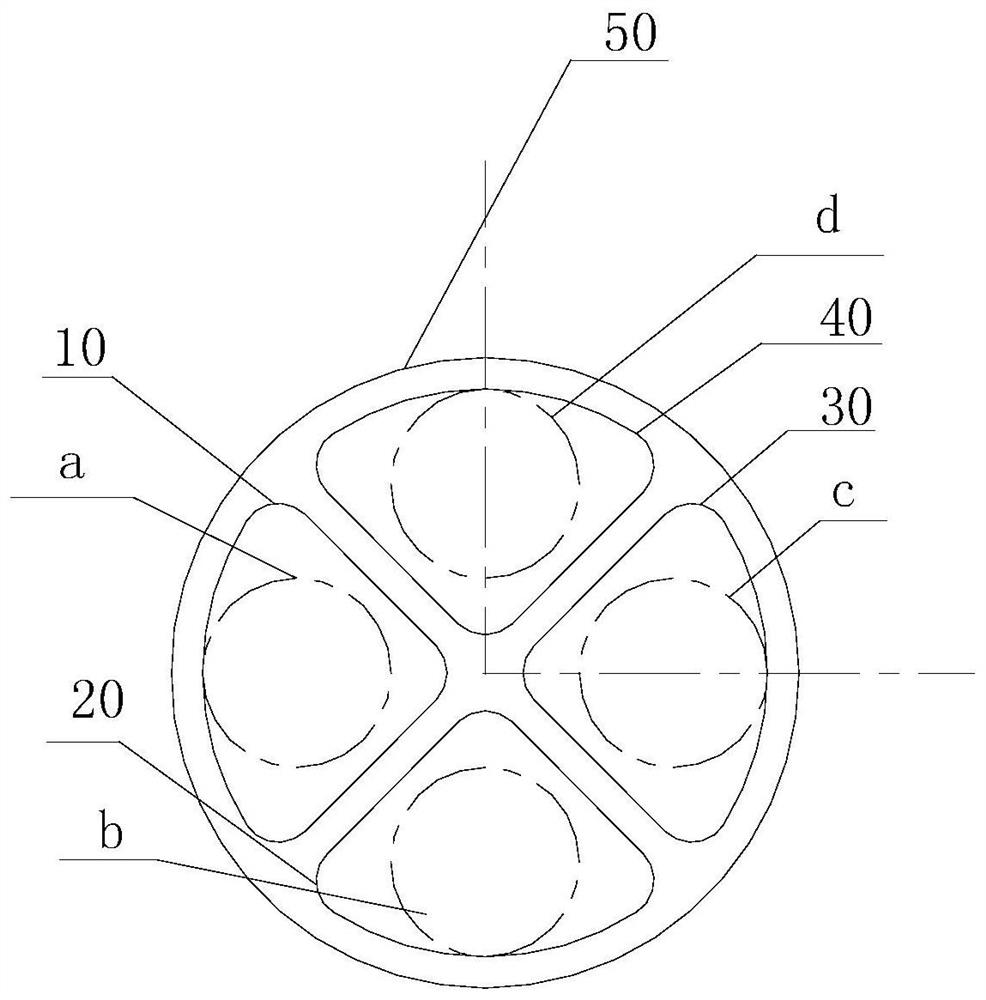

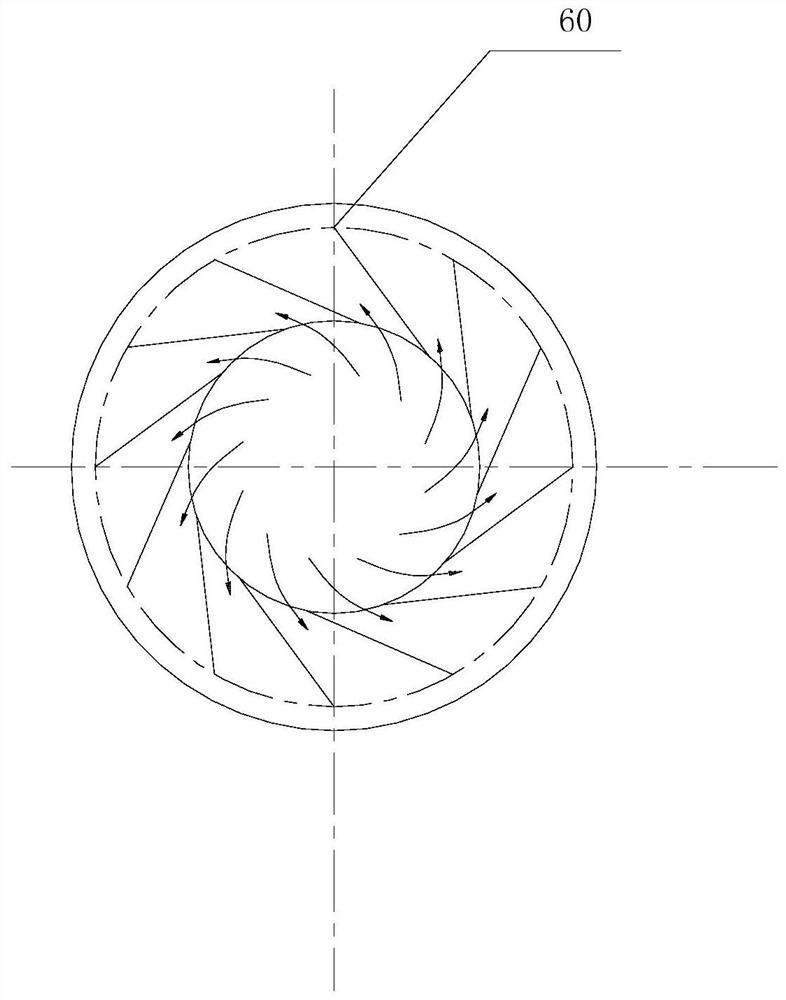

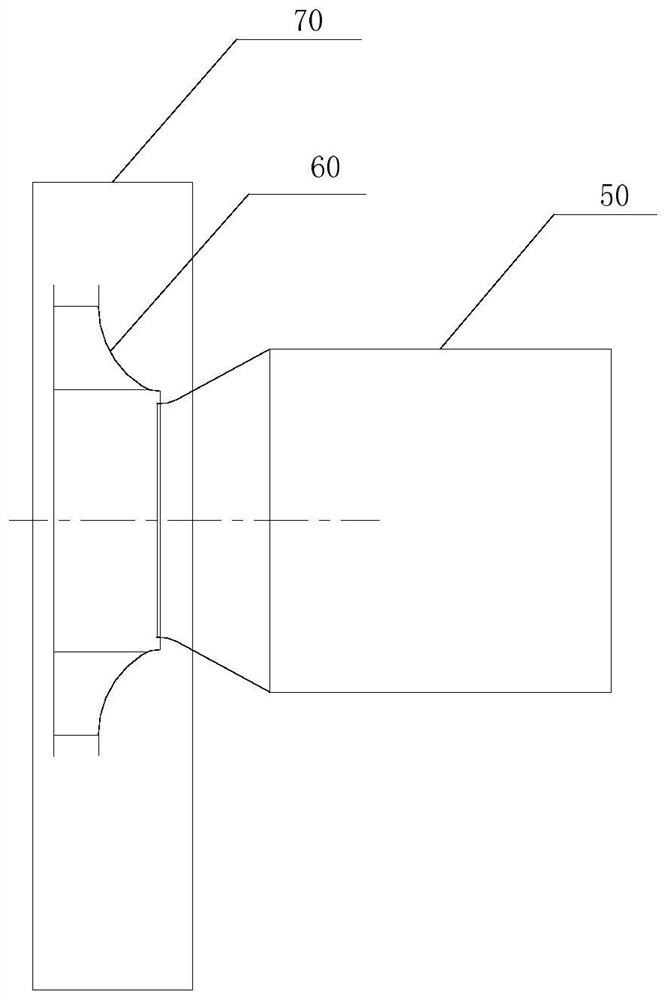

[0053] A low flow resistance pre-rotation phase muffler, comprising an outer cylinder 50 and a porous plate arranged in the outer cylinder, characterized in that: the porous plate forms a plurality of internal flow channels in the outer cylinder 50, so The sound-absorbing material is filled between the inner flow channel and the outer cylinder 50; the inlet and outlet of the inner flow channel are misaligned by one or several phases.

[0054] The wind volume is 50000m 3 / h, the pressure is 13000pa, the speed is 3000rpm, and the number of blades is 16. A low flow resistance pre-rotation phase muffler is used as an example to illustrate.

[0055] There are centrifugal impeller and volute in the centrifugal blower as the main aerodynamic components. The noise generated includes aerodynamic noise, mechanical noise and electromagnetic noise. For the blower, aerodynamic noise is the main noise source. The sound source of aerodynamic noise can be summarized as monopole source, dipol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com