Method and device for controlling flow rate of poured molten metal

A metal liquid and flow technology, which is applied to equipment supplying molten metal, metal processing equipment, manufacturing tools, etc., can solve the problems of small production volume and unstable casting quality, and achieves reduction of production volume, uniform and controllable flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

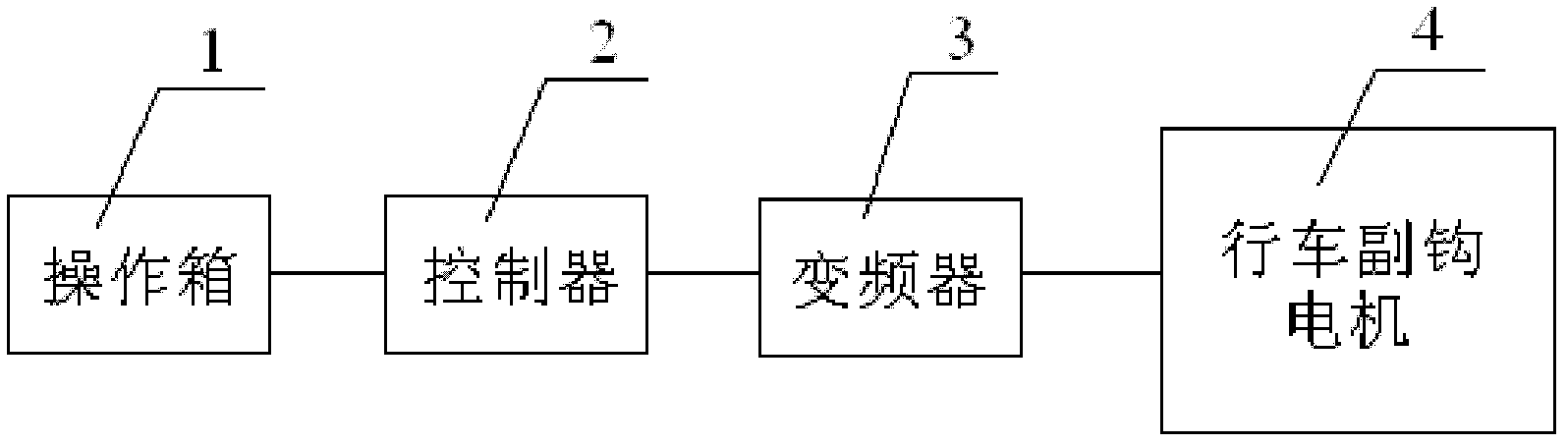

[0037] A device for controlling the pouring flow of metal liquid, its structure is as follows image 3 As shown, the device includes an operation box 1, a controller 2 and a frequency converter 3. The operation box 1, the controller 2 and the frequency converter 3 are connected by cables. 3 directly controls the motor speed, and the operation box 1 is located in the driving operation room, and can operate the auxiliary coupling motor of the driving through the controller 2 and the frequency converter 3 . The controller 2 is provided with a program for adjusting the rising speed of the auxiliary hook, and the operation of the program can make the flow of molten metal poured into the smelting furnace or the casting mold uniform and controllable. This control device is connected in parallel with the existing control device on the auxiliary hook of the vehicle, so that the two devices can be switched and used according to the process needs. The controller 2 used is a single-chip m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com