A device and method for in-situ testing the reaction behavior of refractory materials under stress

A technology for in-situ testing of refractory materials, applied in the direction of measuring devices, applying stable tension/pressure to test material strength, analyzing materials, etc., can solve the problem of inability to accurately characterize the damage behavior and mechanism of refractory materials, and cannot take into account the evolution of microstructure online access etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

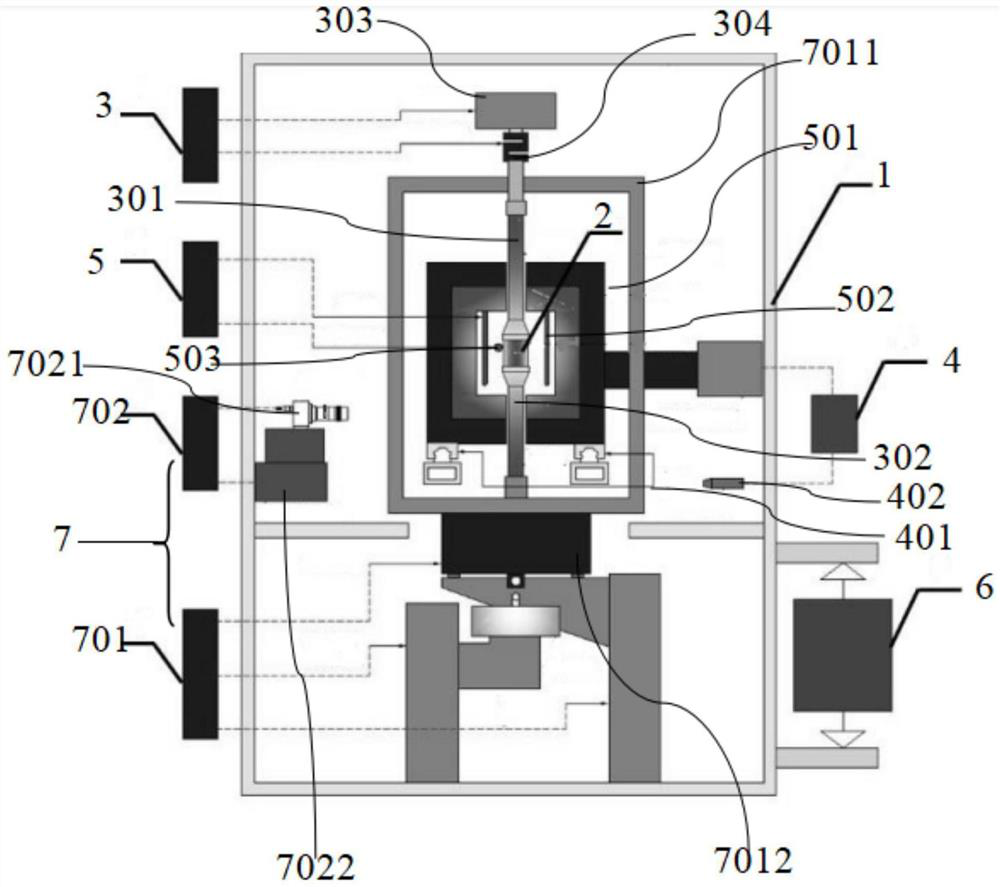

[0058] see figure 1, a device for in-situ testing the reaction behavior of refractory materials under stress, including a stress loading system 3, an air-cooled thermal shock system 4 and a heating system 5 arranged in a sealed cavity 1, and a device connected to the sealed cavity 1 The atmosphere control system 6 and the detection system 7, the stress loading system 3 is used to clamp the sample 2, and provide compressive stress loading to the sample 2 when testing the reaction behavior of the sample 2; the air-cooled thermal shock system 4 is used to test Thermal stress is provided to sample 2 during the reaction behavior of sample 2; heating system 5 surrounds sample 2 and is used to heat sample 2 when testing the reaction behavior of sample 2; atmosphere control system 6 is used to When testing the reaction behavior of the sample 2, a vacuum or a test environment with different atmospheres is provided for the sample 2; the detection system 7 is used for real-time in-situ d...

Embodiment 2

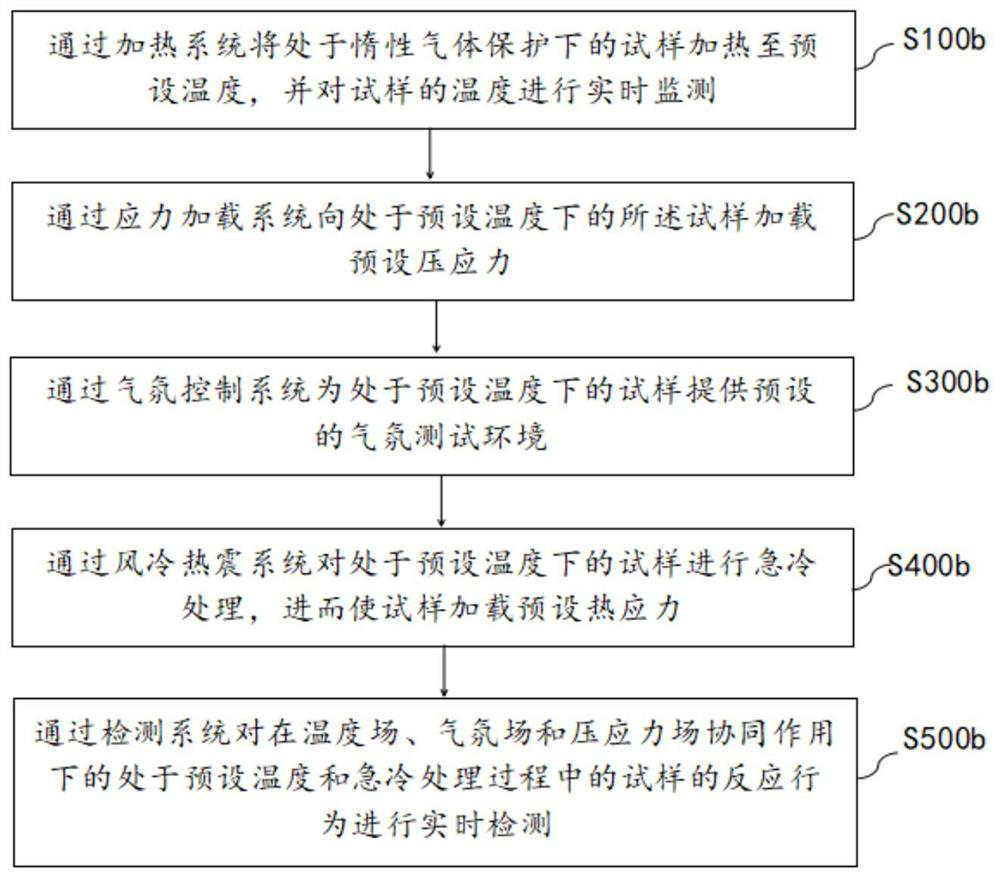

[0081] see image 3 , this embodiment provides a method for in situ testing the reaction behavior of refractory materials under stress, including:

[0082] S100b, heating the sample under the protection of the inert gas to a preset temperature through the heating system, and monitoring the temperature of the sample in real time.

[0083] Specifically, the sample is fixed between the first press bar and the second press bar, and argon gas is introduced into the furnace body through the control atmosphere control system to protect the sample with argon atmosphere, and then the heating system is controlled to raise the temperature of the heating furnace to preset temperature.

[0084] S200b. Apply a preset compressive stress to the sample at a preset temperature through a stress loading system.

[0085] Specifically, the first compression bar is controlled to move in the vertical direction through the loading mechanism, so as to realize the adjustment of the compressive stress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com