System and method for evaluating reaction behavior of non-oxide materials under complex stress

A non-oxide, complex stress technology, applied in the analysis of materials, the use of stable tension / pressure test material strength, instruments, etc., can solve the cognition of the cause of unfavorable material damage and the prediction of service life, non-oxide materials At the same time, precise control and inability to effectively simulate the high-temperature interface behavior of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

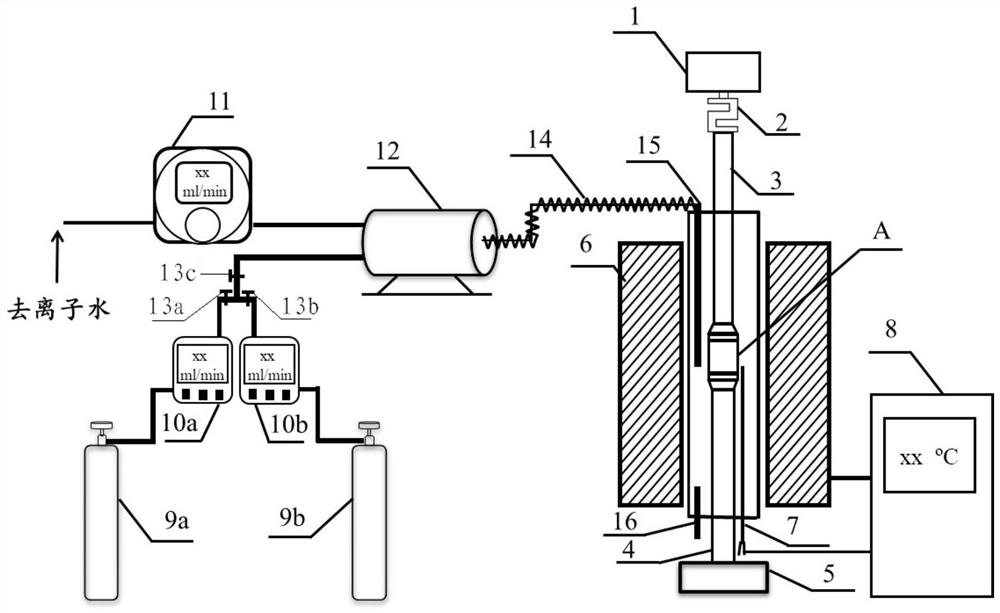

[0026] see figure 1 , a system for evaluating the reaction behavior of non-oxide materials under complex stress provided by an embodiment of the present invention, including

[0027] Stress control device: installed on the non-oxide material sample A, for providing a stress field to the sample A when evaluating the reaction behavior of the sample A;

[0028] Temperature control device: installed on the non-oxide material sample A, for providing a temperature field to the sample A when evaluating the reaction behavior of the sample A;

[0029] Atmosphere control device: installed on the non-oxide material sample A, for providing an atmosphere field to the sample A when evaluating the reaction behavior of the sample A.

[0030] Wherein, the stress control device includes an upper pressing bar 3 and a lower pressing bar 4 arranged at the upper and lower ends of the sample A, a stress loader 1 connected to the upper pressing bar 3 for applying pressure to the sample A through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com