Dry chemical detection test paper and preparation process

A technology for detecting test paper and preparation process, which is applied in the field of dry chemical detection, and can solve problems such as complex overall structure and complex production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

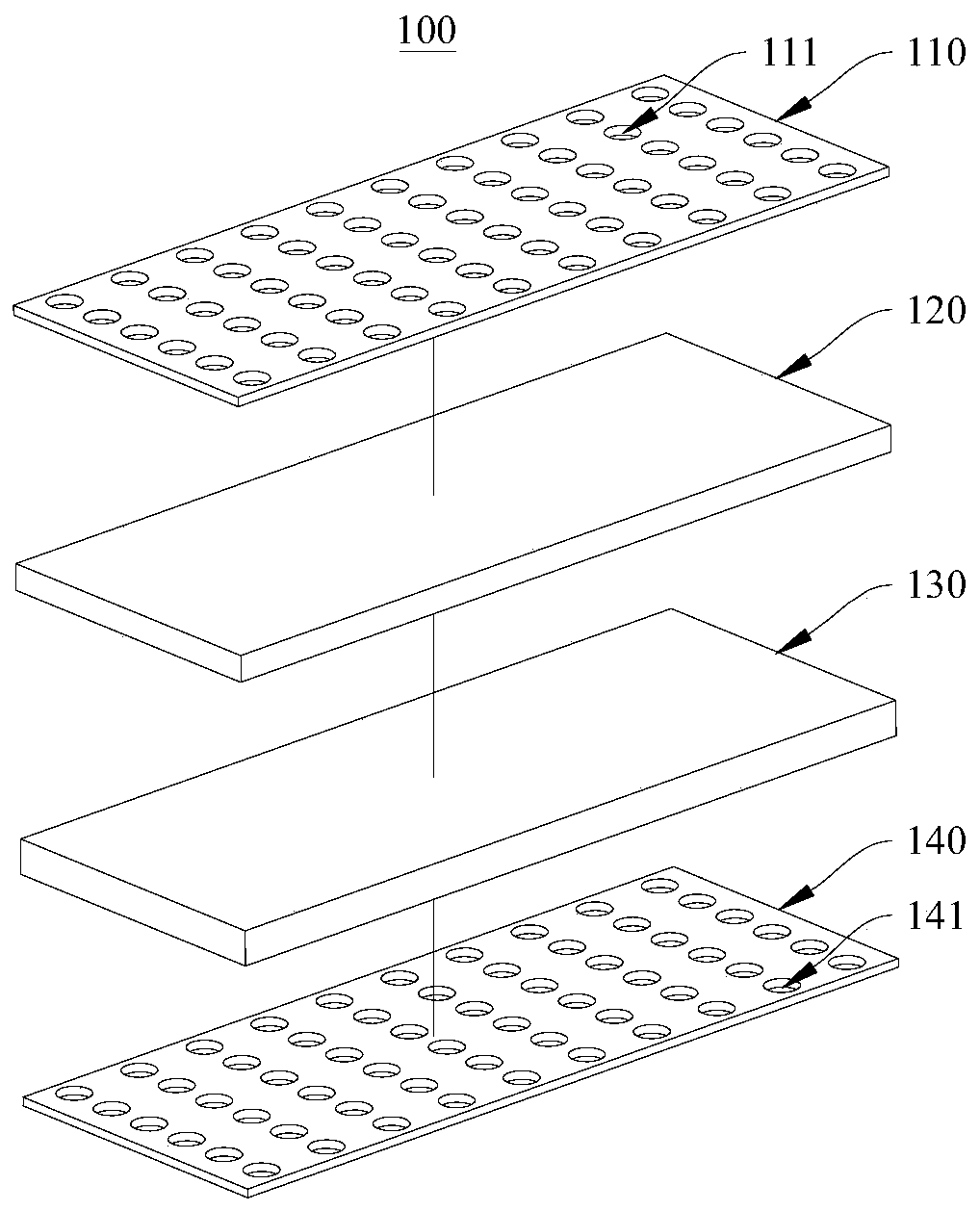

[0044] See figure 1 , a kind of dry chemical detection test paper 100 provided in this embodiment, it comprises and stacks up together longitudinally: upper substrate 110, middle layer and lower substrate 140, and upper substrate 110 is provided with a plurality of sampling holes 111 that are arranged at intervals . Usually, the middle layer includes one functional layer or more than two functional layers stacked together longitudinally. In this embodiment, the middle layer includes a blood filter layer 120 stacked longitudinally together for filtering blood cells. In some other embodiments, the intermediate layer is only the reactive layer 130, or according to actual needs, the intermediate layer may also include other functional layers. Each functional layer of the intermediate layer is a porous material film, and the pores in the barrier area are irreversibly closed. Each functional layer of the intermediate layer includes multiple detection areas and corresponding barrier...

no. 2 example

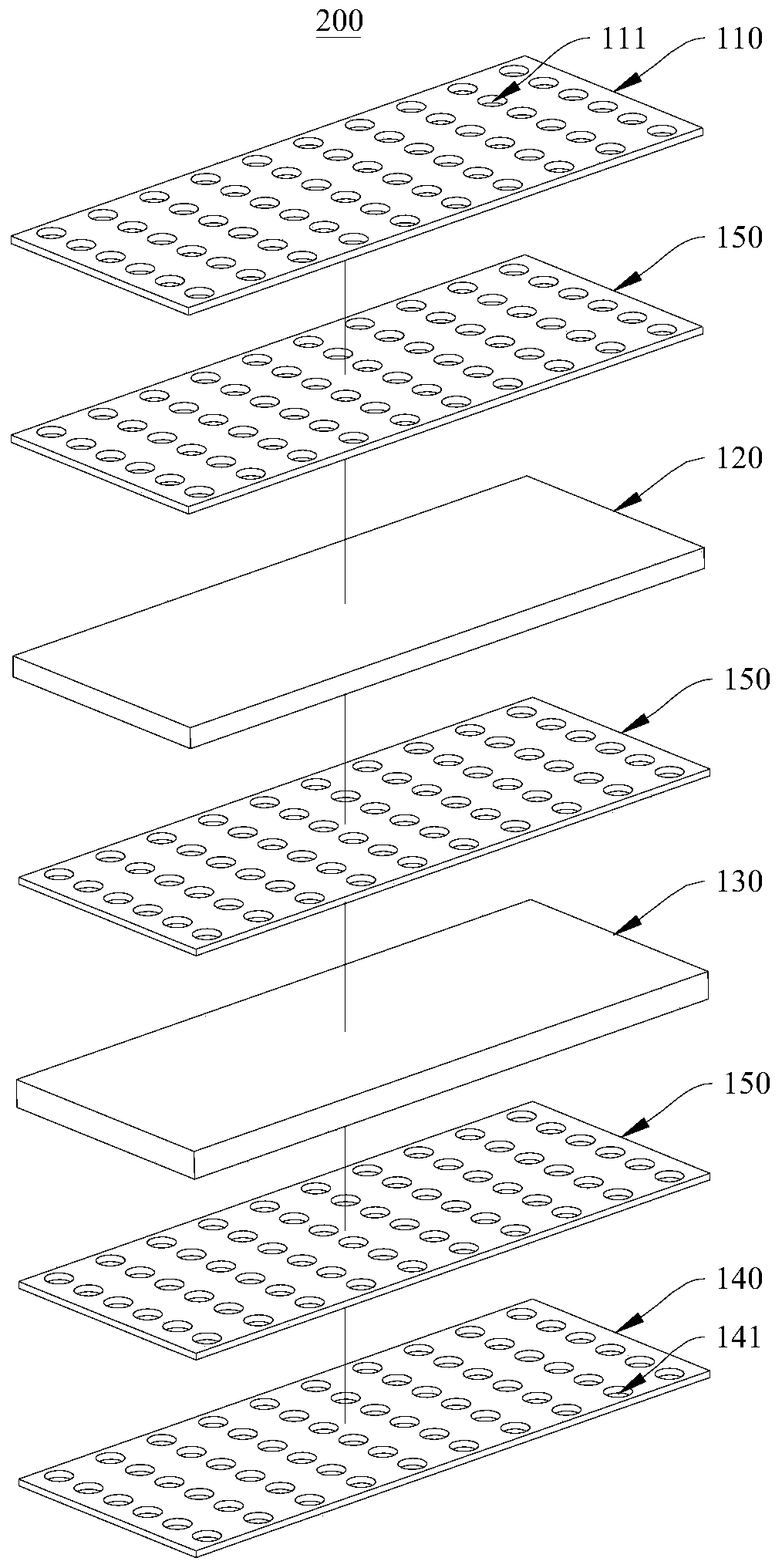

[0054] See figure 2, the present embodiment provides a dry chemical detection test paper 200, which includes sequentially stacked longitudinally: an upper substrate 110, an ink printing layer 150, a blood filter layer 120, an ink printing layer 150, a reaction layer 130, and an ink printing layer 150 ( can be omitted) and the lower substrate 140. The upper substrate 110 is provided with a plurality of sampling holes 111 arranged at intervals; the blood filter layer 120 and the reaction layer 130 are both porous material membranes, and are divided into a plurality of detection areas corresponding to the sampling holes 111 one-to-one, and surrounding each In the barrier area on the periphery of the detection area, the ink printing layer 150 is only arranged on the surface of the barrier area of the blood filter layer 120 or the reaction layer 130, and is usually formed by printing ink on the surface of the barrier area of the blood filter layer 120 or the reaction layer 130...

no. 3 example

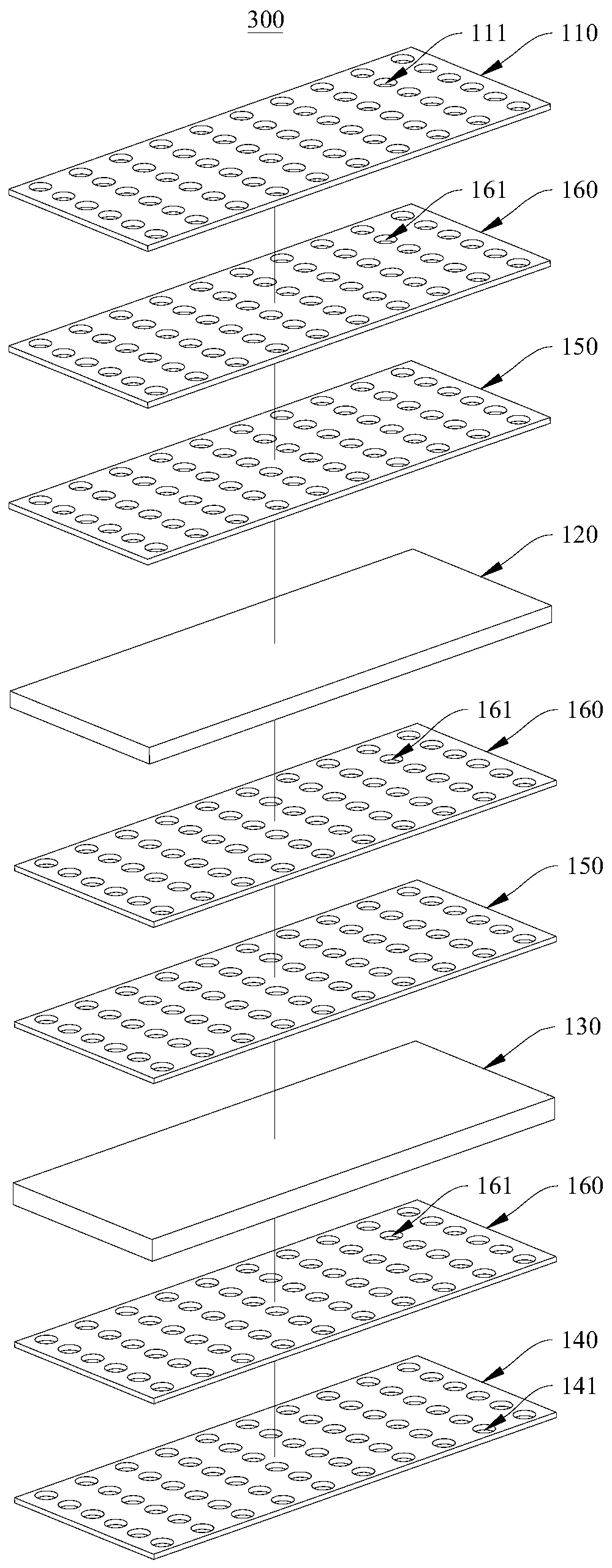

[0059] See image 3 , the present embodiment provides a dry chemical detection test paper 300, which includes sequentially laminated together from top to bottom: upper substrate 110, hot melt adhesive layer 160, ink printing layer 150, blood filter layer 120, hot melt adhesive layer 160 , ink printing layer 150 , reaction layer 130 , hot melt adhesive layer 160 and lower substrate 140 . Among them, the upper substrate 110 is provided with a plurality of sampling holes 111 arranged at intervals; the blood filter layer 120 and the reaction layer 130 are both porous material films, which are divided into a plurality of detection areas corresponding to the sampling holes 111 one by one, and surrounded by In the barrier area on the periphery of each detection area, the ink printing layer 150 is only arranged on the surface of the barrier area of the adjacent blood filtering layer 120 or the reaction layer 130, and part of the ink of the ink printing layer 150 is filled into the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com