Numerical control machine tool running state monitoring method based on Spark

A technology of CNC machine tools and running status, which is applied in the direction of program control, computer control, computer parts and other directions, can solve the problems of waste of data resources, low efficiency, and failure to warn maintenance personnel in advance, and achieve the goal of reducing research and development costs and high throughput Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

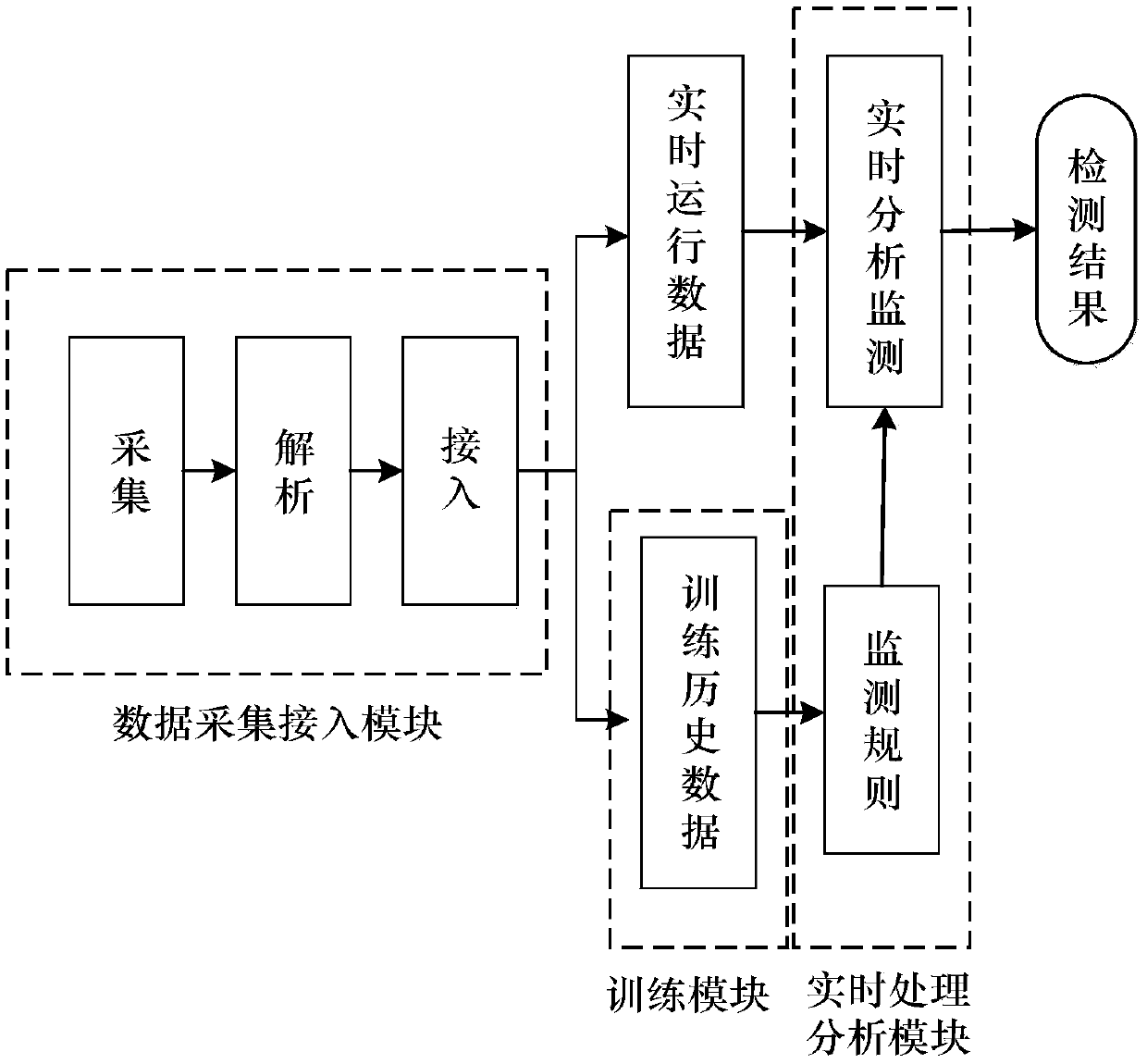

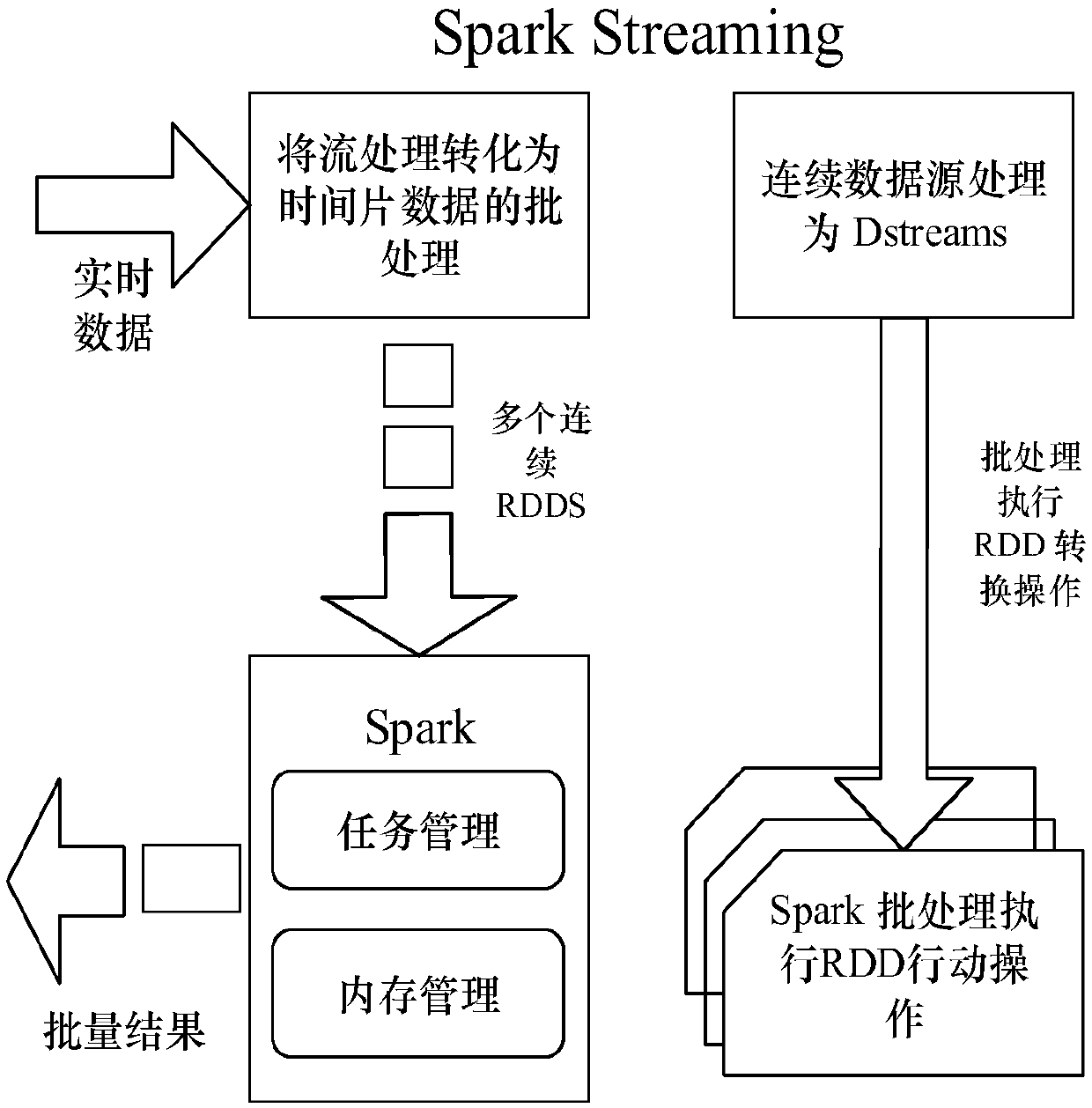

[0034] Such as Figure 1 ~ Figure 2 As shown, a Spark-based CNC machine tool running status monitoring system includes the following steps:

[0035] Step 1: The collection of status data information of CNC machine tools includes two methods. The first method is to use the development interface provided by the CNC manufacturer, and the other is to obtain the running status data of CNC machine tools through the OPC protocol;

[0036] Step 2: Then use the z-score normalization method to normalize the original sample parameters;

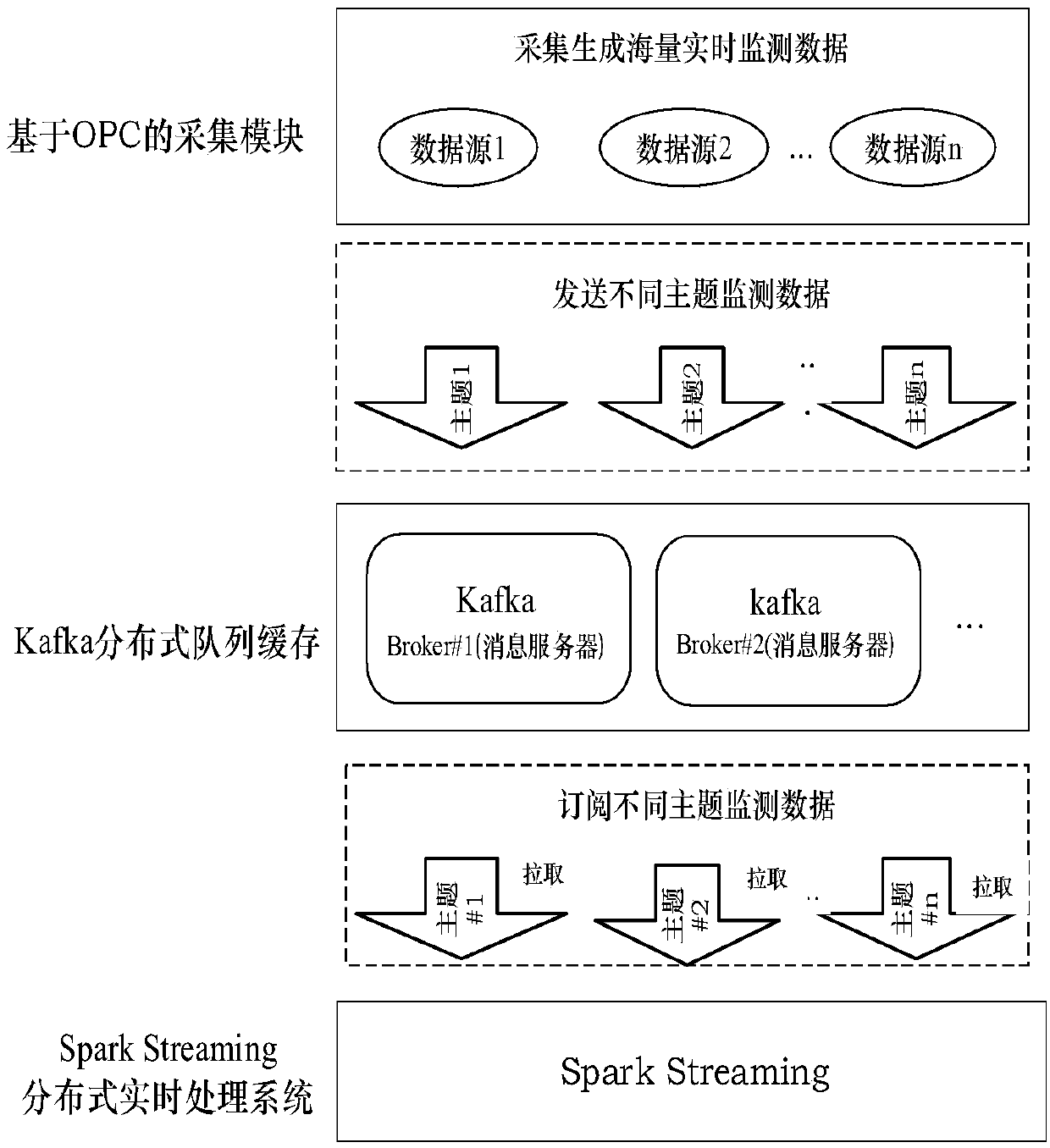

[0037] Step 3: Realize access to state data by introducing Kafka, a distributed message queue. By adding data to the Topic field, the integrated sending of different types of status data is realized. That is, messages within the same topic are partitioned to different servers according to a certain algorithm. When pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com