Full-die-cutting ultrahigh-frequency electronic tag antenna and processing equipment and processing technology thereof

An electronic label, ultra-high frequency technology, applied in the field of ultra-high frequency electronic label antenna and its processing equipment and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

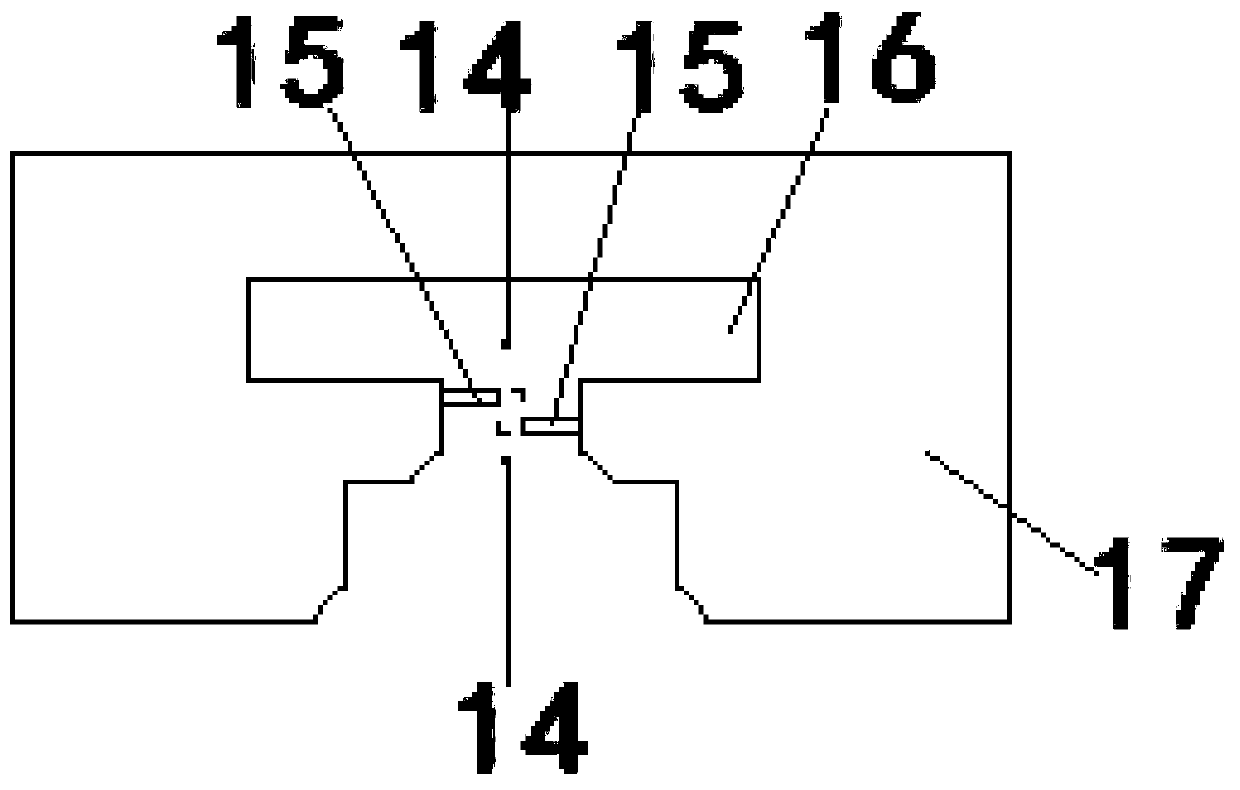

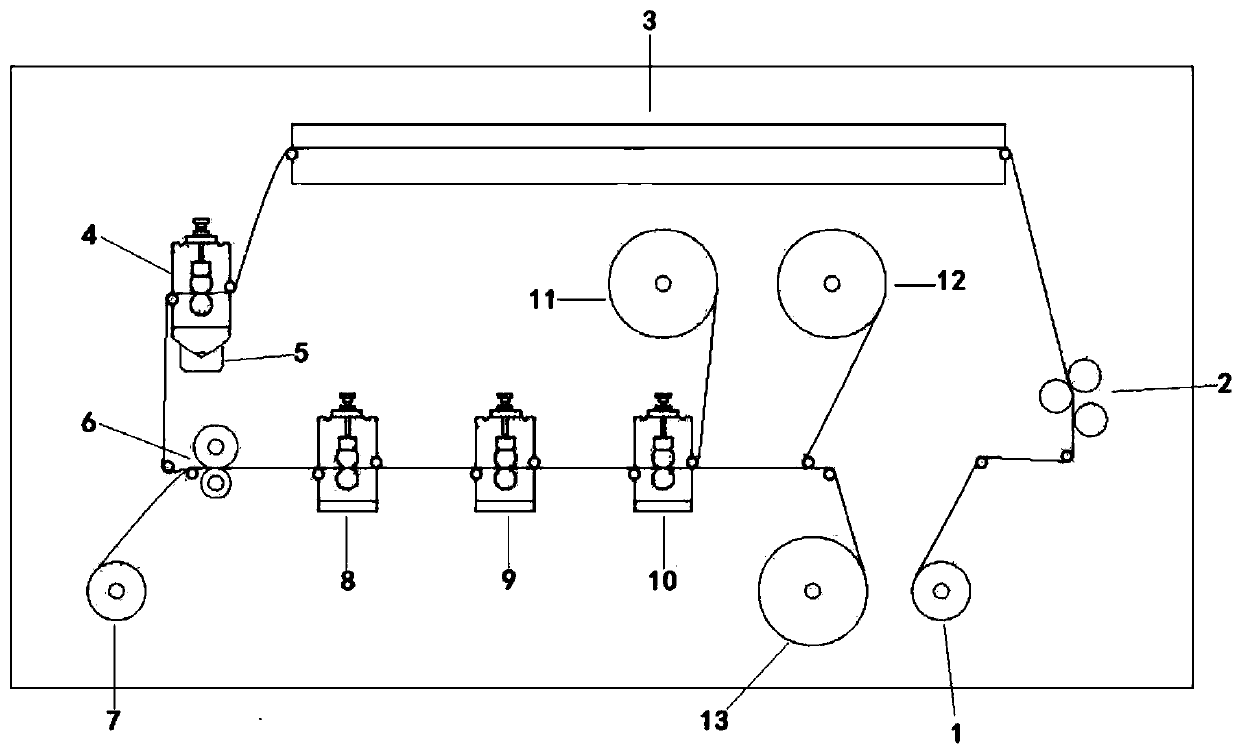

[0095] Specific embodiment 2, specific embodiment 2 is basically the same as this embodiment 1, the difference is: The mechanism is a die-cutting machine that performs flat die-cutting and / or round-knife die-cutting on the chip binding points 15 and the chip binding positioning points 14 at the same time, that is to say, the first die-cutting mechanism completes the chip binding points 15 and 14 at one time. The flat die-cutting and / or the circular knife die-cutting of the chip binding positioning point 14, for example, all the flat die-cutting machines are replaced by the circular knife die-cutting machines. Similar operations are performed to form the antenna layer by one-time flat die-cutting. The chip binding point 15 and the chip binding positioning point 14, that is to say, the die-cutting tool of the flat die-cutting machine will die-cut the chip binding point 15 and the chip binding positioning point 14 on the antenna layer at one time, for example The blade thickness ...

specific Embodiment 3

[0098] The specific embodiment 3, the specific embodiment 3 is basically the same as the present embodiment 1, the difference is: in the production step 5 of the processing technology of the fully die-cut UHF electronic tag antenna in the specific embodiment 3, the The first die-cutting mechanism for die-cutting the chip binding positioning points 14 and the chip binding points 15 and the second die-cutting mechanism 10 for die-cutting the surrounding edges of the antenna body 17 are combined into a flat die-cutting machine or a circular knife die cutting machine.

[0099] That is to say, the first die-cutting mechanism and the second die-cutting mechanism 10 are combined into a flat die-cutting machine or a circular knife die-cutting machine, which can complete the flat die of the chip binding point 15 and the chip binding positioning point 14 at one time. The operation of cutting and / or die-cutting with a circular knife and performing flat die-cutting and / or die-cutting with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com