Anti-steel-seepage furnace floor structure

A furnace bottom structure and furnace bottom technology, applied in the direction of manufacturing converters, etc., can solve the problems of steel infiltration, backward movement of working layer bricks, etc., to achieve the effect of high density, avoid triangular packing area, and avoid backward movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

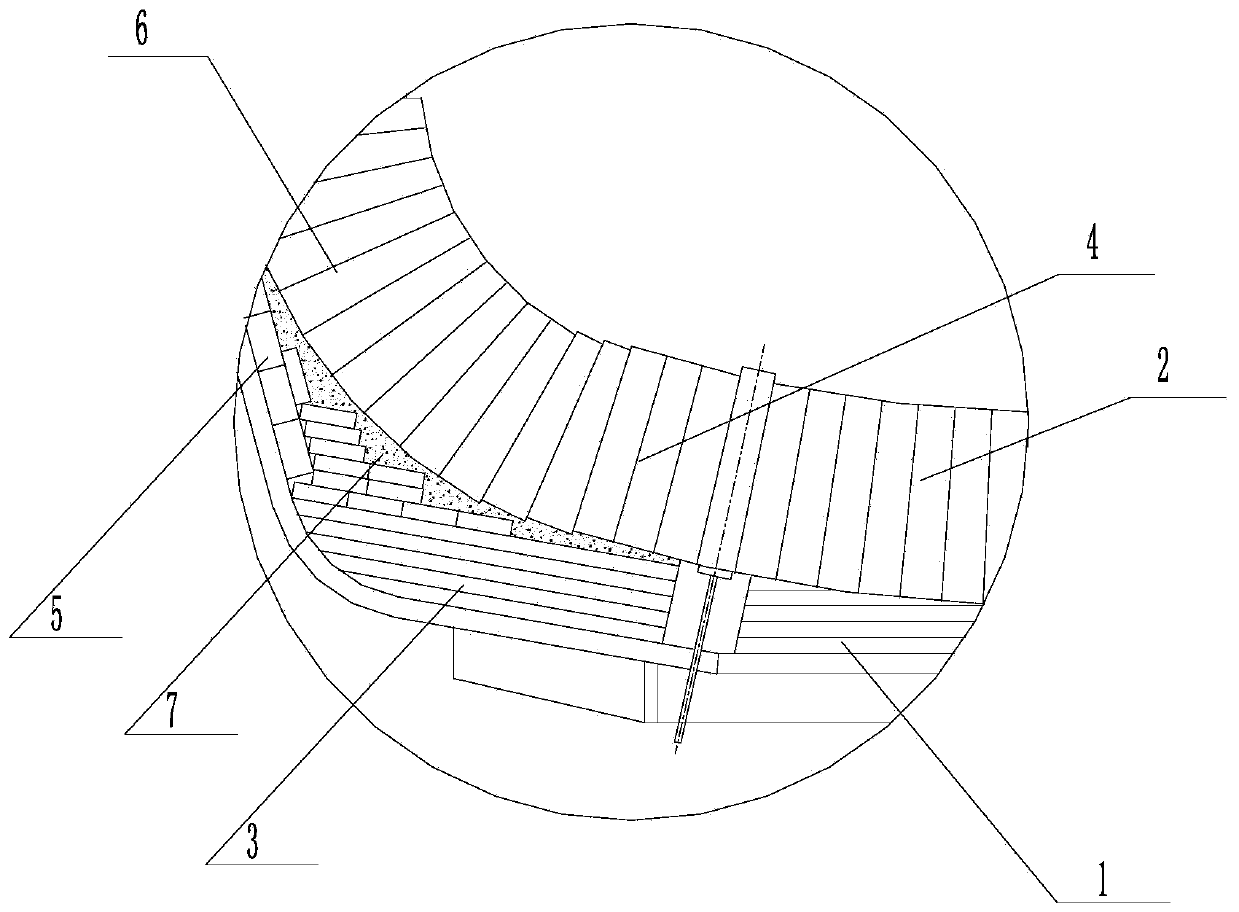

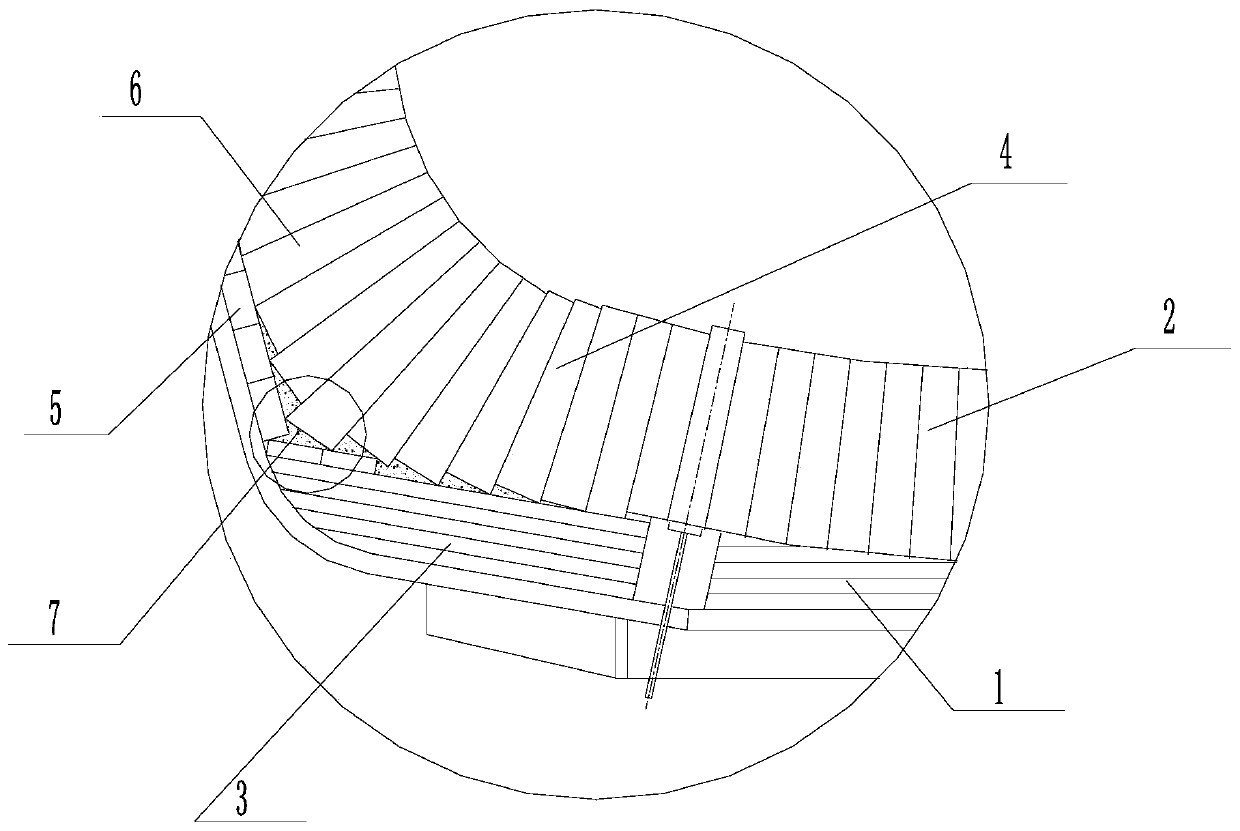

[0016] Such as figure 2 The converter bottom structure of anti-seepage steel shown is composed of furnace bottom area I, furnace bottom arc transition area II, and molten pool transition area III; the furnace bottom area I, furnace bottom arc transition area II, The molten pool transition zone III is equipped with the lower permanent layer lining and the upper working layer lining, which are the permanent layer lining 1 in the furnace bottom area, the working layer lining 2 in the furnace bottom area, the permanent layer lining 3 in the arc-shaped transition area of the furnace bottom, and the furnace lining. The working layer lining 4 in the bottom arc transition area, the permanent layer lining 5 in the molten pool transition area, and the working layer lining 6 in the molten pool transition area; the permanent layer lining 3 in the molten pool transition area; the working layer lining 6 in the molten pool transition area is closely built on the permanent layer lining 5 i...

Embodiment 2

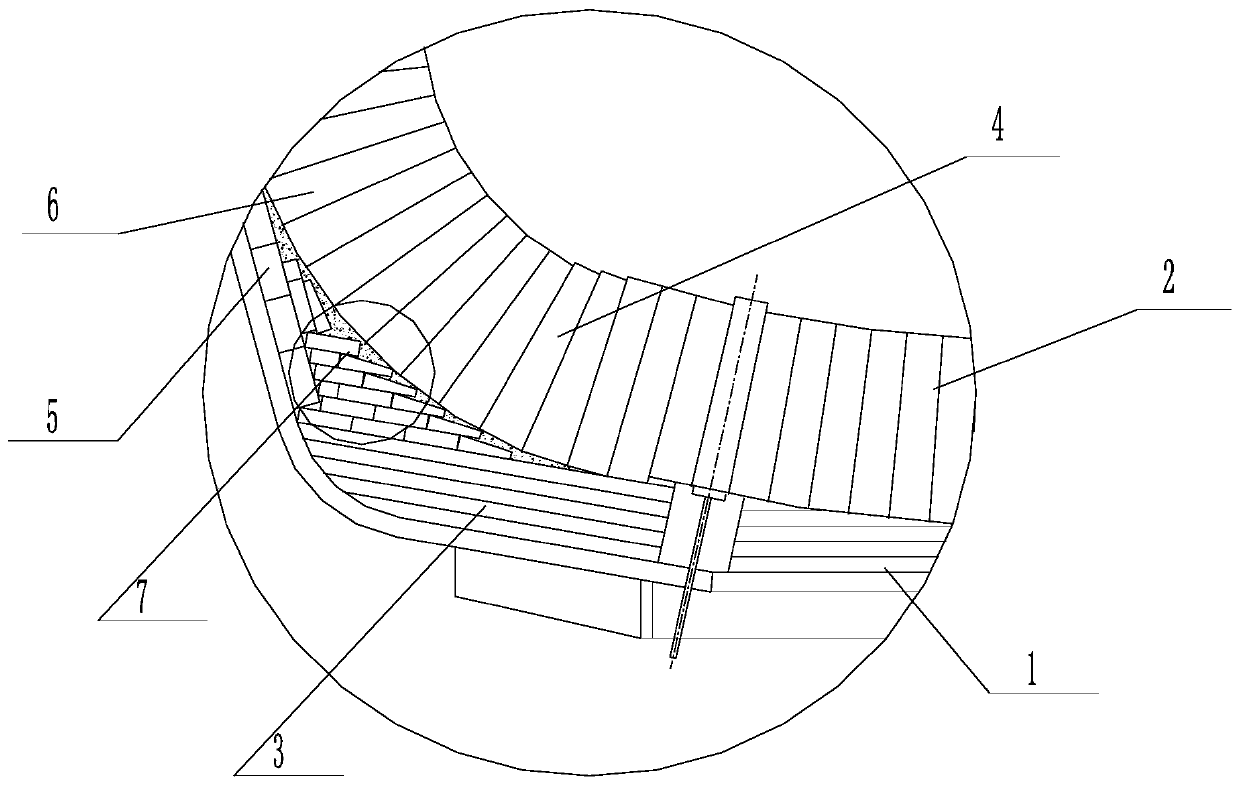

[0019] Such as image 3 The converter bottom structure of anti-seepage steel shown is composed of furnace bottom area I, furnace bottom arc transition area II, and molten pool transition area III; the furnace bottom area I, furnace bottom arc transition area II, The molten pool transition zone III is equipped with the lower permanent layer lining and the upper working layer lining, which are the permanent layer lining 1 in the furnace bottom area, the working layer lining 2 in the furnace bottom area, the permanent layer lining 3 in the arc-shaped transition area of the furnace bottom, and the furnace lining. The working layer lining 4 in the bottom arc transition area, the permanent layer lining 5 in the molten pool transition area, and the working layer lining 6 in the molten pool transition area; the permanent layer lining 3 in the molten pool transition area; the working layer lining 6 in the molten pool transition area is closely built on the permanent layer lining 5 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com