Preparation method of wrinkled fabric

A fabric and raw material technology, applied in the field of textile fabrics, can solve the problems of elastic chiffon product quality and complex processing process, and achieve the effects of avoiding strong twisting process, durable and stable elasticity, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preparation method of wrinkled fabric, the steps are as follows:

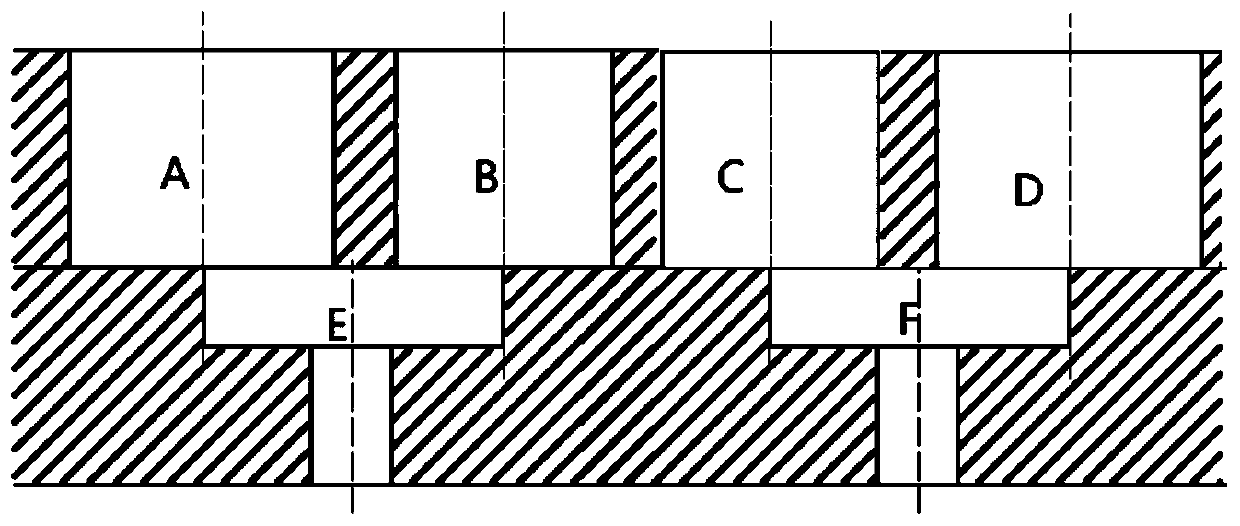

[0051] (1) Preparation of crescent-shaped composite fiber: PET (intrinsic viscosity is 0.53dL / g) and PTT (intrinsic viscosity is 1.2dL / g) with a mass ratio of 50:50 are juxtaposed by FDY process and circular composite fiber (will The spinneret holes on the spinneret are changed from circular to crescent-shaped) to prepare crescent-shaped composite fibers; wherein, when preparing side-by-side composite fibers, PET melt and PTT melt are distributed from the same spinneret The spinneret m (crescent spinneret) and spinneret n (crescent spinneret) on the top are extruded;

[0052] The distribution refers to distributing the PTT melt through the distribution hole A, while distributing the PET melt through the distribution hole B to the spinneret m, distributing the PTT melt through the distribution hole C, and simultaneously distributing the PET melt through the distribution hole D To the spinneret hole n; ...

Embodiment 2

[0067] A preparation method of wrinkled fabric, the steps are as follows:

[0068] (1) Preparation of crescent-shaped composite fiber: PET (intrinsic viscosity is 0.52dL / g) and PTT (intrinsic viscosity is 1.1dL / g) with a mass ratio of 50:50 are juxtaposed by FDY process and circular composite fiber (will be The spinneret holes on the spinneret are changed from circular to crescent-shaped) to prepare crescent-shaped composite fibers; wherein, when preparing side-by-side composite fibers, PET melt and PTT melt are distributed from the same spinneret The spinneret m (crescent spinneret) and spinneret n (crescent spinneret) on the top are extruded;

[0069] The distribution refers to distributing the PTT melt through the distribution hole A, while distributing the PET melt through the distribution hole B to the spinneret m, distributing the PTT melt through the distribution hole C, and simultaneously distributing the PET melt through the distribution hole D To the spinneret hole ...

Embodiment 3

[0084] A preparation method of wrinkled fabric, the steps are as follows:

[0085] (1) Preparation of crescent-shaped composite fiber: PET (intrinsic viscosity is 0.56dL / g) and PTT (intrinsic viscosity is 1.11dL / g) with a mass ratio of 50:50 are juxtaposed by FDY process and circular composite fiber (will The spinneret holes on the spinneret are changed from circular to crescent-shaped) to prepare crescent-shaped composite fibers; wherein, when preparing side-by-side composite fibers, PET melt and PTT melt are distributed from the same spinneret The spinneret m (crescent spinneret) and spinneret n (crescent spinneret) on the top are extruded;

[0086] The distribution refers to distributing the PTT melt through the distribution hole A, while distributing the PET melt through the distribution hole B to the spinneret m, distributing the PTT melt through the distribution hole C, and simultaneously distributing the PET melt through the distribution hole D To the spinneret hole n;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com