Multi-cutter disc large-section vertical shaft tunneling device

A large-section, multi-cutter technology, used in shaft equipment, well sinking, mining equipment, etc., can solve problems such as equipment shortage and backward construction methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

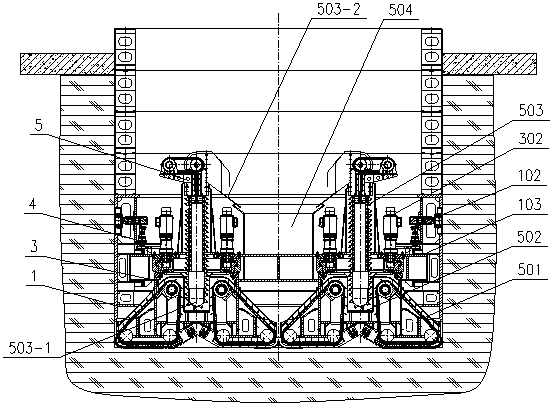

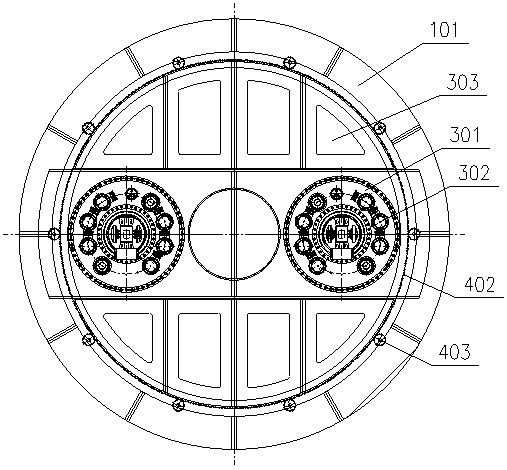

[0022] Embodiment 1: as figure 1 As shown, a multi-cutter large-section shaft excavation device includes a shield body 1. The shield body 1 is composed of several shield body block units 101 fixedly connected. An excavation device is arranged under the shield body 1. The shield body 1 A rotating track 103 is arranged on the top, and the small-circle turning device 3 is movably arranged on the turning track 103. The small-circle turning device 3 is connected with the large-circle turning drive device 4 and the excavation device respectively, and the large-circle turning drive device 4 is connected with the shield body 1. Fixed connection; the shield body 1 is provided with a main machine slag discharge device 5, which is a mechanical slag discharge device, and the main machine slag discharge device 5 is connected with the excavation device and the small circle slewing device 3 respectively.

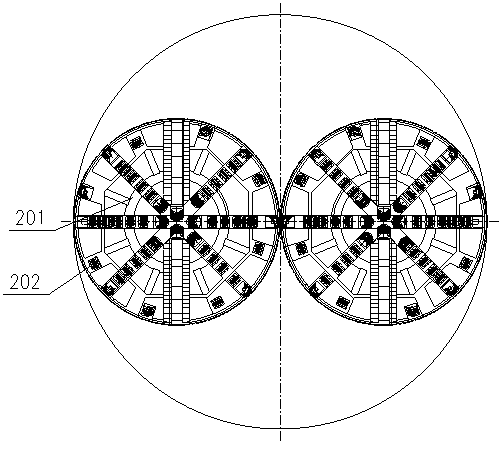

[0023] Such as image 3 As shown, the excavation device includes several cutterheads ...

Embodiment 2

[0029] Embodiment 2: Multi-cutter large-section vertical shaft excavation device, when the main machine slag discharging device 5 is a fluid slagging device, the mud pumping device in the fluid slagging mode is used to collect the first stage of the main machine slagging device 5 The slag device 501, the primary slag collection cylinder 502, the vertical lifting device 503 and the secondary slag collection cylinder 504 are removed, the mud pump is installed, the mud water pipeline is connected, the cutter head is excavated in the mud water, and the principle of mud water pumping is used. The mud carries the dregs out of the well, and through the separation of mud and water, the separation of the dregs and the circulation of the mud are completed.

[0030] All the other structures are the same as in Example 1.

Embodiment 3

[0031] Embodiment 3: Multi-cutter large-section shaft excavation device, when the main machine slag discharging device 5 adopts a fluid slagging device, the vacuum pumping device in the fluid slagging mode is used to collect the first-stage slag in the main machine slagging device 5 The device 501, the primary slag collection cylinder 502, the vertical lifting device 503 and the secondary slag collection cylinder 504 are removed, a vacuum pump is installed, and relevant pipelines are connected. The slag is transported to the outside of the well to complete the slag discharge operation.

[0032] All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com