Oiling device for installing automobile switch

A technology for installation and switching, which is applied in the sealing of vehicle parts, transportation and packaging, and engines, etc. It can solve problems such as lubricant oil leakage, achieve good sealing effect, firm connection structure, and convenient fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

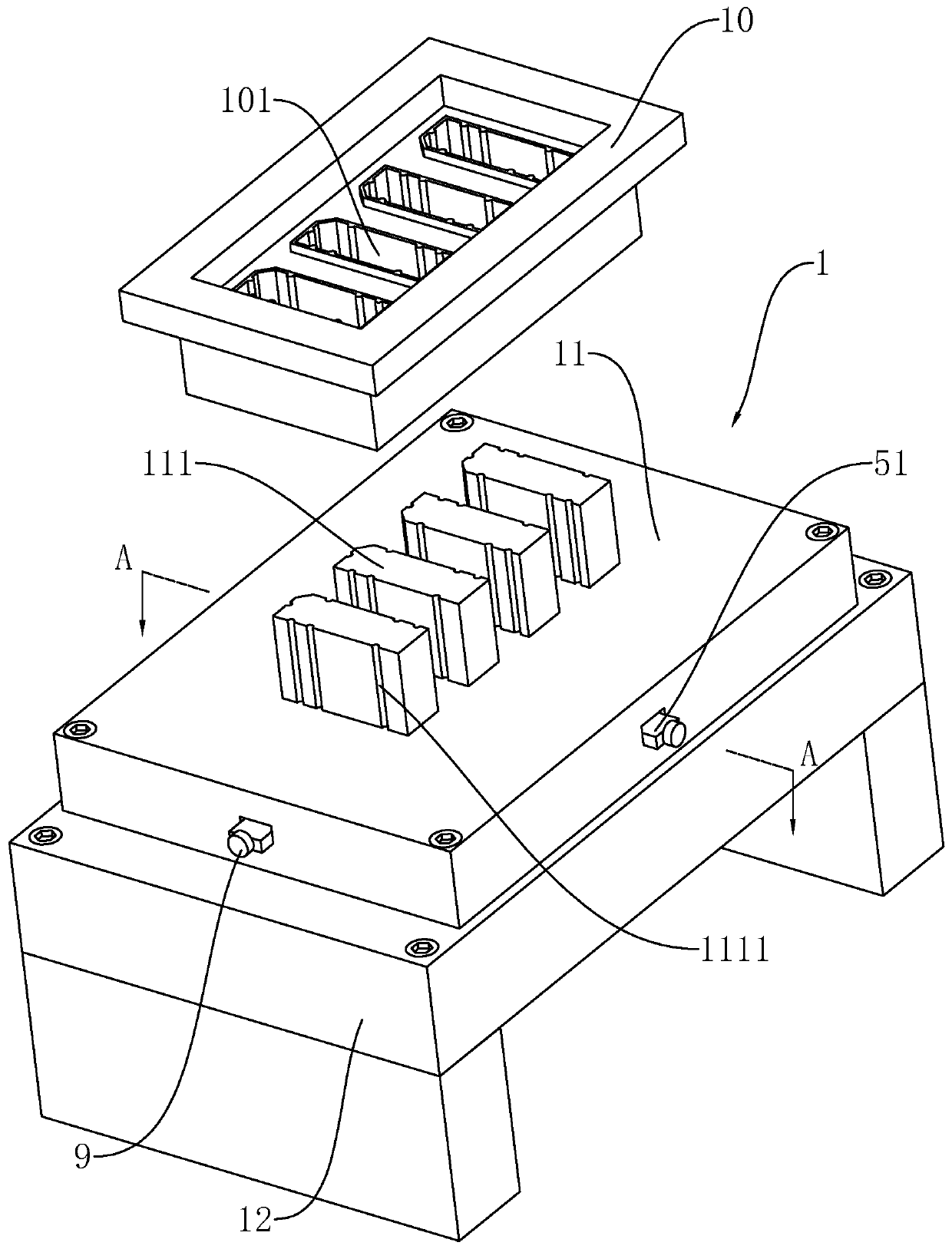

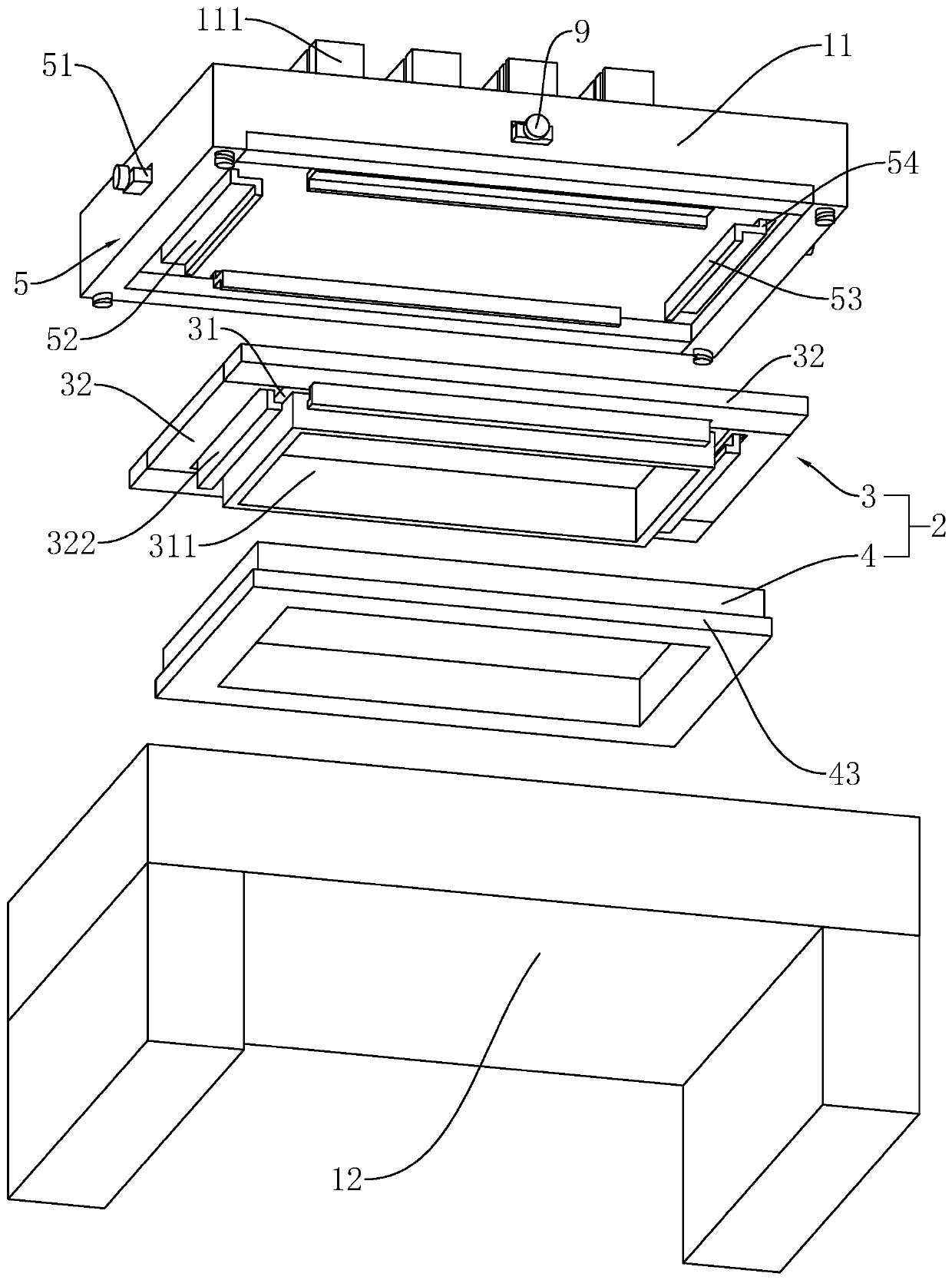

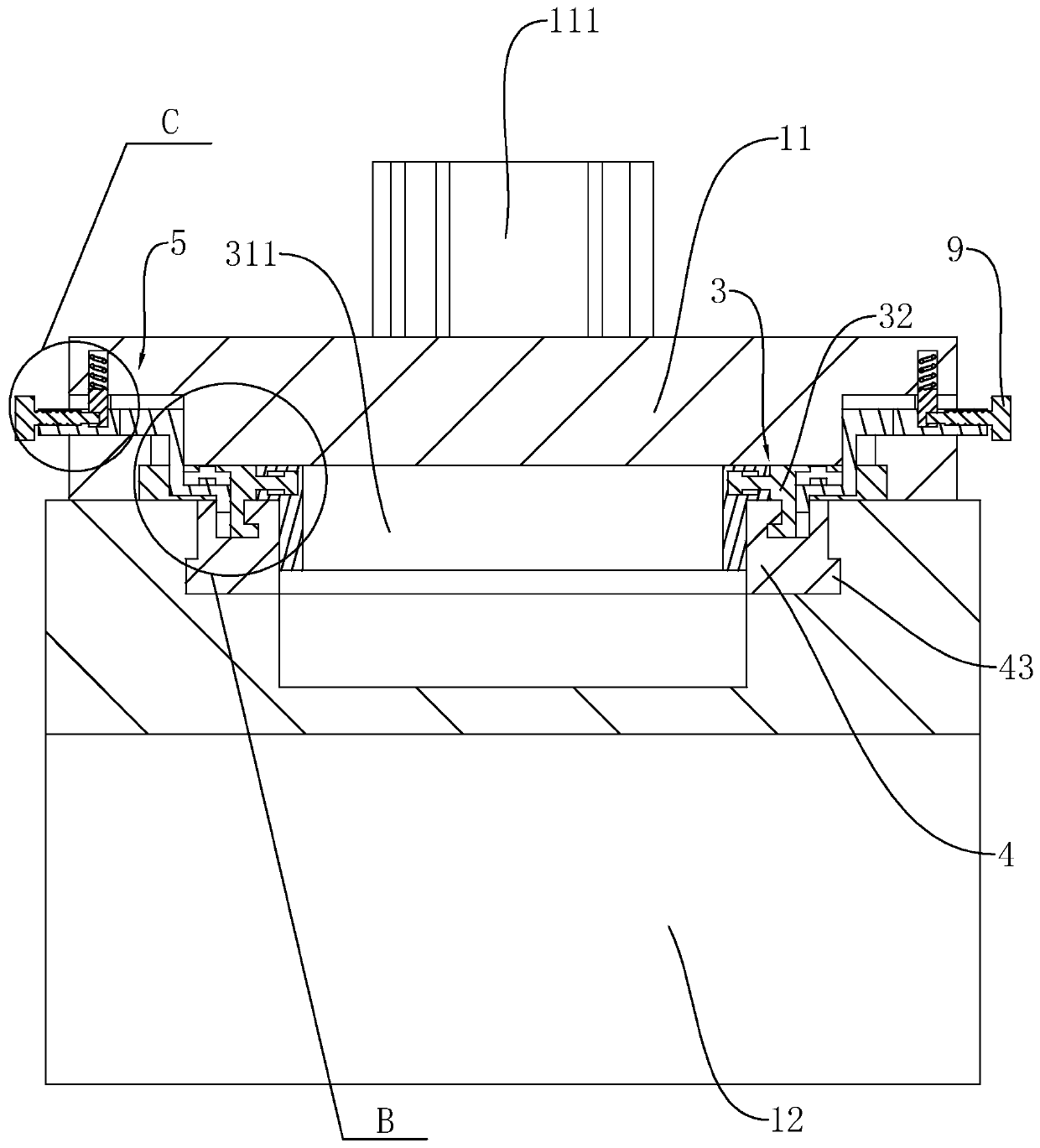

[0039] An oiling device for automotive switch installation, such as figure 1 As shown, an oiling tool 1 is included, and the oiling tool 1 includes an upper cover layer 11 and a bottom layer 12, and the four corners of the upper cover layer 11 and the bottom layer 12 are fixed by bolts.

[0040] Such as figure 1 , 2 As shown, the bottom layer 12 and the upper cover layer 11 are connected through the sealing mechanism 2, which not only maintains the connection between the upper cover layer 11 and the bottom layer 12, but also improves the sealing performance of the upper cover layer 11 and the bottom layer 12.

[0041] Such as figure 1 As shown, the upper cover layer 11 is fixed with oiling seats 111 at intervals, and the side walls of the oiling seats 111 are spaced apart and provided with several oil inlet passages 1111 extending in the vertical direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com