Combustion chamber structure

A combustion chamber, gas technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the difficulty in meeting the requirements of flow resistance and flame stability, increased friction loss between air flow and cylinder wall, and the structural length of the combustion chamber Increase and other problems, to achieve the effect of improving mixing uniformity, improving flame stability, and shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

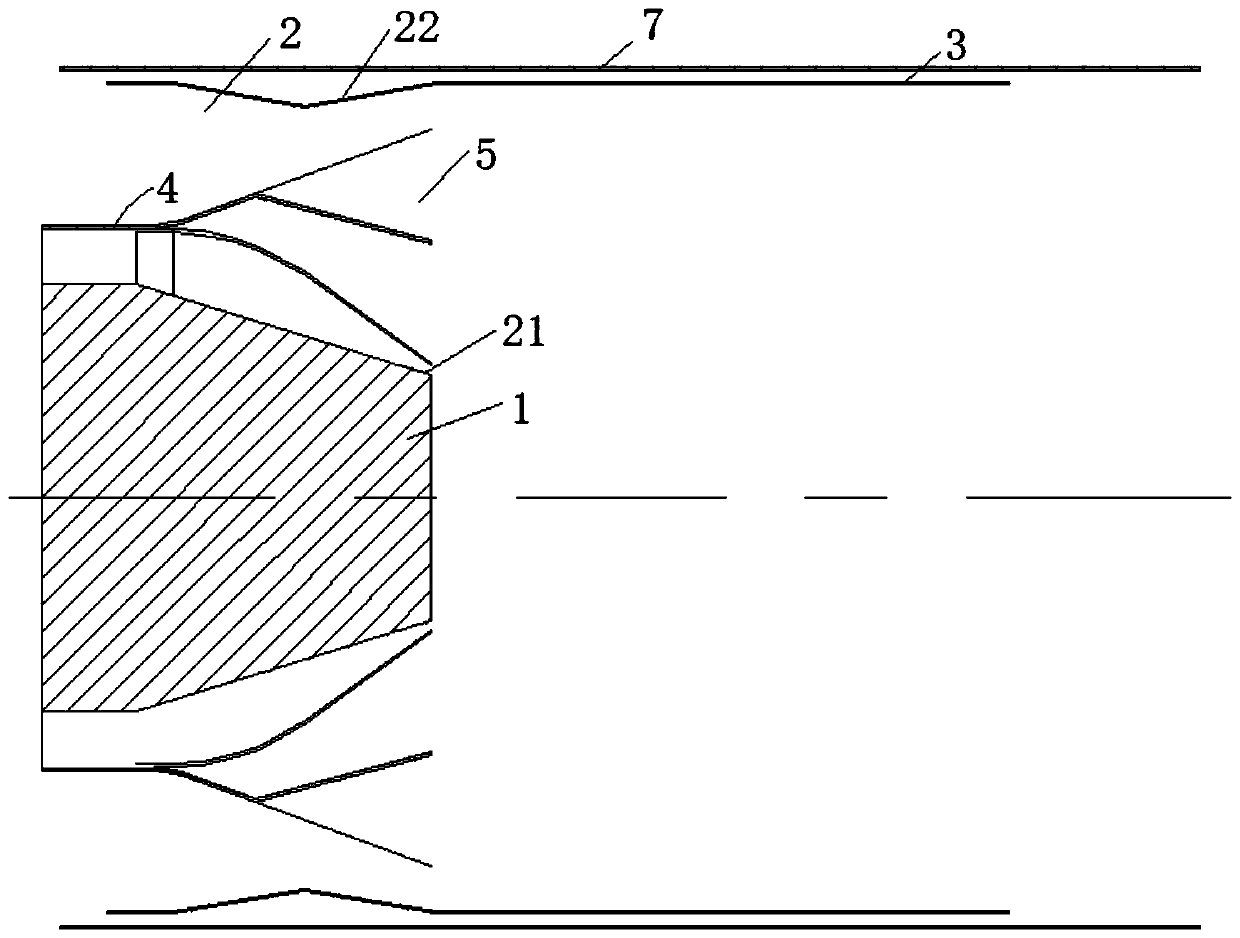

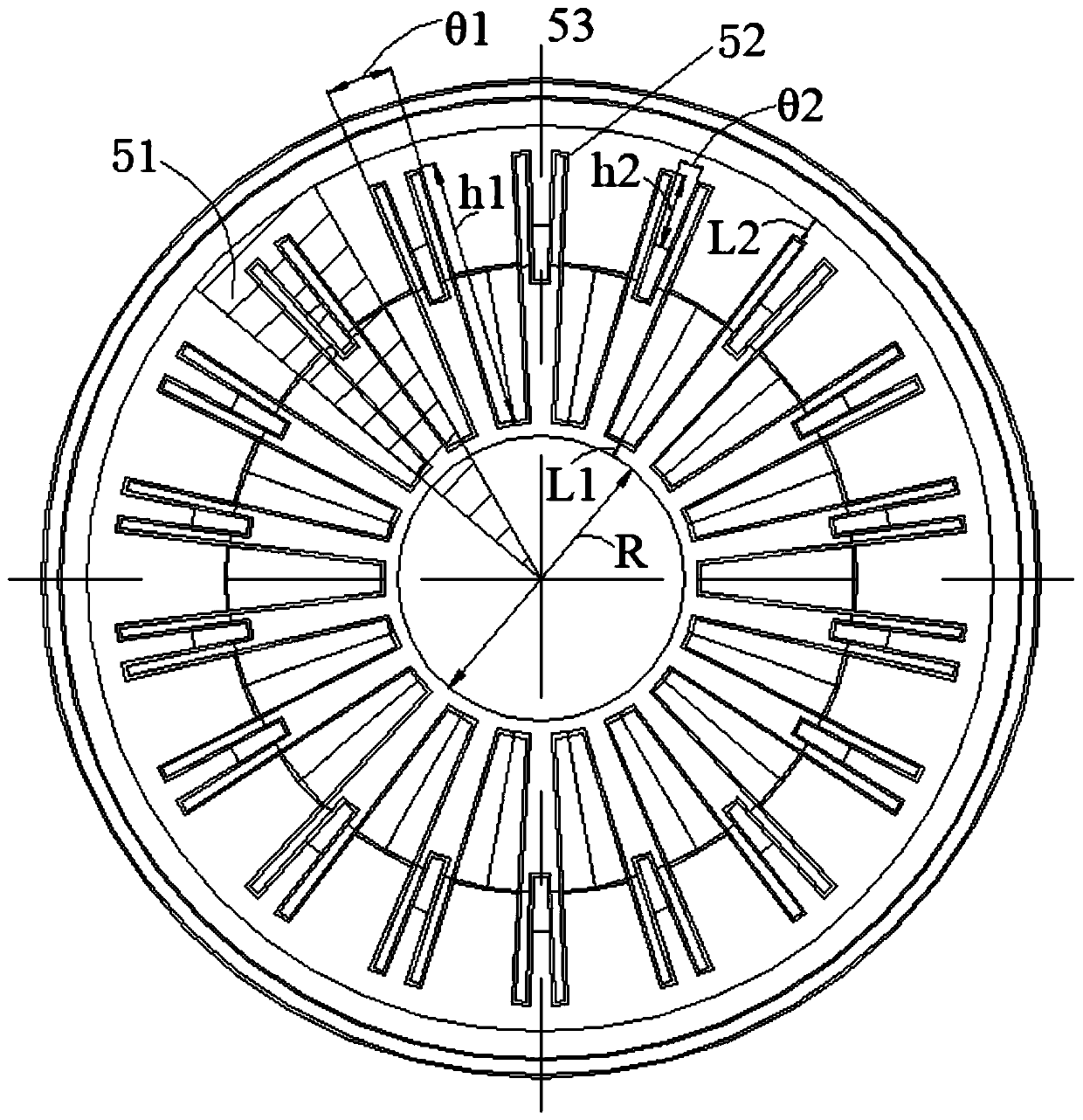

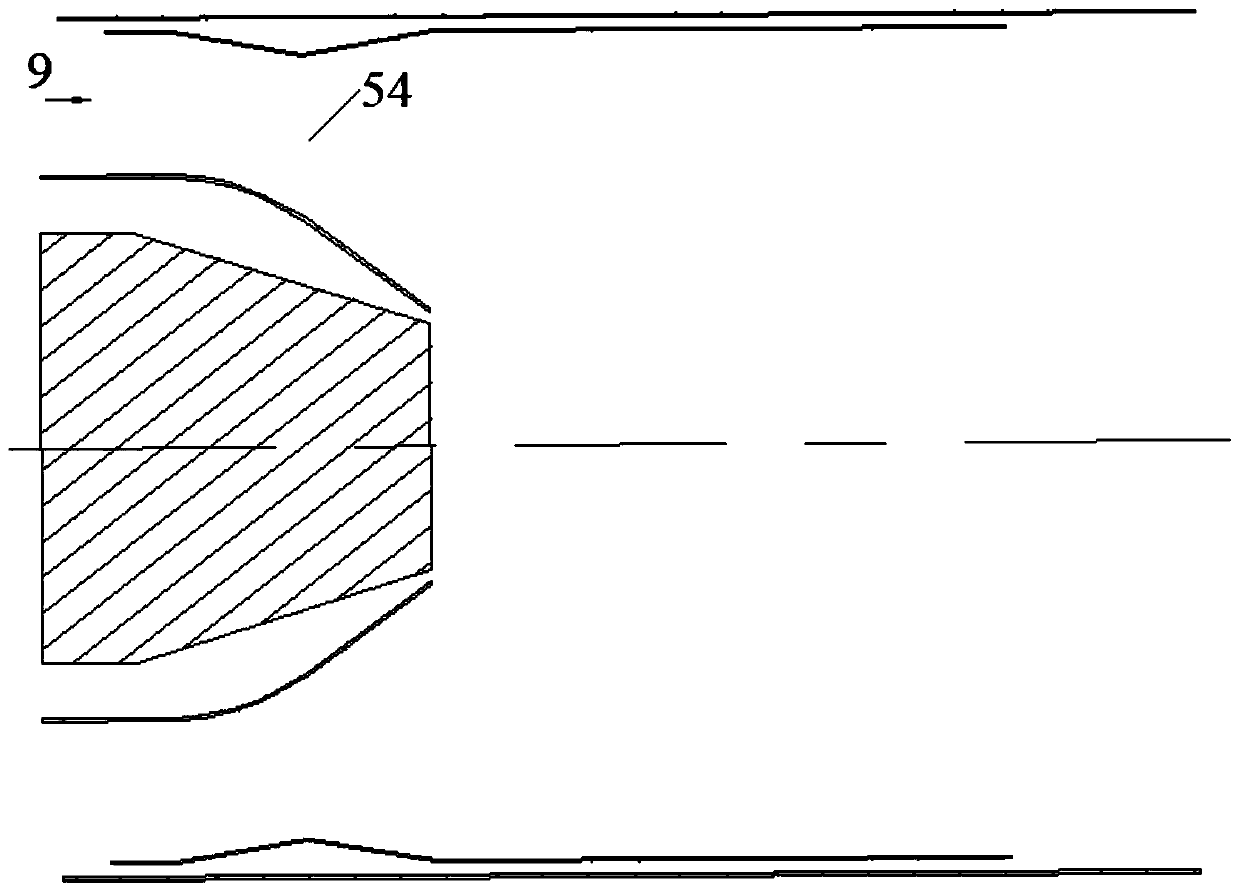

[0032] figure 1 A schematic structural diagram of a combustion chamber structure provided by an embodiment of the present disclosure is schematically shown. refer to figure 1 , combined with Figure 2-Figure 5 ,right figure 1 The structure shown is described in detail.

[0033] The combustion chamber structure in the embodiment of the present disclosure is applied in the afterburner of a turbojet engine with a wide speed range and high thrust-to-weight ratio, and the combustion chamber structure is located behind the low-pressure turbine. The combustion chamber structure includes a truncated cone 1 , a diffuser 2 , a flame tube 3 , a guide ring 4 , a lobe mixer 5 and a casing 7 .

[0034] The truncated cone 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com