Device and method for obtaining purification efficiency of high radioactive gas purification equipment

A technology for radioactive gas and purification equipment, which is applied to measurement devices, testing of mechanical components, and testing of machine/structural components, etc., can solve problems such as reduced purification performance, threats to the surrounding environment and personnel safety, and untimely replacement of purification equipment. Achieve the effect of ensuring and personnel safety and ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

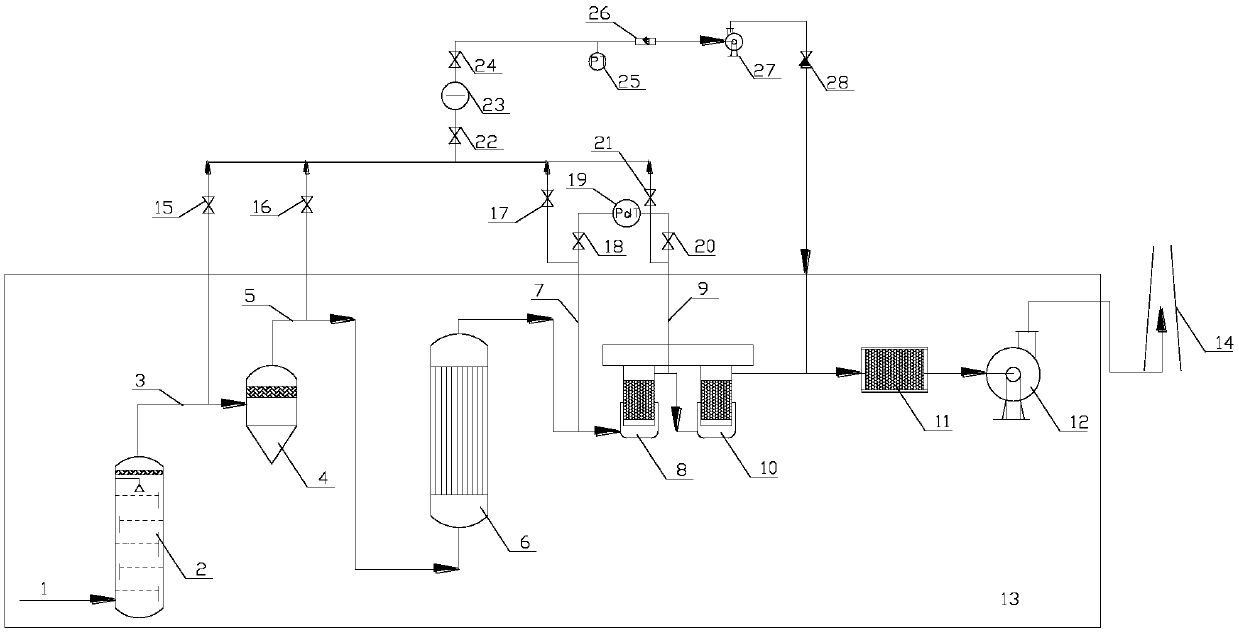

[0067] Such as figure 1 A device for obtaining the purification efficiency of strong radioactive gas purification equipment is shown, including a manual stop valve, a sampling box (23), a pressure gauge (25), a flow meter (26), a vacuum pump (27), and a check valve (28) .

[0068] The strong radioactive gas process exhaust system is composed of multiple strong radioactive gas purification equipment connected, specifically including the elution tower (2), trap (4), and gas cooler (6) connected in sequence inside the equipment room (13) , medium-efficiency filter (8), high-efficiency filter A (10), high-efficiency filter B (11), blower fan (12), and the chimney (14) that is positioned at the outside of equipment room. In parallel with the medium-efficiency filter (8), a differential pressure gauge (19) is provided, and the front pipel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com