Apparatus and method for studying heat transfer and flow laws in the tubular heating process of oil storage tanks

A tubular heating and oil storage tank technology, which is used in measurement devices, fluid dynamics tests, material thermal development, etc. to achieve the effect of convenient operation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

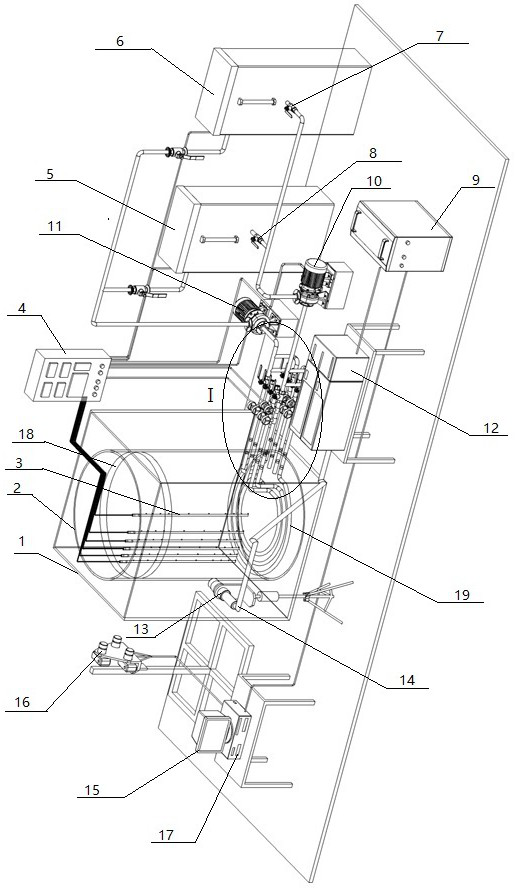

[0036] The present invention will be further described below in conjunction with the accompanying drawings:

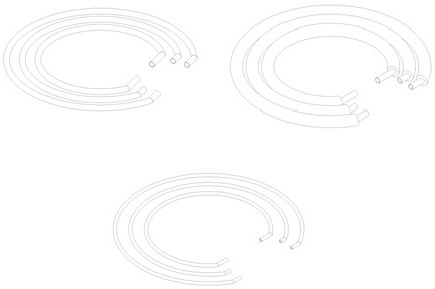

[0037] The invention can simulate the tubular heating process of the oil storage tank, and by installing heating pipes of different types and specifications in the tank, and adjusting parameters such as the flow rate and temperature of the heat transfer medium in the heating pipe, the experimental medium is heated under different conditions. The temperature field and velocity field in the process were recorded, parameters such as synergy angle and temperature field uniformity were calculated, and the influence of different heating tube structures and geometric dimensions and heating parameters on the heating effect of the tube was studied. The experimental device has a reasonable structure, easy to control experimental conditions, many test conditions, accurate test data, and can realize the visualization of the temperature field and the velocity field of the medium in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com