Combined type grape vine cold-proof soil clearing machine based on automatic leveling system

An automatic leveling, combined technology, applied in the fields of soil preparation machinery, agricultural machinery and implements, applications, etc., can solve the problems of high labor intensity, incomplete soil removal, and easy to damage vines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

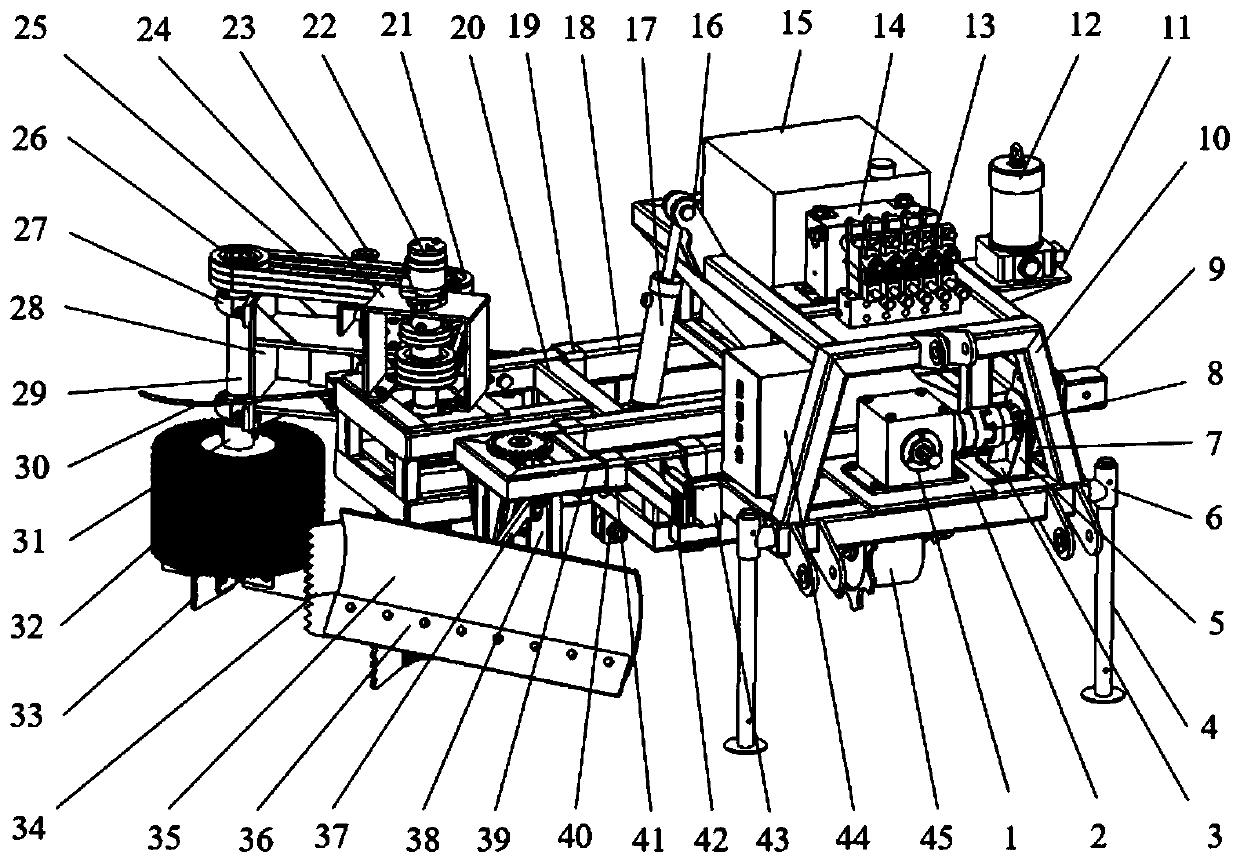

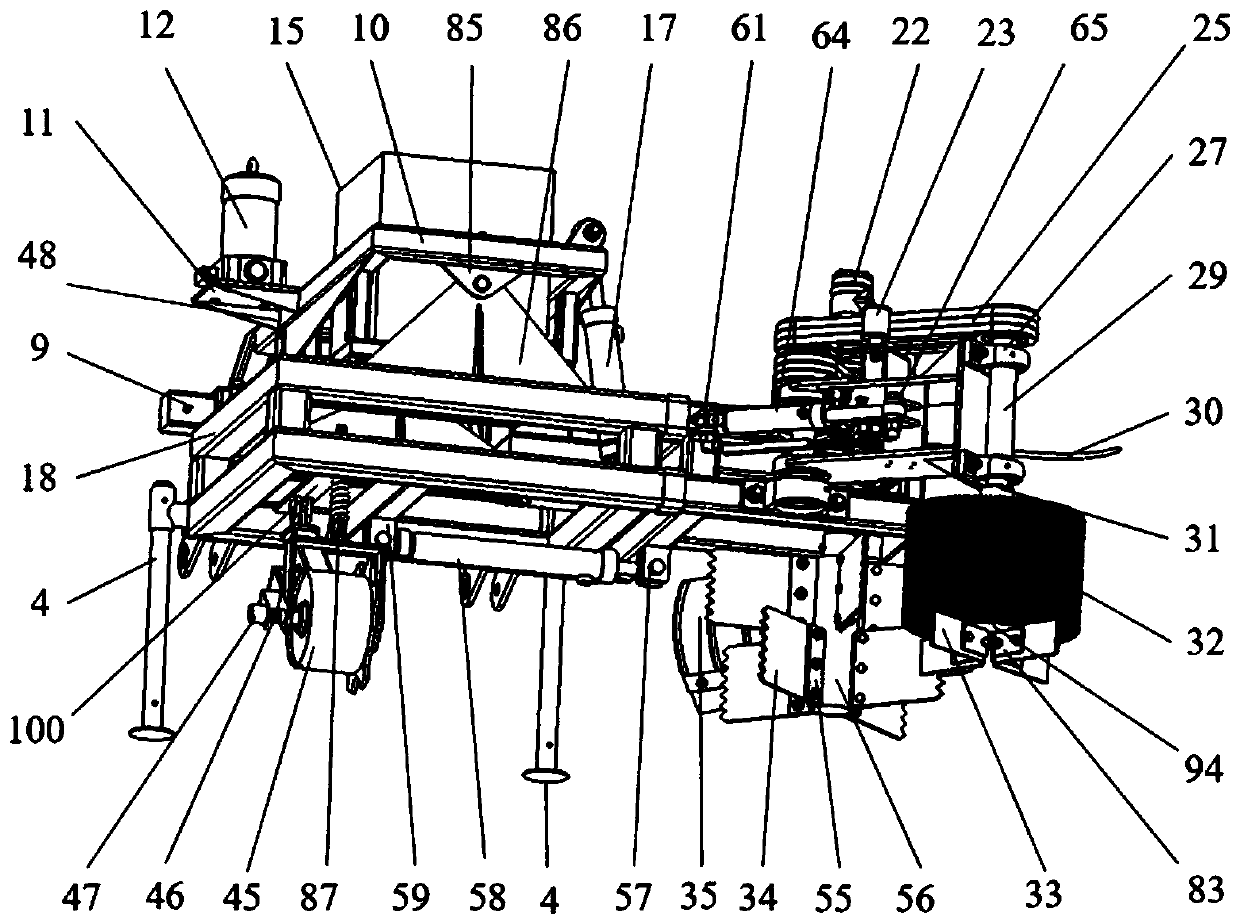

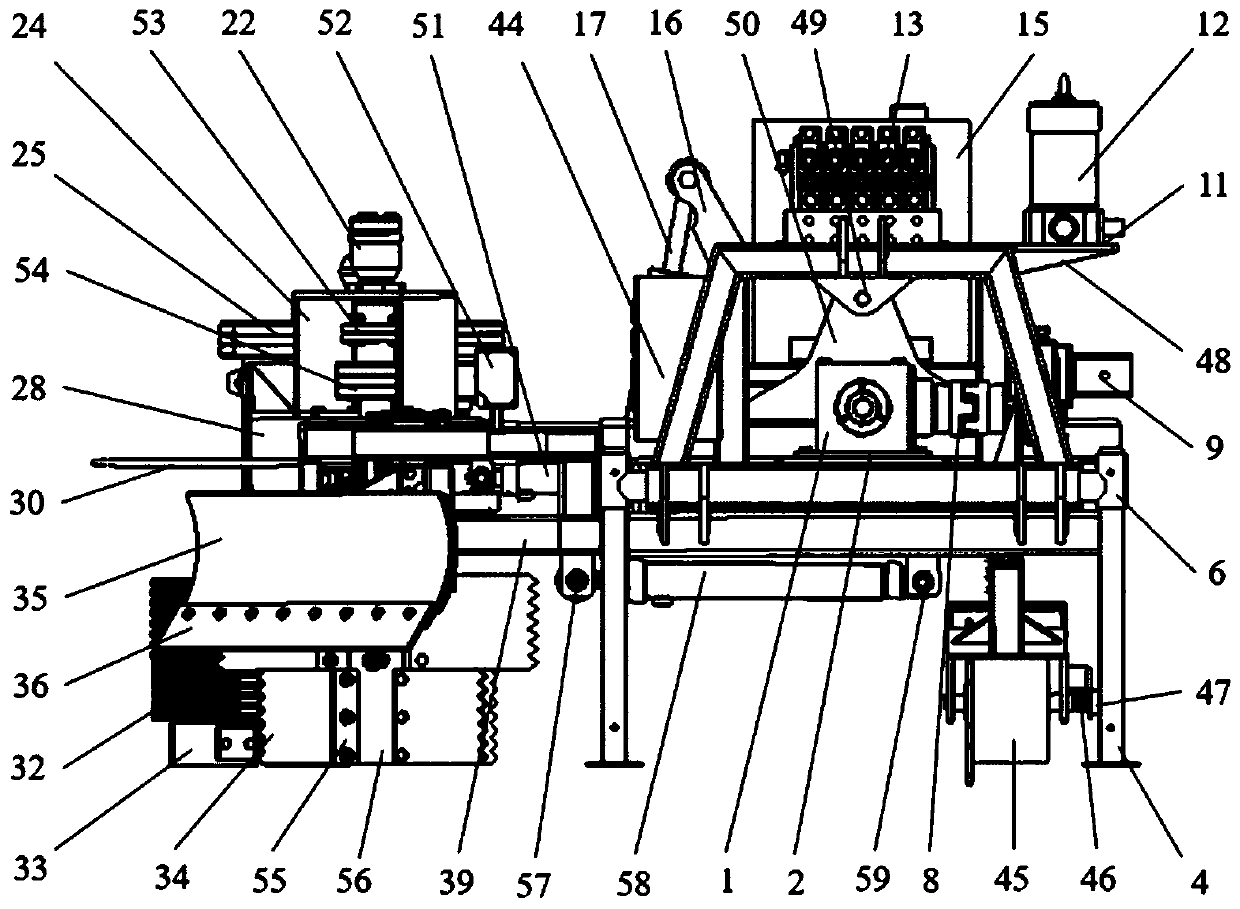

[0032] Attached below Figure 1-10 and the implementation manner, the specific implementation manner of the present invention is further described in detail. The following embodiments are only used to illustrate the present invention, but not to limit the scope of the present invention.

[0033] Such as Figure 1-10 As shown, a combined vine anti-cold soil remover based on an automatic leveling system, including a frame, moldboard parts, impeller parts, flexible brushes and rubber composite parts, automatic obstacle avoidance sensing mechanism, hydraulic system, control system, transmission system and speed measuring ground wheel;

[0034]The frame includes a main frame 10, a leveling frame 18, a width telescopic frame 20 and a moldboard installation frame 39, and a front side hinge plate 49 of the main frame is welded under the front beam of the main frame 10, so that The rear end beam of the main frame 10 is welded with a main frame rear hinge plate 85, and the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com