Temperature control sprinkler

A sprinkler and water pipe technology, applied in watering devices, gardening, botany equipment and methods, etc., can solve the problems of increasing people's labor, reducing enzyme activity, affecting plant growth, etc. effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

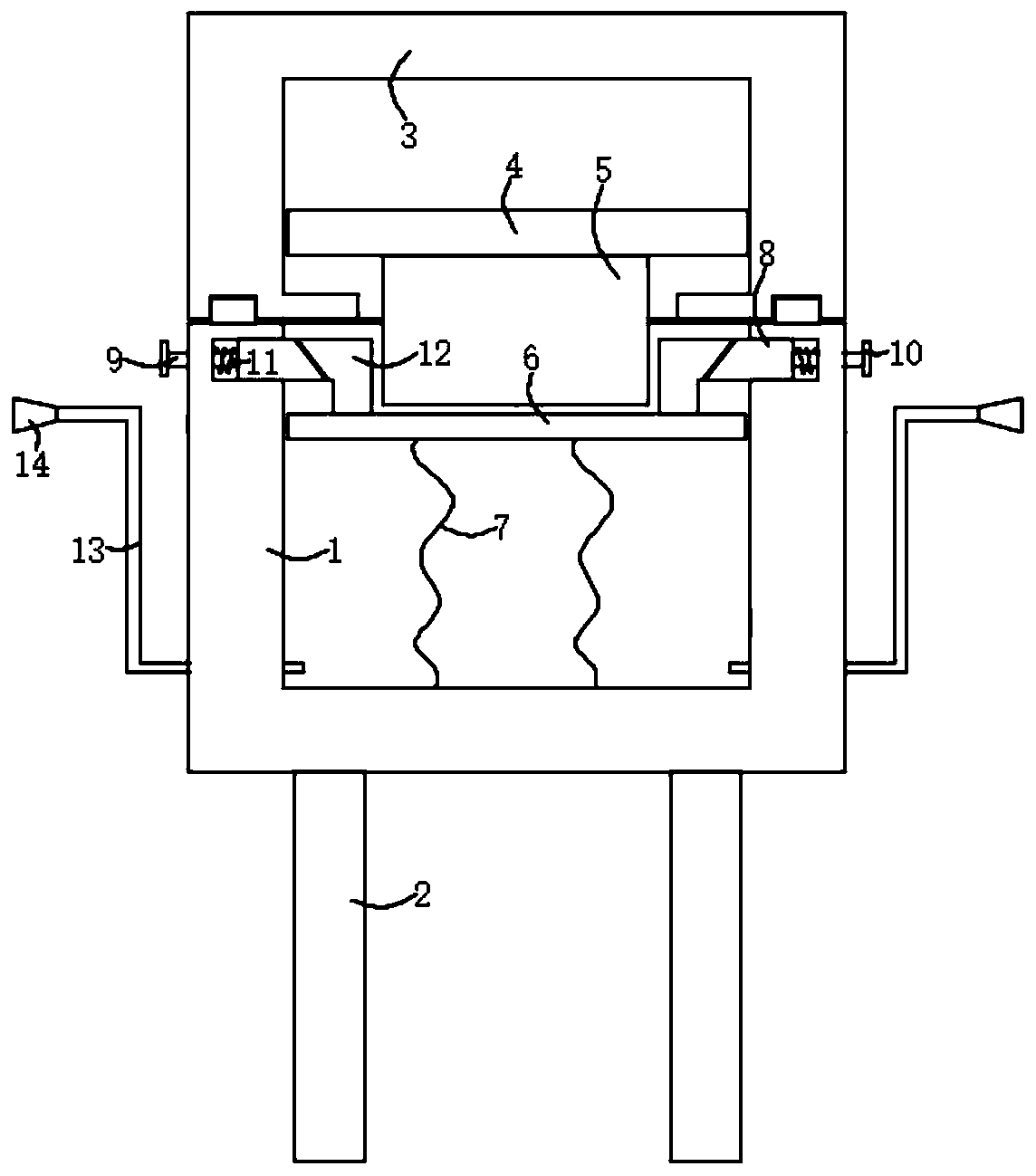

[0018] refer to figure 1 , a temperature-controlled sprinkler, comprising a base 1, a plurality of support rods 2 fixedly connected to the bottom of the base 1, a transparent top frame 3 threadedly connected to the base 1, and a first piston plate slidably connected to the inner side wall of the transparent top frame 3 4. The bottom of the first piston plate 4 is fixedly connected with a pressure block 5;

[0019] It should be noted that: the top of the base 1 is fixedly connected with a threaded ring, and the bottom of the transparent top frame 3 is provided with an annular threaded groove corresponding to the threaded ring, wherein the transparent top frame 3 is set to be transparent, which is convenient for people to see the first internal piston. The position of the plate 4, so as to judge whether to add water again.

[0020] Wherein, the base 1 is provided with a second piston plate 6, and the bottom of the second piston plate 6 is connected with the inner bottom of the ...

Embodiment 2

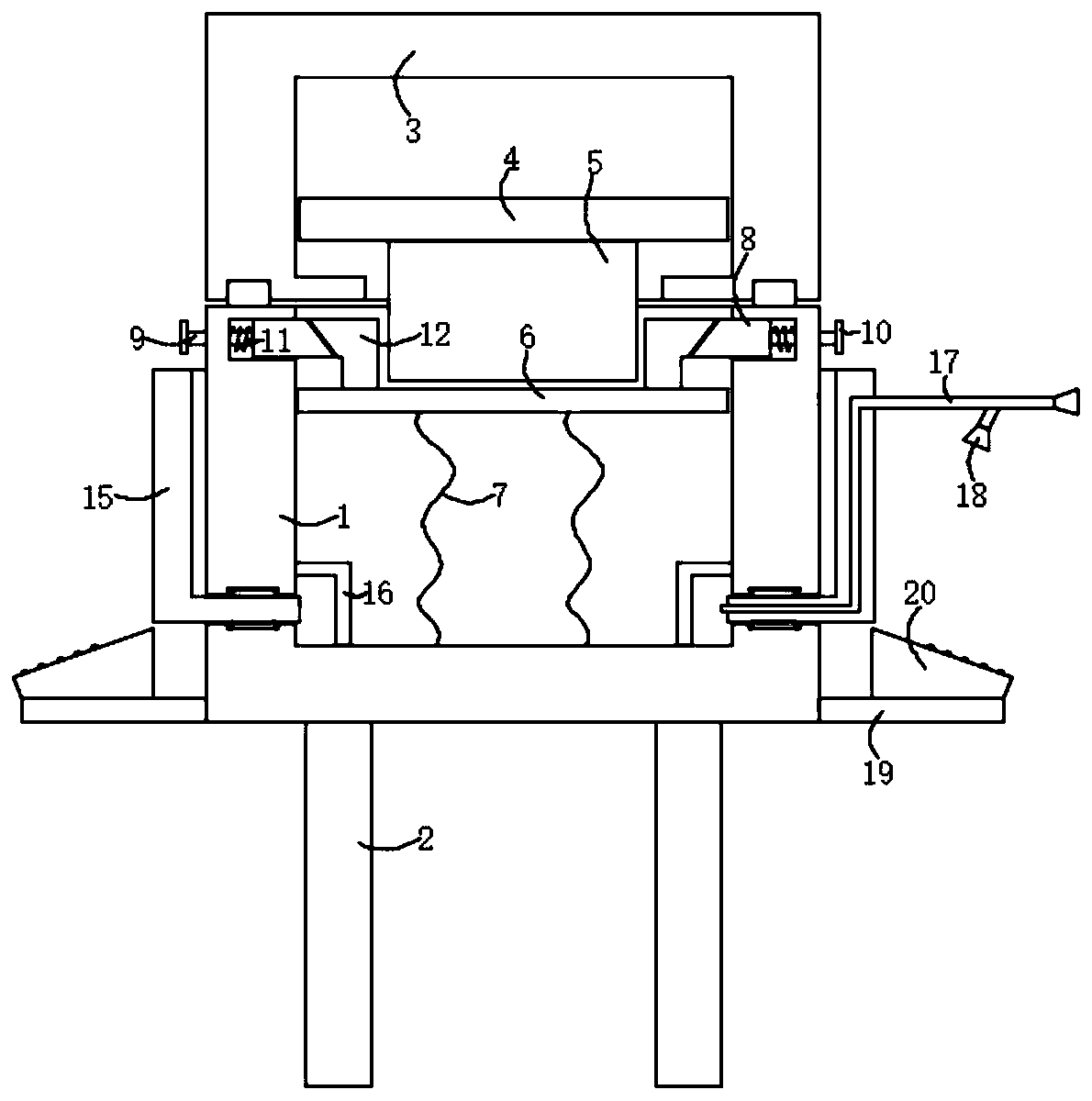

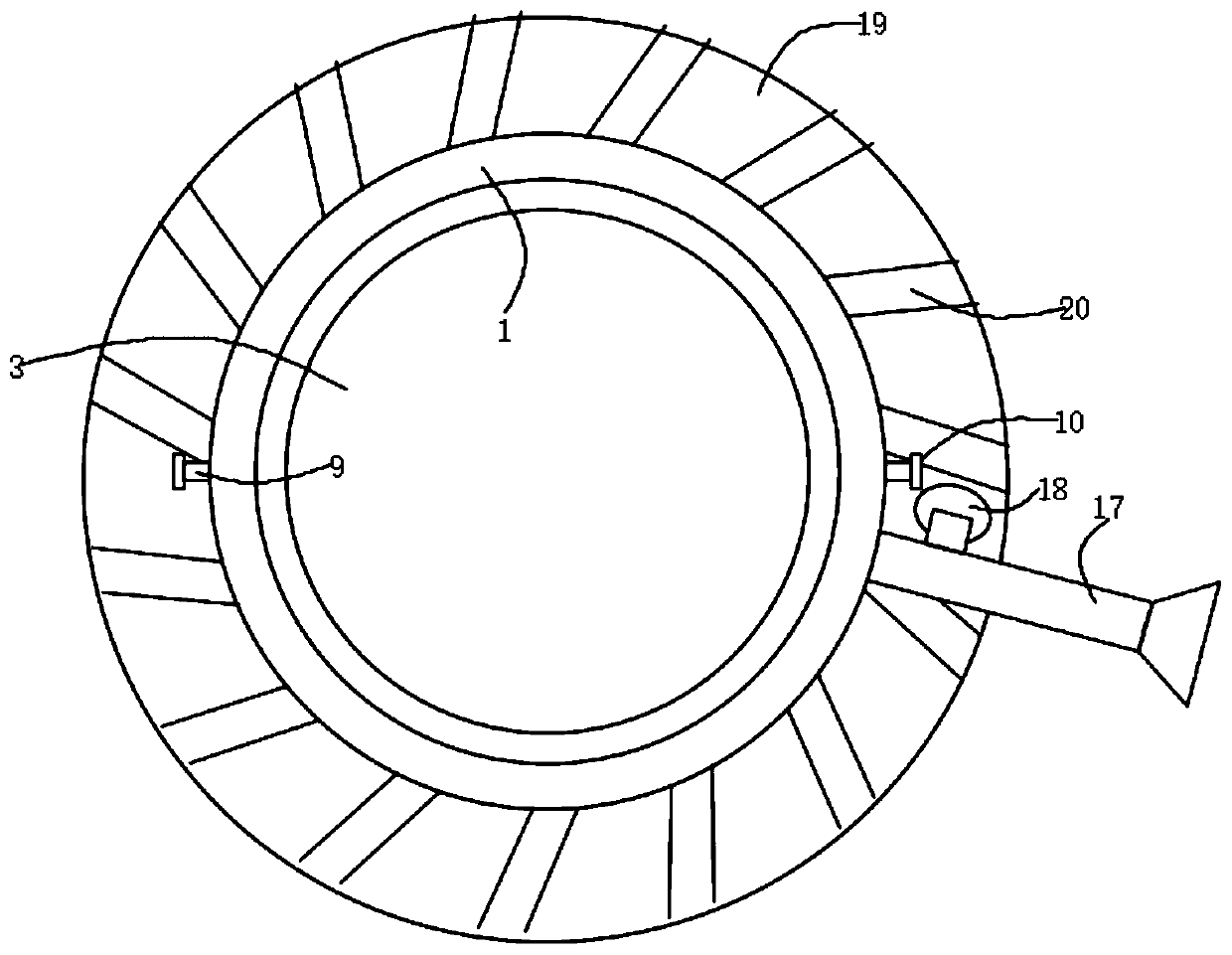

[0027] refer to Figure 2-3 The difference between this embodiment and Embodiment 1 is that the sprinkling mechanism includes a ring-shaped connection frame 15, the base 1 is provided with a rotating groove corresponding to the connection frame 15, and the inner wall of the base 1 is fixedly connected with a plurality of L-shaped fixed The rod 16 is fixedly connected with a plurality of second water pipes 17 in the connection frame 15, the second water pipe 17 is fixedly connected with a second nozzle at one end away from the connection frame 15, and the bottom of the second water pipe 17 is fixedly connected with a third nozzle 18 arranged obliquely , the outer side wall of the base 1 is fixedly sleeved with a mounting ring 19, and the top of the mounting ring 19 is fixedly connected with an obliquely arranged stopper 20, so that when the second piston plate 6 moves downward, the bottom of the second piston plate 6 will The water body sprays out from the second nozzle and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com