Control system of rotating end of CT system

A control system and rotary end technology, applied in general control systems, program control, computer control, etc., can solve the problems of high bus operation load, unstable communication, and many CAN bus messages, and improve stability, reduce CAN commands and message, the effect of reducing transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means of the present invention and the technical effects that can be achieved more clearly and more perfectly disclosed, an embodiment is provided hereby, and the following detailed description is given in conjunction with the accompanying drawings:

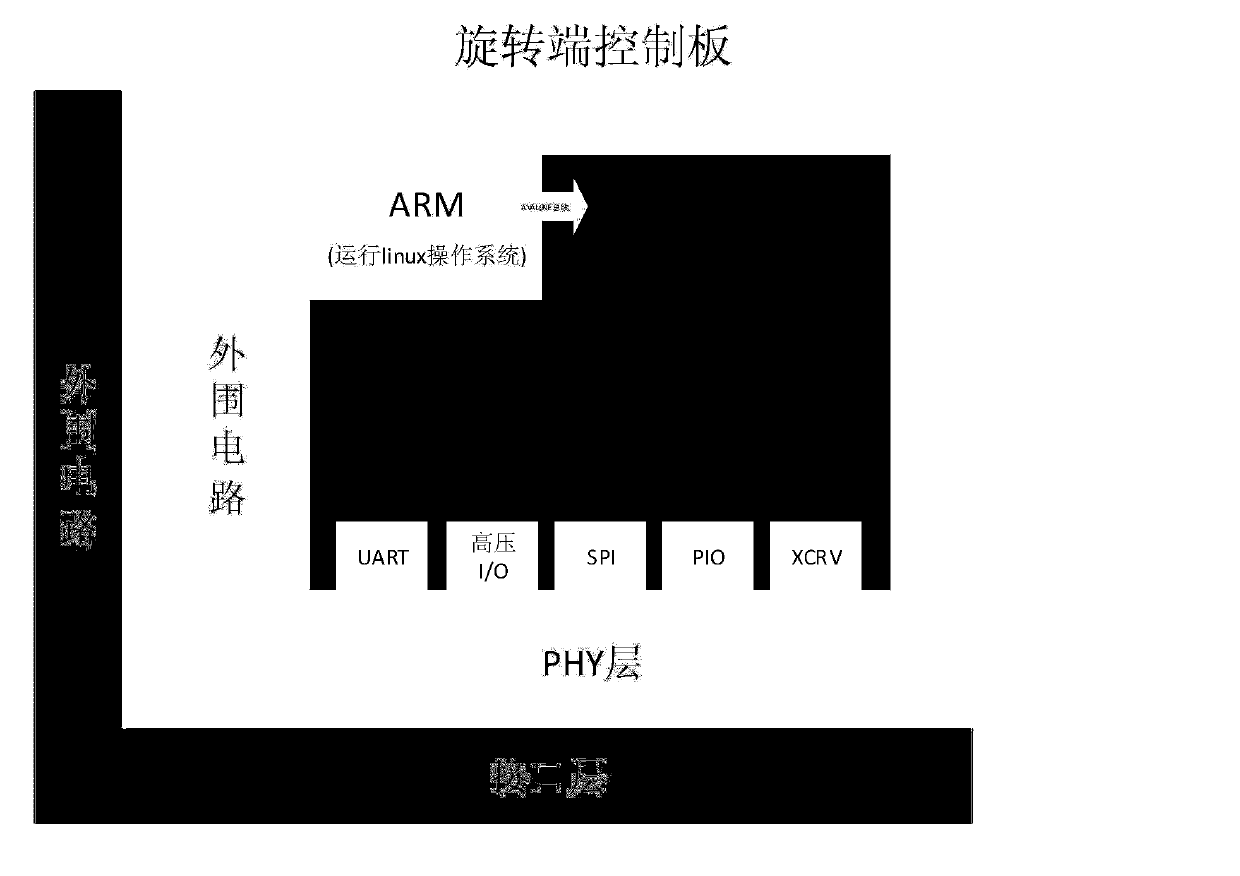

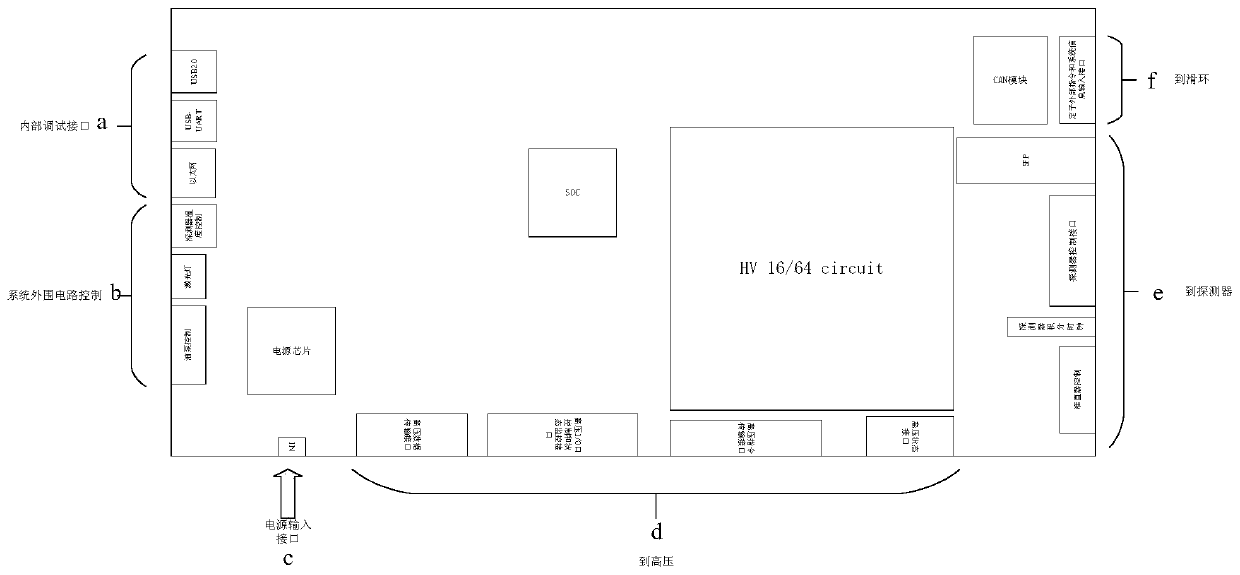

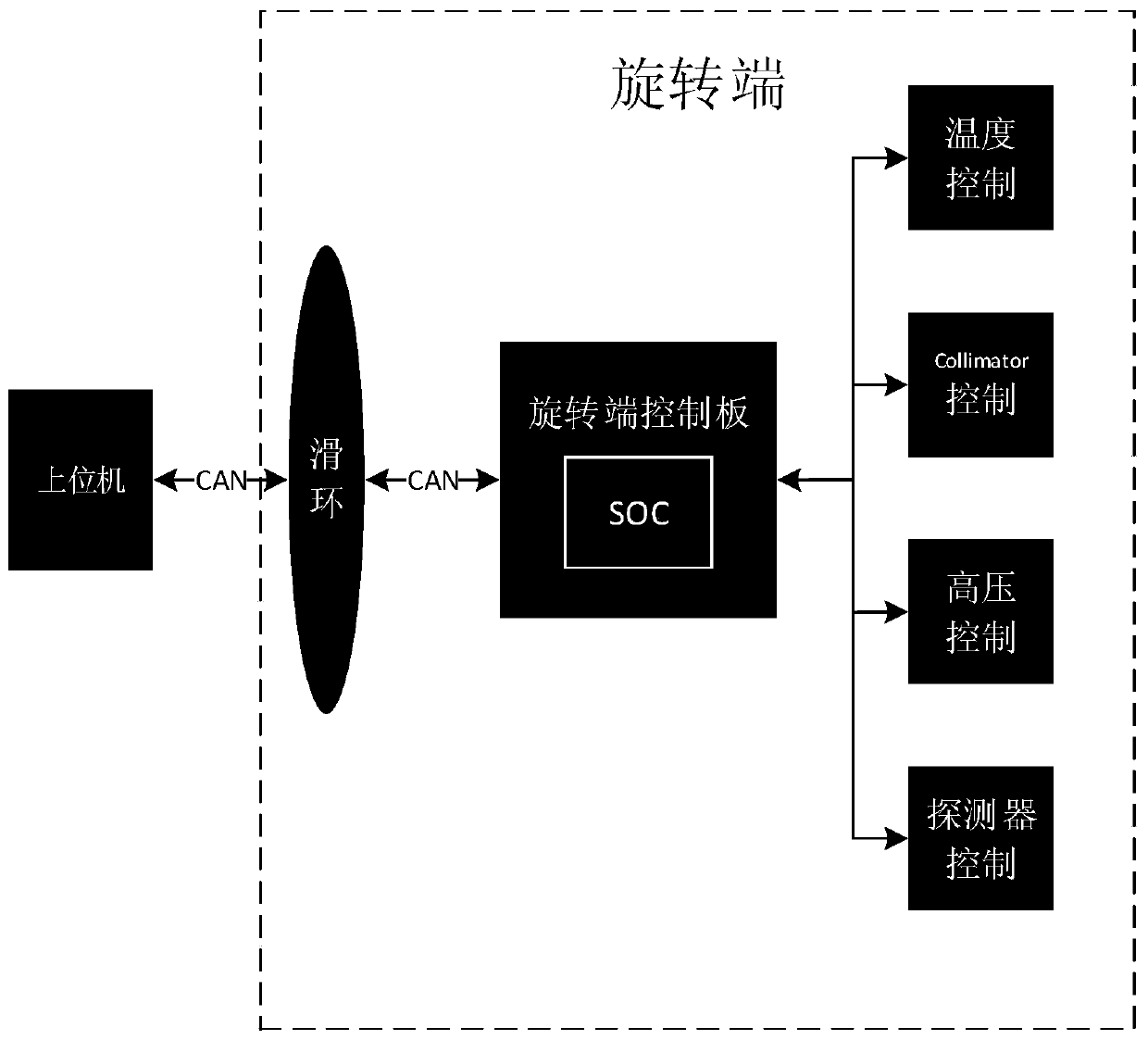

[0016] Such as Figure 1 to Figure 3 As shown, the control system of a rotating end of a CT system in this embodiment includes a host computer, a slip ring connected to the upper computer through a CAN bus, and a rotating end control board connected to the slip ring through another CAN bus; the rotating end control The board is connected to control the CT rotating end; the main control chip of the rotating end control board adopts the SOC chip containing the ARM part; the ARM part of the SOC chip runs the control logic, and the rotating end control board automatically runs the control command, sends the control command to the logic and receives the rotating end. feedback. The SOC chip descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com