Hair conditioner processing system, hair conditioner processing method and hair conditioner

A processing system and hair conditioner technology, applied in chemical instruments and methods, cleaning methods and utensils, hair care, etc., can solve the problem that residues cannot be scraped clean, and achieve the effect of avoiding residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

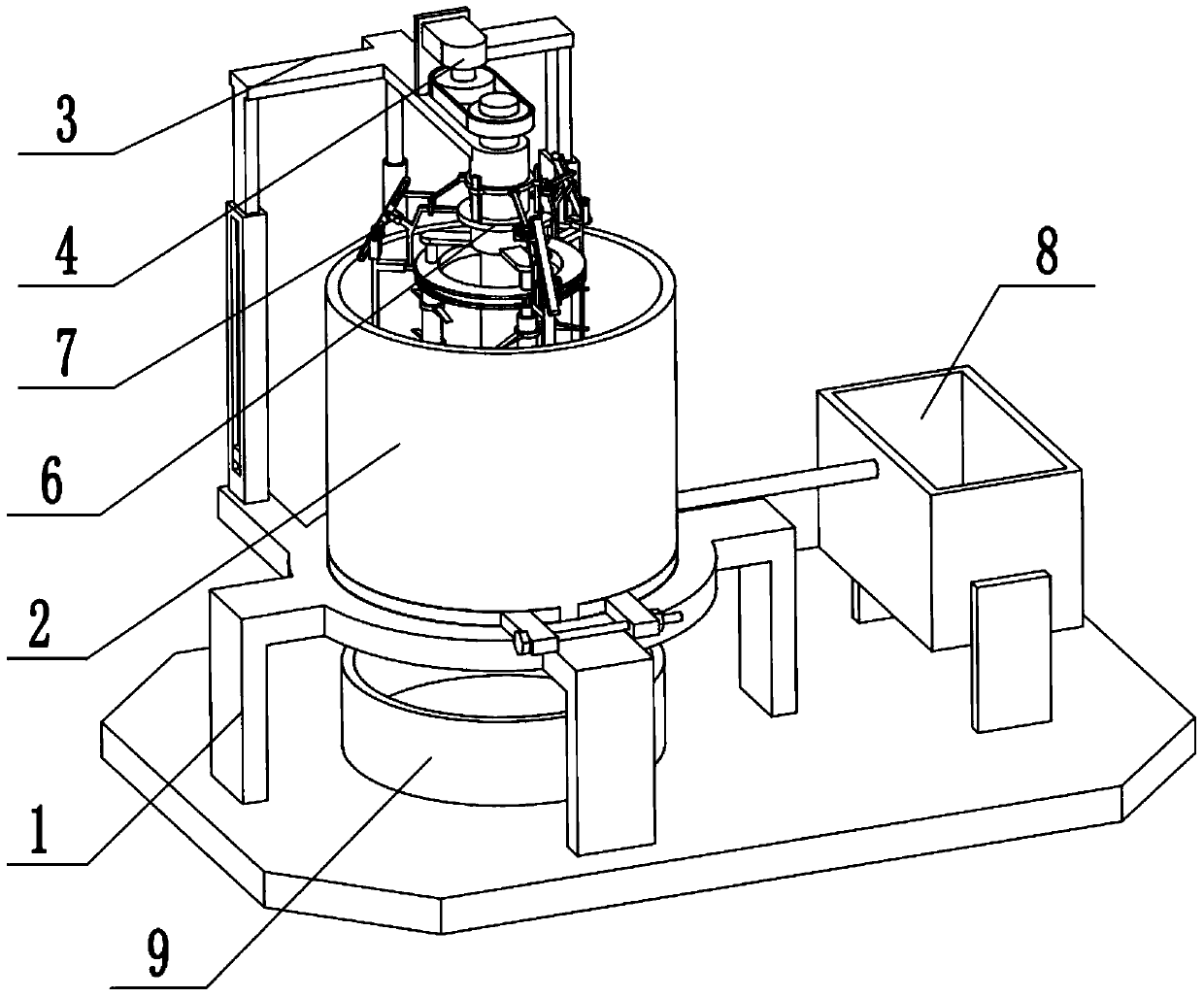

[0038] Combine below Figure 1-12 Illustrating this embodiment, a hair care liquid processing system includes a base assembly 1, a mixing drum assembly 2, a stirring mechanism 3, a power mechanism 4, a scraper member 5, a regulating member 6, a scraper driving member 7, a batching box 8 and The residue collection box 9, the mixing drum assembly 2 is arranged on the base assembly 1, the mixing mechanism 3 is cooperatively connected with the base assembly 1, the front end of the mixing mechanism 3 is located in the mixing drum assembly 2, and the power mechanism 4 is cooperatively connected with the mixing mechanism 3 , the scraper member 5 is movably connected to the power mechanism 4, the scraper member 5 is cooperatively connected to the stirring mechanism 3, the adjusting member 6 is movably connected to the stirring mechanism 3, and the scraper driving member 7 is connected to the scraper member 5 and the regulating member 6. , the batching box 8 is connected to the mixing ...

specific Embodiment approach 2

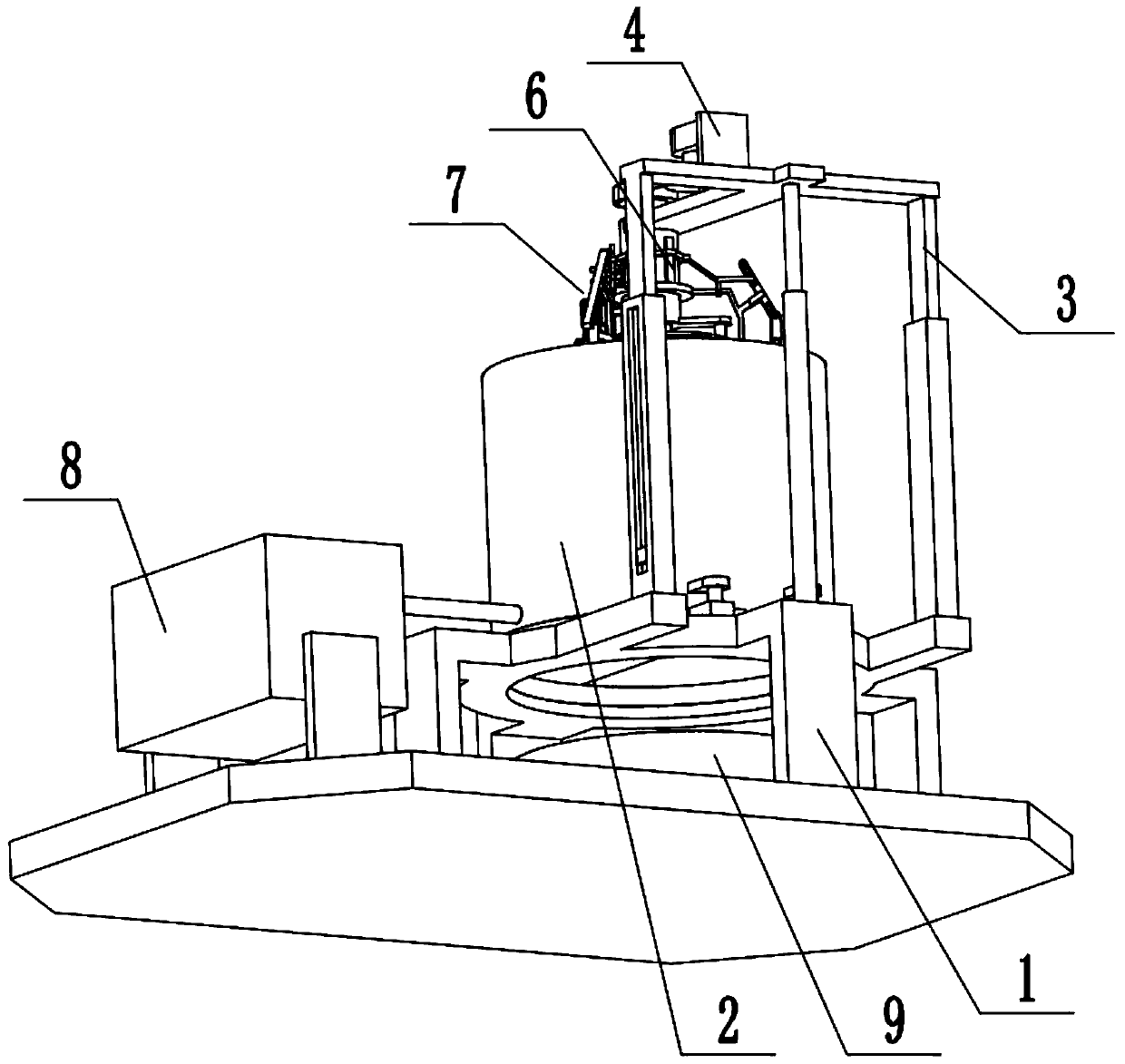

[0040] Combine below Figure 1-12 Illustrating this embodiment, the base assembly 1 includes an annular seat 1-1, a support foot 1-2, a bottom plate 1-3, an annular baffle 1-4, an electric telescopic rod 1-5, a sleeve rod 1-6 and a side slide Groove 1-7; annular seat 1-1 is set on the bottom plate 1-3 through four legs 1-2, the interior of annular seat 1-1 is provided with baffle 1-4, and the mixing drum assembly 2 is arranged on the annular seat 1- 1, the electric telescopic rod 1-5 is arranged at the rear end of the annular seat 1-1, the stirring mechanism 3 is connected with the electric telescopic rod 1-5, and the two sleeve rods 1-6 are symmetrically arranged at the rear end of the annular seat 1-1 , the two sleeve rods 1-6 are respectively provided with a side chute 1-7, the stirring mechanism 3 is connected with the two sleeve rods 1-6, the batching box 8 is fixed on the bottom plate 1-3 through the connecting plate, and the residue is collected. The box 9 is placed on...

specific Embodiment approach 3

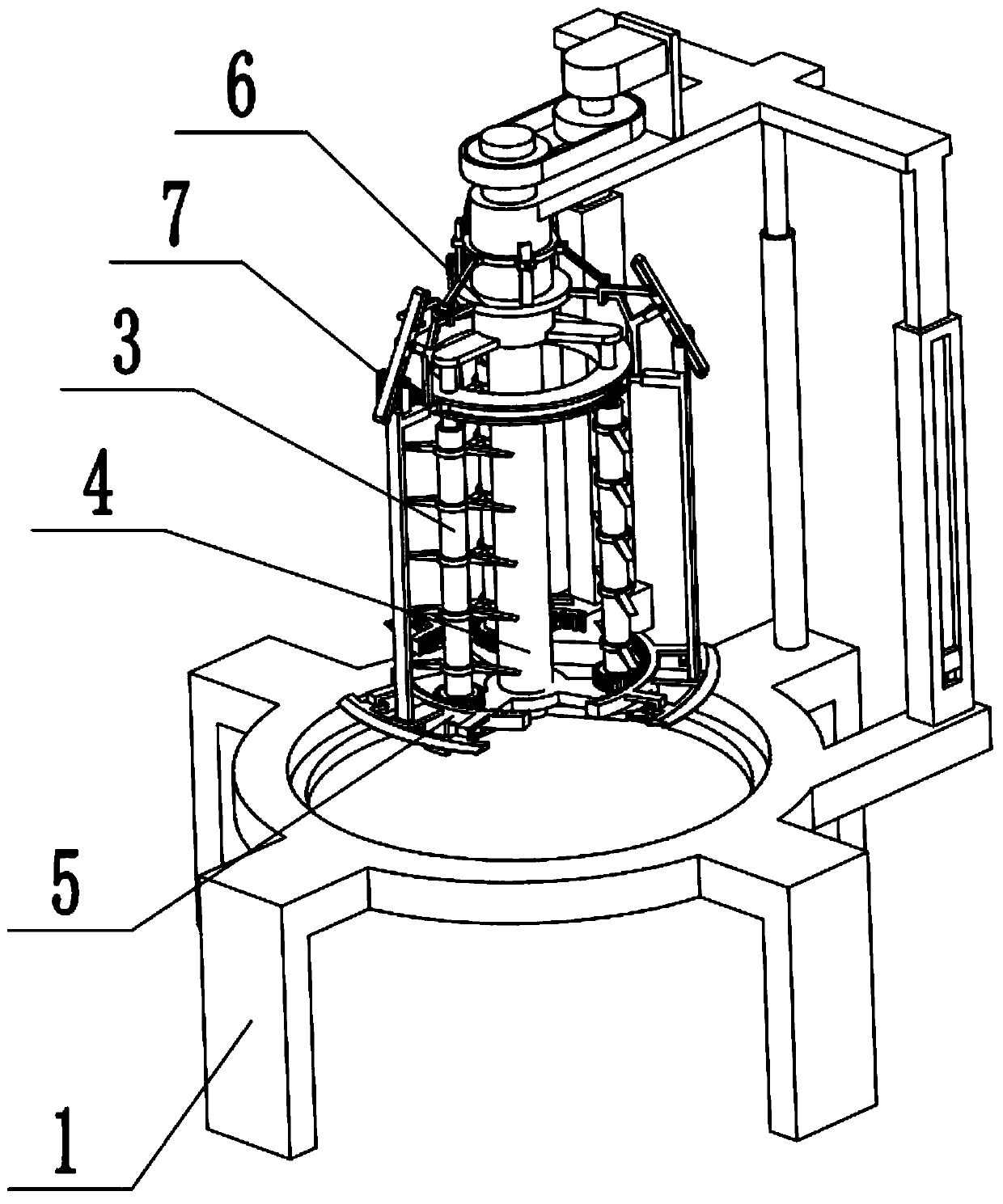

[0042] Combine below Figure 1-12 Illustrating this embodiment, the mixing drum assembly 2 includes a drum body 2-1, a baffle plate 2-2, a short shaft 2-3 and a long bolt 2-4; the drum body 2-1 is placed on the baffle 1-4 , the two baffles 2-2 are connected to the lower end of the cylinder body 2-1 in a symmetrical sealing and sliding fit, the two baffles 2-2 are both located at the upper end of the annular seat 1-1, and the two baffles 2-2 are rotatably connected to the Fixed on the two short shafts 2-3 on the barrel 2-1, the front ends of the two baffles 2-2 are connected by long bolts 2-4, the barrel 2-1 is connected with the ingredients through a hose with a control valve Box 8 is connected. After the hose is opened, the mixed liquid of the extracted hair care ingredients in the cylinder 2-1 flows into the ingredient box 8 through the hose, and other ingredients can be added to the ingredient tank 8 to obtain the hair care liquid; the liquid in the cylinder 2-1 The remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com