Plate-type flame arrester of which microchannels can achieve periodic backdrawing and outstretching

A periodic and micro-channel technology, which is applied in fire rescue and other fields, can solve the problems of large fluid resistance and achieve the effects of small fluid resistance, sufficient cooling effect and prolonged cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

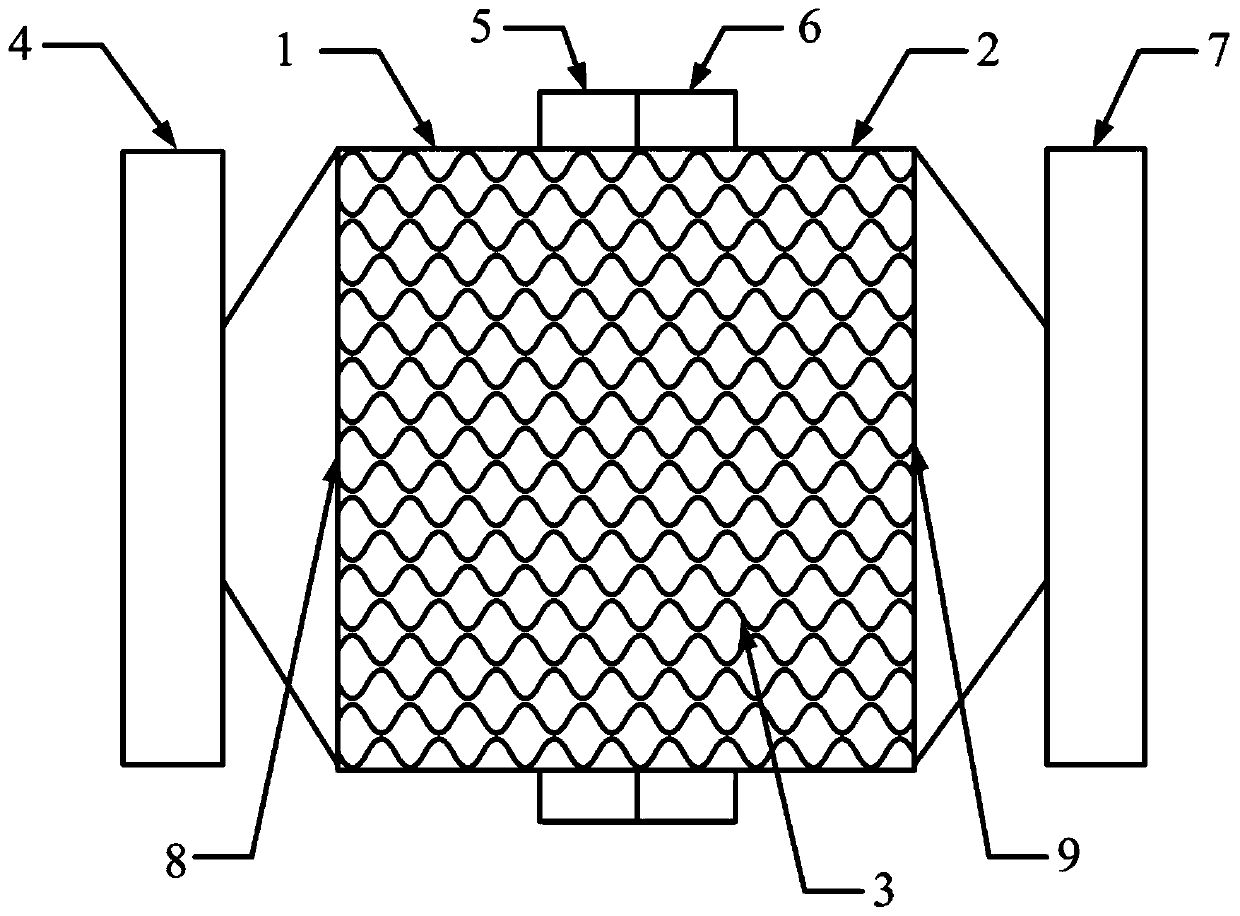

[0016] Such as Figures 1 to 2 As shown, a plate type flame arrester with microchannels periodically shrinking and expanding, including a cylinder and a fire arresting core 3, the cylinder includes a first cylinder 1 and a second cylinder 2, and the first cylinder 1 is connected by a flange Ⅱ5 is connected to flange Ⅲ6, specifically, flange Ⅱ5 and flange Ⅲ6 are sealed and connected through bolts and nuts, and gaskets are also provided between the bolts and nuts; the other end of the first cylinder 1 is also provided with a flange Ⅰ4, the other end of the second cylinder 5 is also provided with a flange IV7; the fire retardant core 3 is arranged in the cylinder, and the two ends of the fire retardant core 3 are respectively provided with a first support plate 8 and a second support plate 9, and the flange The first cylinder expansion cavity is formed between I4 and the first support plate 8, and the second cylinder expansion cavity is formed between the flange IV7 and the secon...

Embodiment 2

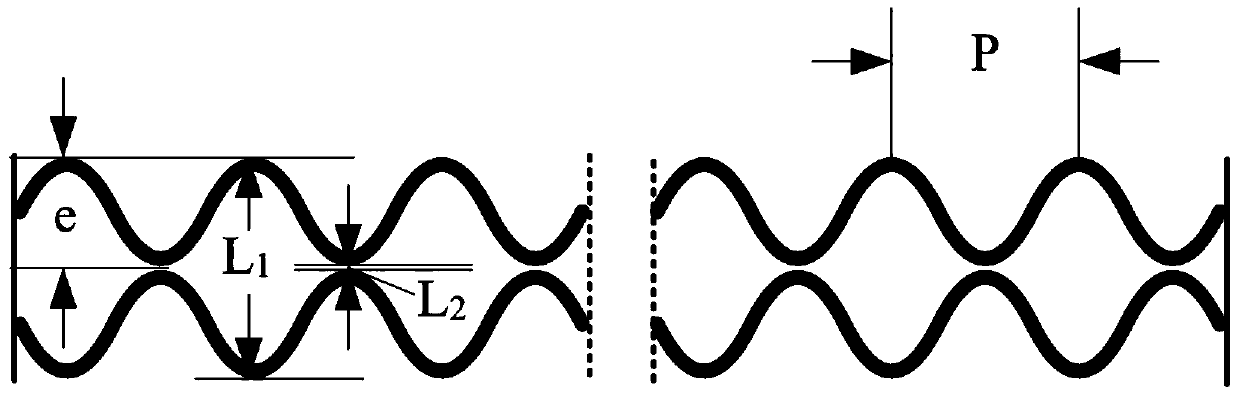

[0022] The difference from Example 1 is that in this example, the pitch P range of the stainless steel plate is 20 mm, and the contraction ratio a=L 1 / L 2 , and the contraction-expansion ratio a is 20, the range of rib height e is 5mm, the distance between the microchannels formed by the stainless steel plate is 5-20mm, and the expansion angles of the expansion cavity of the first cylinder and the expansion cavity of the second cylinder are both 10° .

Embodiment 3

[0024] Different from Example 1, in this example, the pitch P range of the stainless steel plate is 12mm, and the contraction ratio a=L 1 / L 2 , and the shrinkage-expansion ratio a is 10, the range of rib height e is 1.5mm, the distance between the microchannels formed by the stainless steel plate is 0.5-1.5mm, and the expansion angles of the expansion chamber of the first cylinder and the expansion chamber of the second cylinder are 60°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com