Automatic powder selecting control method, system and device for vertical mill classifier

A technology of control device and control method, which is applied in chemical instruments and methods, solid separation, and separation of solids from solids by air flow, etc., can solve the problem that the system cannot obtain the change nodes of the adjusted parameters, equipment waste, and judgment delay. and other problems, so as to reduce the steps of manual sampling and adjustment, and avoid the effect of different screening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

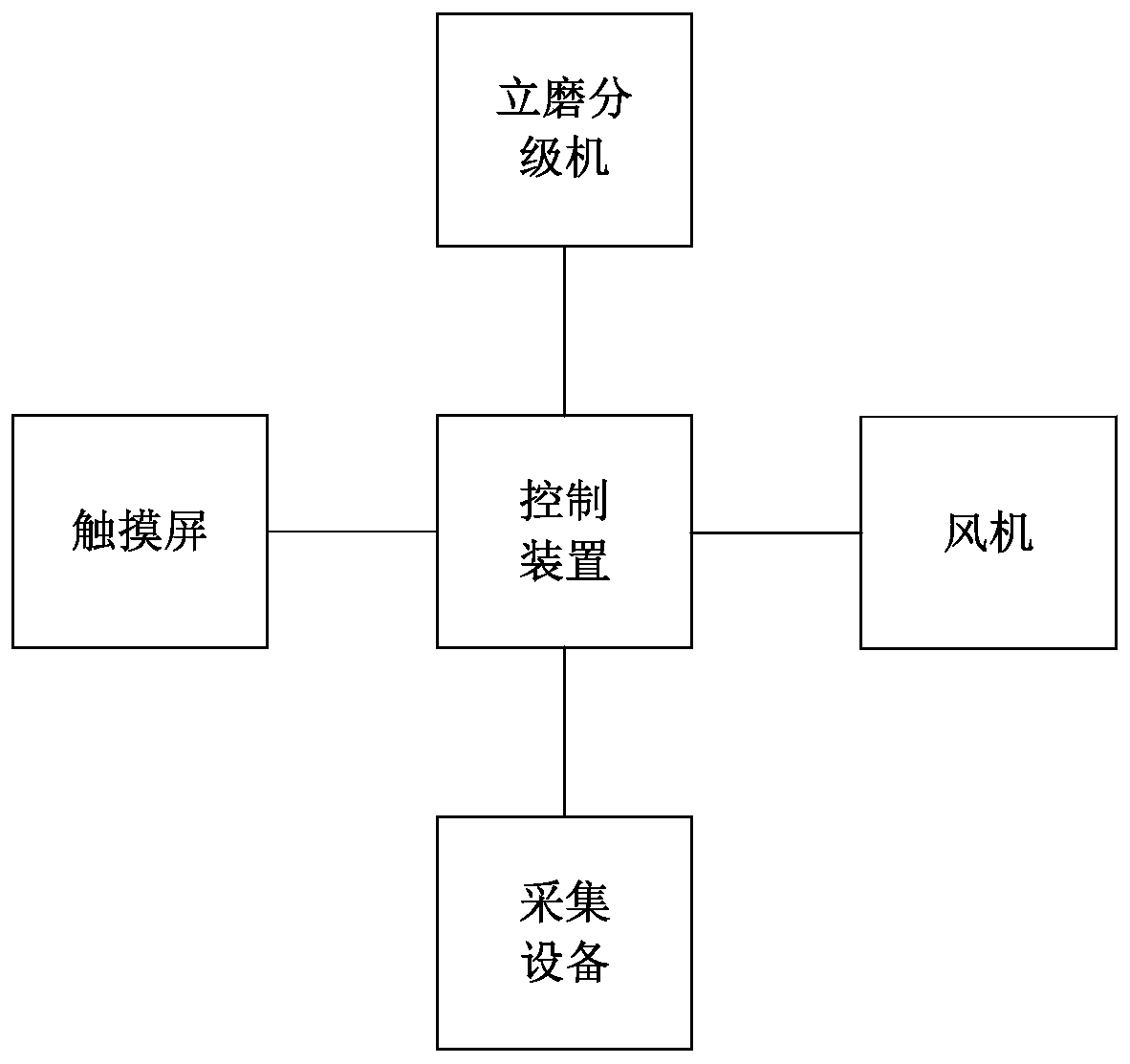

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

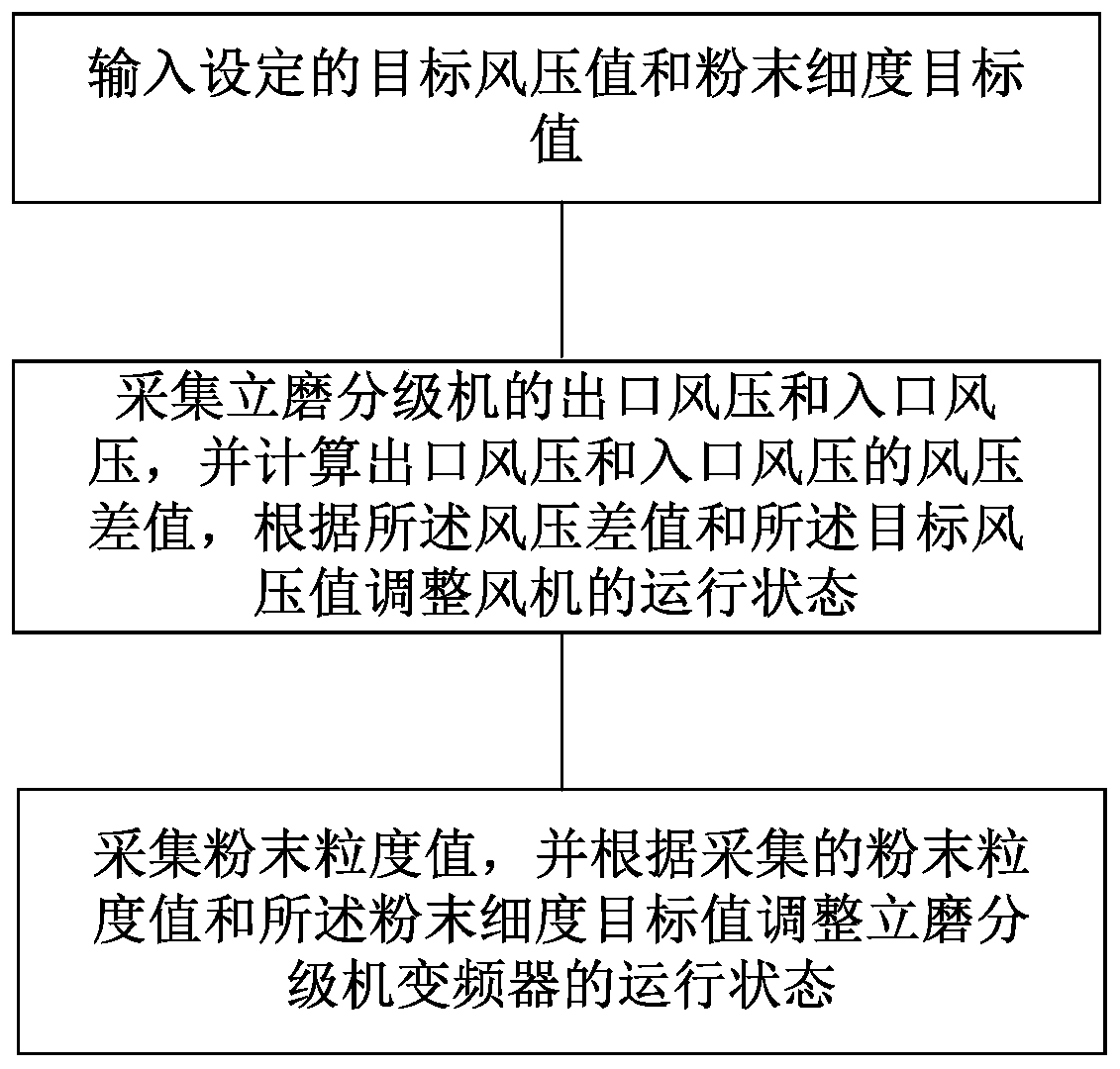

[0023] figure 1 It is a schematic flowchart of the automatic powder selection control method for the vertical mill classifier provided by the embodiment of the present invention.

[0024] Such as figure 1 As shown, a vertical mill classifier automatic powder selection control method, including:

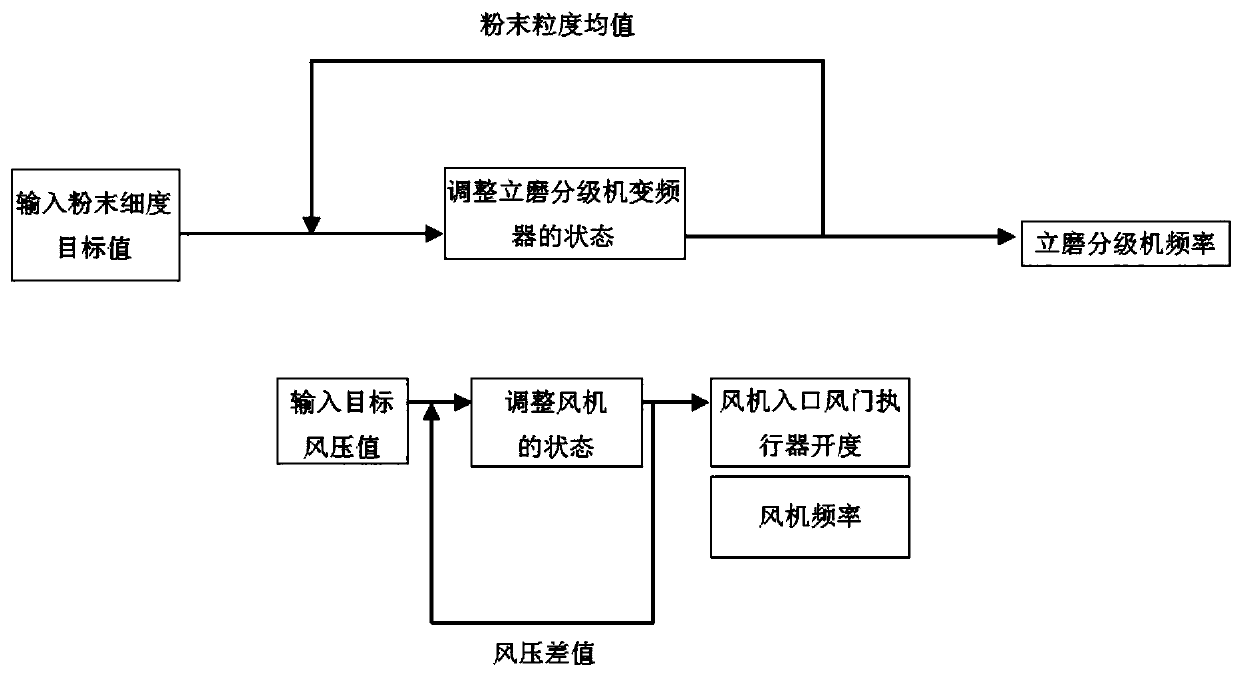

[0025] Input the set target wind pressure value and powder fineness target value;

[0026] Collect the outlet wind pressure and inlet wind pressure of the vertical mill classifier, and calculate the wind pressure difference between the outlet wind pressure and the inlet wind pressure, and adjust the operating state of the fan according to the wind pressure difference and the target wind pressure value;

[0027] The powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com