Radial floating grinding device and method for industrial robot

A technology of industrial robots and floating devices, which is applied to machine tools suitable for grinding the edge of workpieces, devices for fixing grinding wheels, and safety devices for grinding/polishing. problems, to achieve the effect of avoiding restrictions, high degree of automation, economical and practical scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

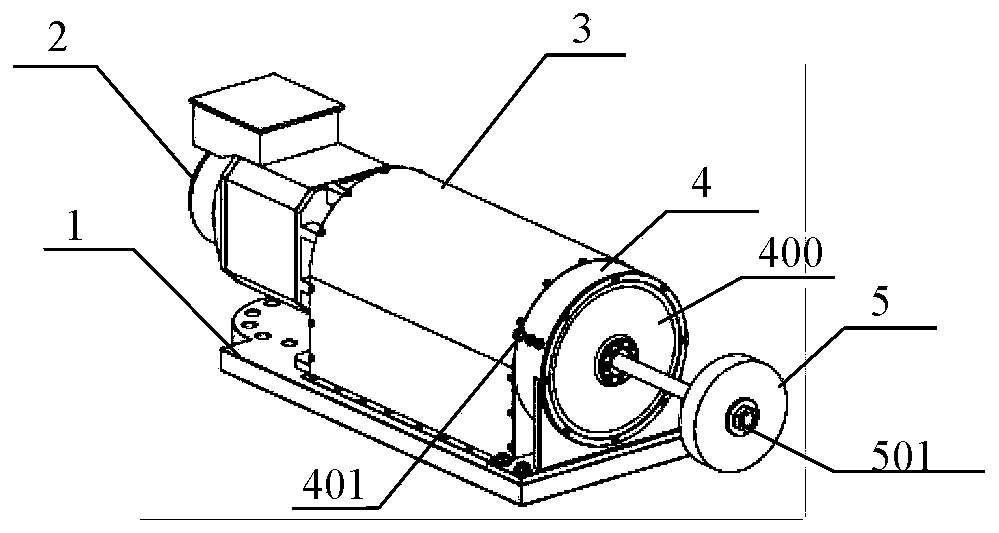

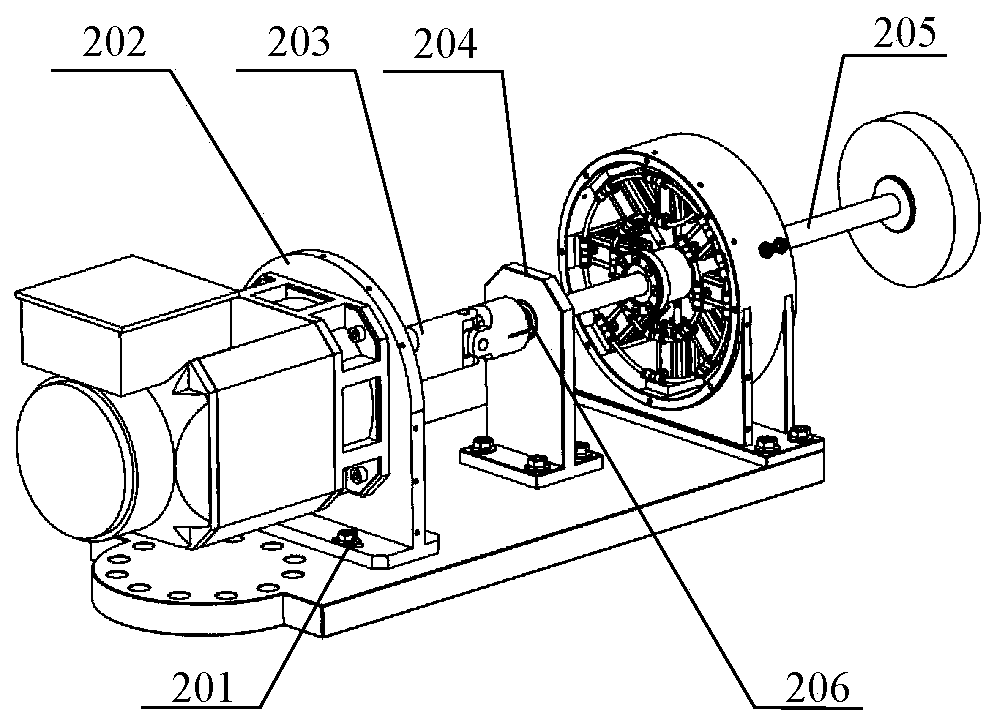

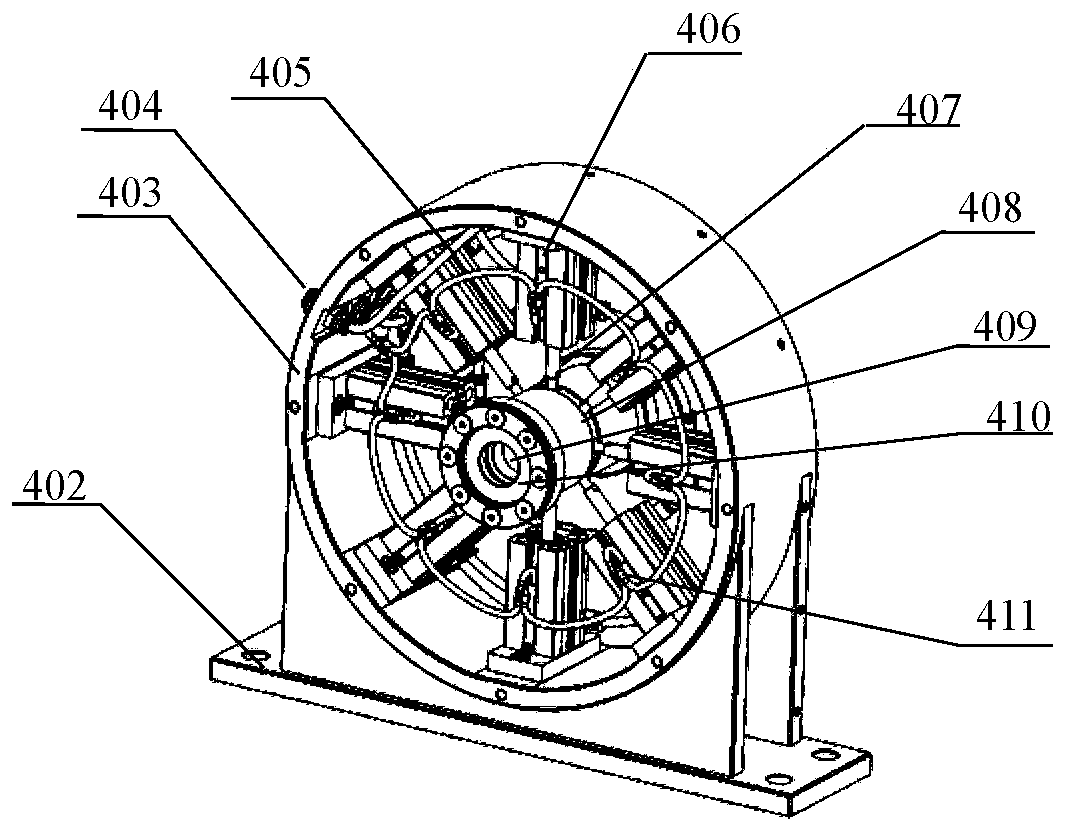

[0042] Such as Figure 1 to Figure 4 As shown, the radial floating grinding device for industrial robots provided in this embodiment includes a flange mounting plate 1, a grinding motor 2, a grinding motor mounting plate 202, a cross universal joint 203, a protective cover 3, and a radial floating device 4. Grinding tools;

[0043] The flange mounting plate 1 is arranged on the grinding robot for fixing the whole device, the grinding motor mounting plate 202 is arranged on the flange mounting plate 1, and the grinding motor 2 in this embodiment is mounted on the motor through fixing bolts. On the mounting plate 202, the grinding motor is fixed on the grinding motor mounting plate 202 by bolts, and the motor mounting plate 202 is mounted on the flange mounting plate 1 by bolts to support and fix the grinding motor 2; One end of the universal joint 203 is connected with the output shaft of the grinding motor 2, and the other end is connected with the connecting rod of the grind...

Embodiment 2

[0065] This embodiment provides a radial floating grinding method for industrial robots, comprising the following steps:

[0066] Start the grinding motor to work, and the output shaft of the grinding motor drives the grinding tool fixed on the connecting rod to rotate through the universal joint assembly;

[0067] Grinding the workpiece to be polished by grinding tools;

[0068] By adjusting the floating air pressure of the cylinder in the radial floating device, the support force generated by the movable axis of the cylinder on the supporting surface of the connecting rod in any direction remains constant; thereby controlling the pressure of each cylinder in the radial floating device on the supporting surface of the connecting rod.

[0069] The specific process of the radial floating grinding method provided in this embodiment is as follows:

[0070] During the grinding operation, by driving the grinding motor to work, the output shaft of the grinding motor is driven by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com