Thin-walled multicellular filled energy-absorbing structures and calculation method of average compressive force of energy-absorbing structures

An energy-absorbing structure and calculation method technology, which is applied in complex mathematical operations, railway car body parts, transportation and packaging, etc., can solve problems such as large initial peak force, weak lateral load, and small energy absorption of energy absorbers, and achieve Small initial peak force, reduced weight, and high energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

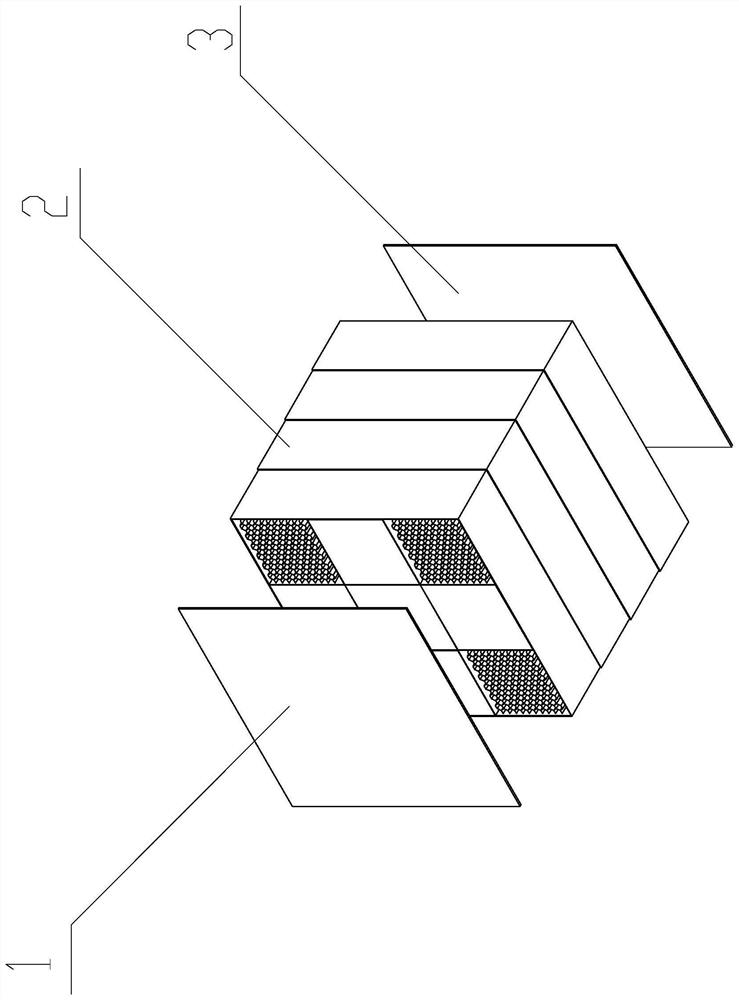

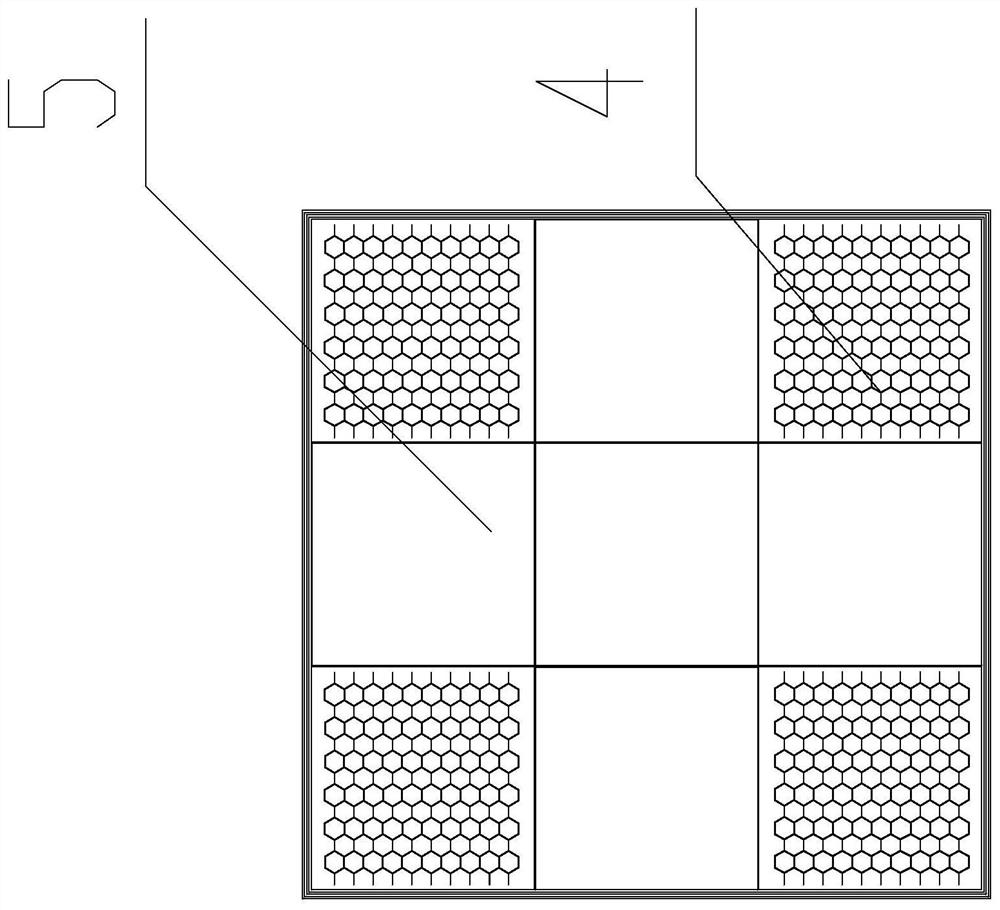

[0025] Specific implementation mode one: combine Figure 1-Figure 7 This embodiment is described. The thin-walled multicellular filled energy-absorbing structure in this embodiment includes an upper cover plate 1, a lower cover plate 3, a tube body 2 with a gradient thickness, a plurality of honeycomb blocks 4 and a plurality of foam filling body 5, a partition plate is installed in the tube body 2 with a gradient thickness, and the tube body 2 with a gradient thickness is divided into multiple spaces by the partition plate, and a plurality of honeycomb blocks 4 are installed in In a part of the space of the pipe body 2 with a gradient thickness, a plurality of foam fillers 5 are installed in another part of the space of the pipe body 2 with a gradient thickness, and the upper cover plate 1 is installed on one end of the pipe body 2 with a gradient thickness, and the lower The cover plate 3 is mounted on the other end of the tubular body 2 with a gradient thickness.

[0026] ...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination Figure 5-Figure 7 Describe this embodiment, the thin-walled multicellular filled energy-absorbing structure described in this embodiment, the tubular body 2 with a gradient thickness includes a first shell, a second shell, a third shell and a fourth shell, the fourth shell The shell, the third shell and the second shell are sequentially fitted in the first shell from the outside to the inside, and the first shell, the second shell, the third shell and the fourth shell are arranged coaxially and integrally, the first The length of the housing is greater than that of the second housing, the length of the second housing is greater than the length of the third housing, and the length of the third housing is greater than that of the fourth housing. The shape of the pipe body 2 is arranged in a stepped shape with a stepped thickness. The stiffness of the overall section of the structure increases along the direction of axial com...

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 4 Describe this embodiment, the thin-walled multicellular filled energy-absorbing structure of this embodiment also includes a plurality of partitions 6, and at least two partitions 6 are set on each honeycomb block 4, and the side of each honeycomb block 4 The distance to the inner wall of the pipe body 2 or the partition plate with a gradient thickness is 10mm. In order to reduce the influence of the pipe wall of the pipe body 2 on the honeycomb block 4, the honeycomb block 4 is made of honeycomb aluminum material, and other methods are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com