Lifting hanging bracket capable of working at night for goods lifting

A technology for night work and cargo, applied in the direction of trolley cranes, cranes, lighting applications, etc., can solve the problems of hanging the output end of the hanger on the cargo, the volume and weight of the cargo, and the unstable hanging position, etc., to facilitate disassembly and assembly. , The effect of facilitating night work and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

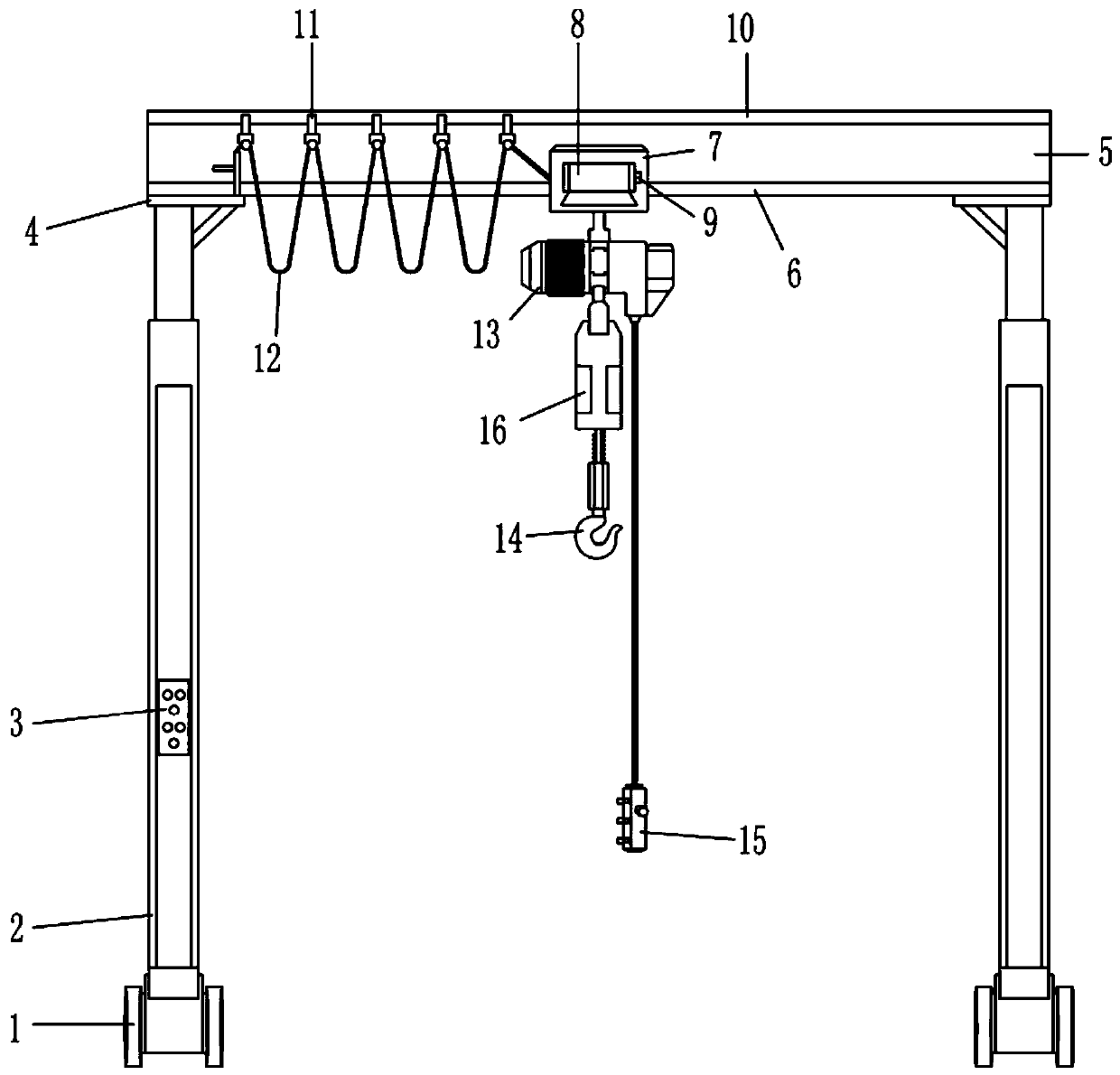

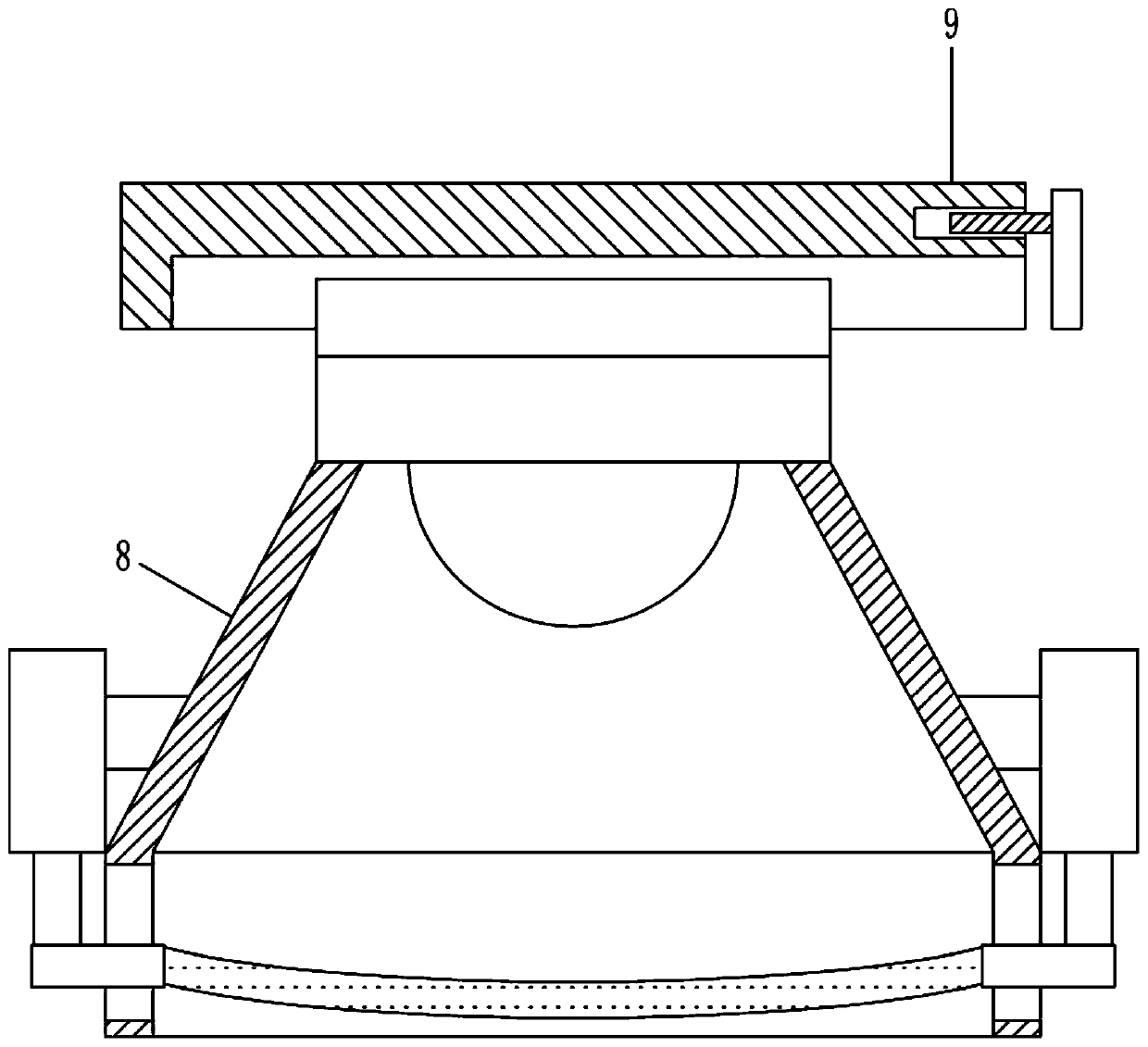

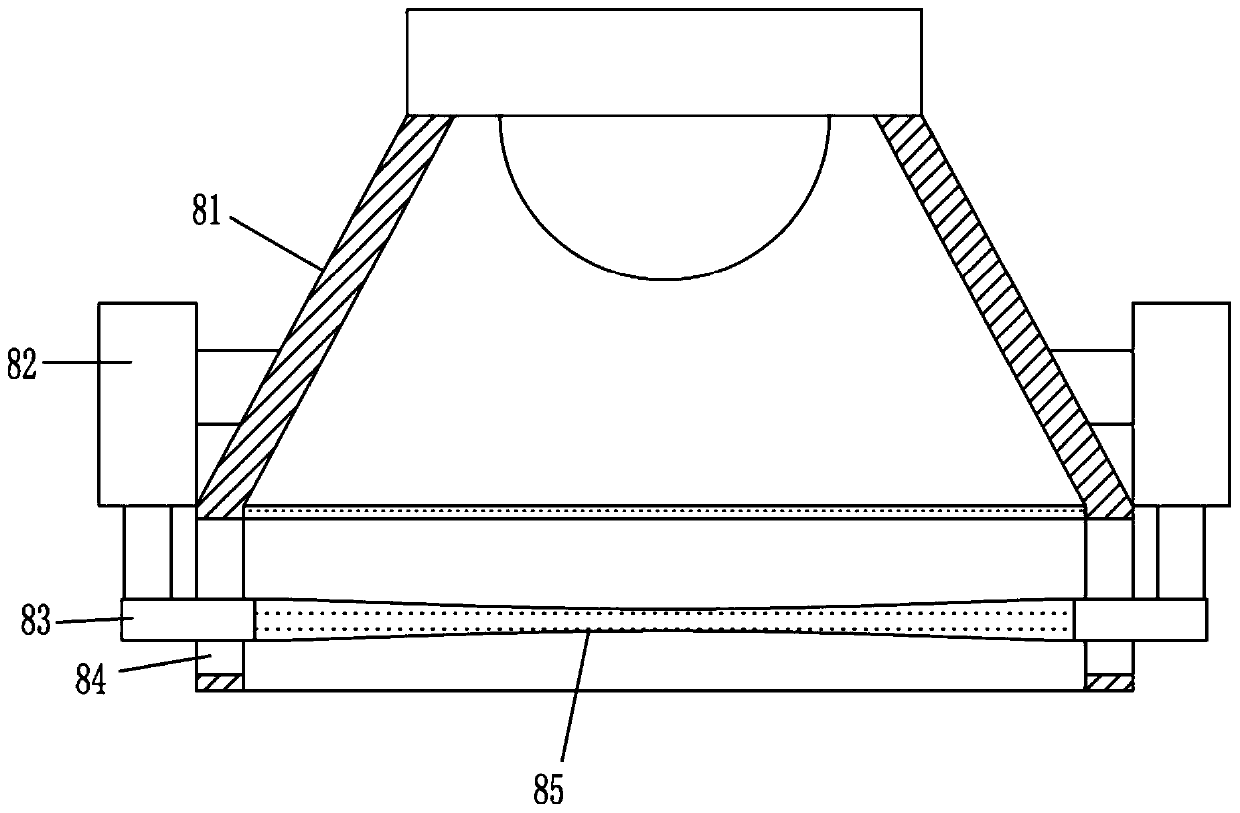

[0026] A lifting hanger that can work at night for cargo lifting, such as Figure 1-7 As shown, it includes a moving wheel 1, a telescopic frame 2, a numerical control panel 3, a load-bearing frame 4, a support frame 5, a first slide rail 6, a drive slider 7, an illumination component 8, a disassembly component 9, and a second slide rail 10 , wire 12 wheel 11, wire 12, lifting reel 13, lifting hook 14, controller 15 and balance part 16; telescopic frame 2 is fixed on the top of moving wheel 1; numerical control panel 3 is fixed on the outer wall of telescopic frame 2 The load-bearing frame 4 is connected to the output end of the telescopic frame 2 by transmission; the support frame 5 is fixedly connected to the top surface of the load-bearing frame 4; the first slide rail 6 is fixedly connected to the bottom of the support frame 5; the second slide rail 10 is fixedly connected to the top of the support frame 5 The dismounting part 9 is slidingly connected with the first slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com