Purification method for large-scale production of embryogenic antigens

A purification method and antigen technology, applied in the field of vaccine antigen preparation, to achieve the effect of improving the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Establishment method

[0028] The method established by the present invention comprises the following steps:

[0029] 1.1 Variable temperature treatment:

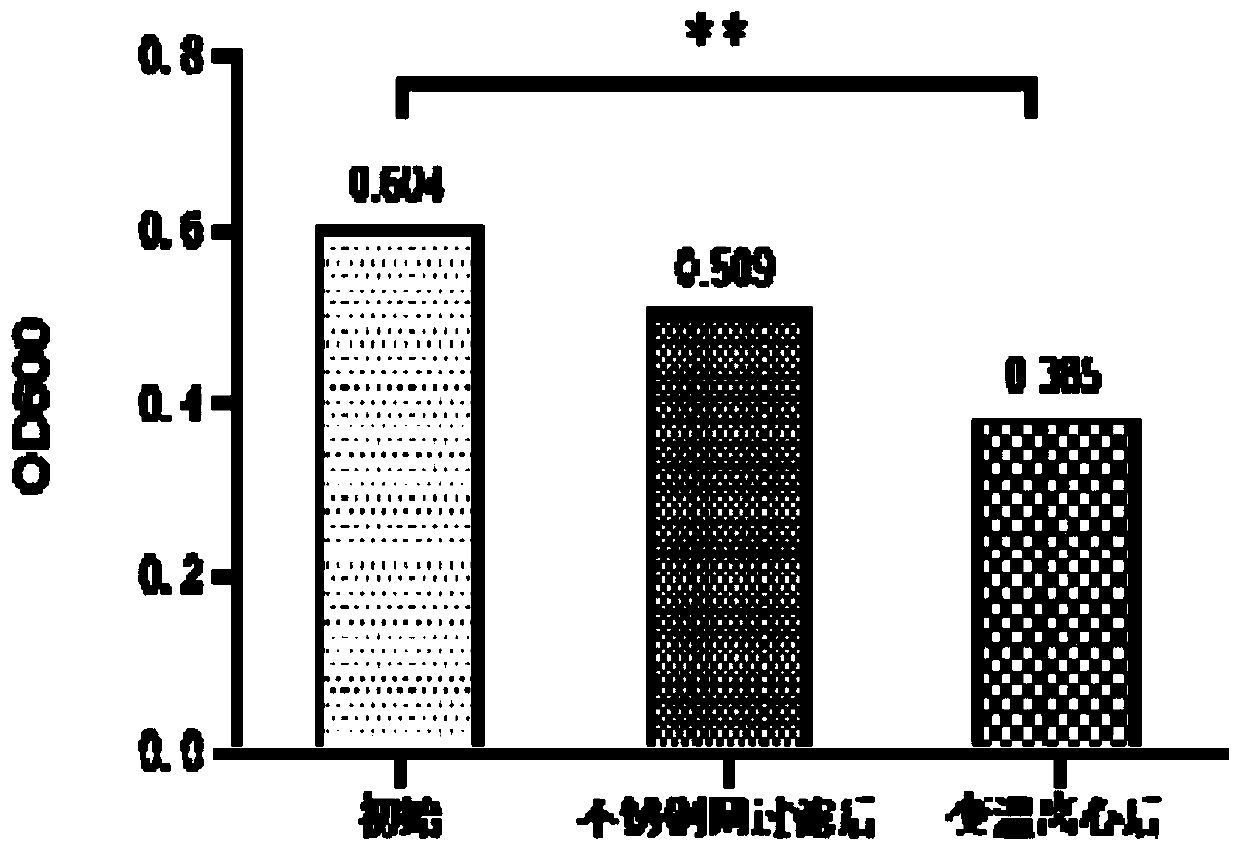

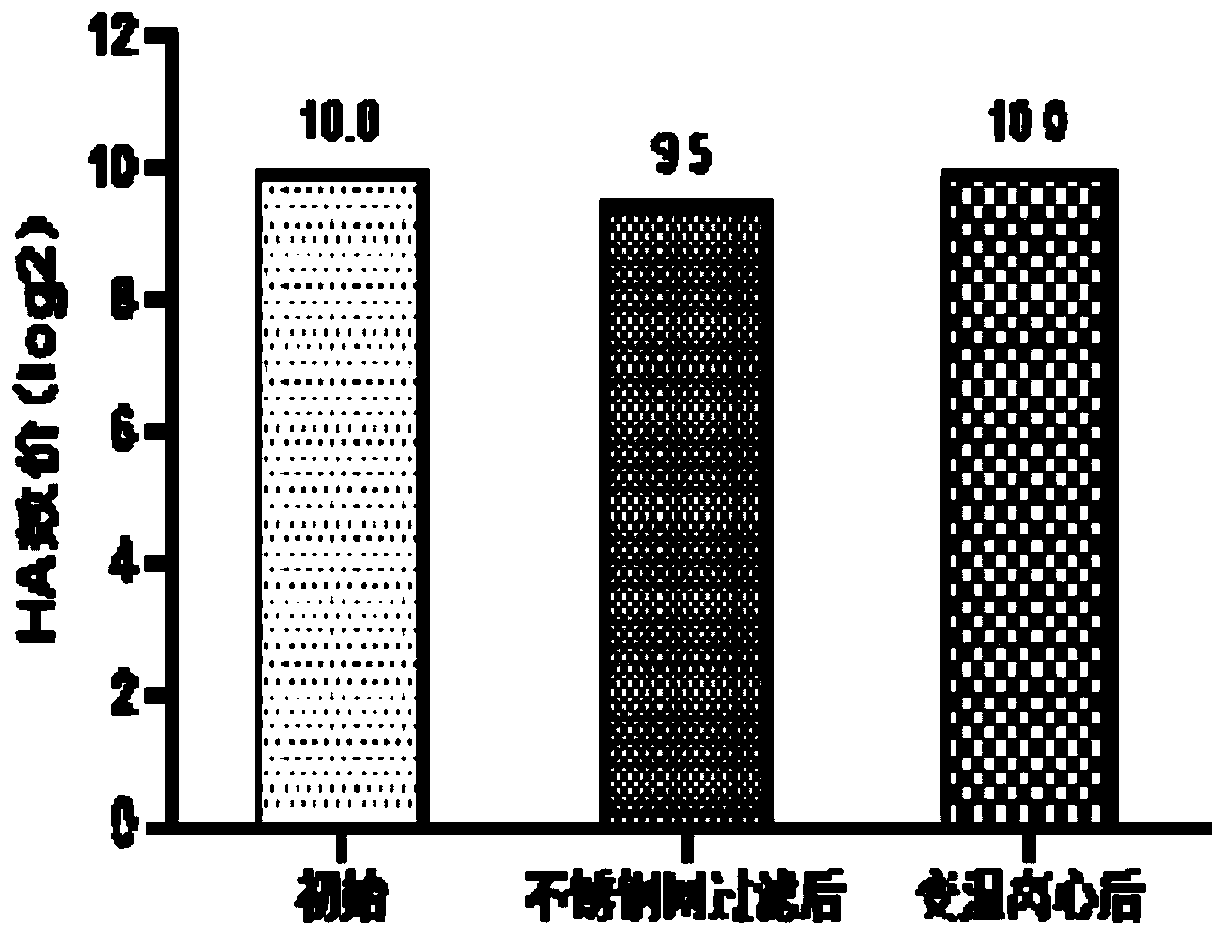

[0030] Select the inactivated antigen of the avian influenza virus H5N1 subtype Re-8 strain, the HA is 10Log2, and the turbidity OD600 value is 0.604, and it is rapidly lowered from the inactivated state of 36-37°C to 2-15°C.

[0031] Set up constant temperature, direct stainless steel mesh filter control group.

[0032] 1.2 Stand still:

[0033] Place the inactivated antigen at 2-15°C for 7-14 days. The purpose is to completely separate out the remaining miscellaneous proteins and keep them stable.

[0034] The selection of the standing date not only takes into account the removal efficiency of foreign proteins, but also avoids the loss of the target antigenic protein ( figure 1 ).

[0035] 1.3 High-speed centrifugation:

[0036] The inactivated antigen solution treated with variable temperature is...

Embodiment 2

[0039] Embodiment 2: large-scale production

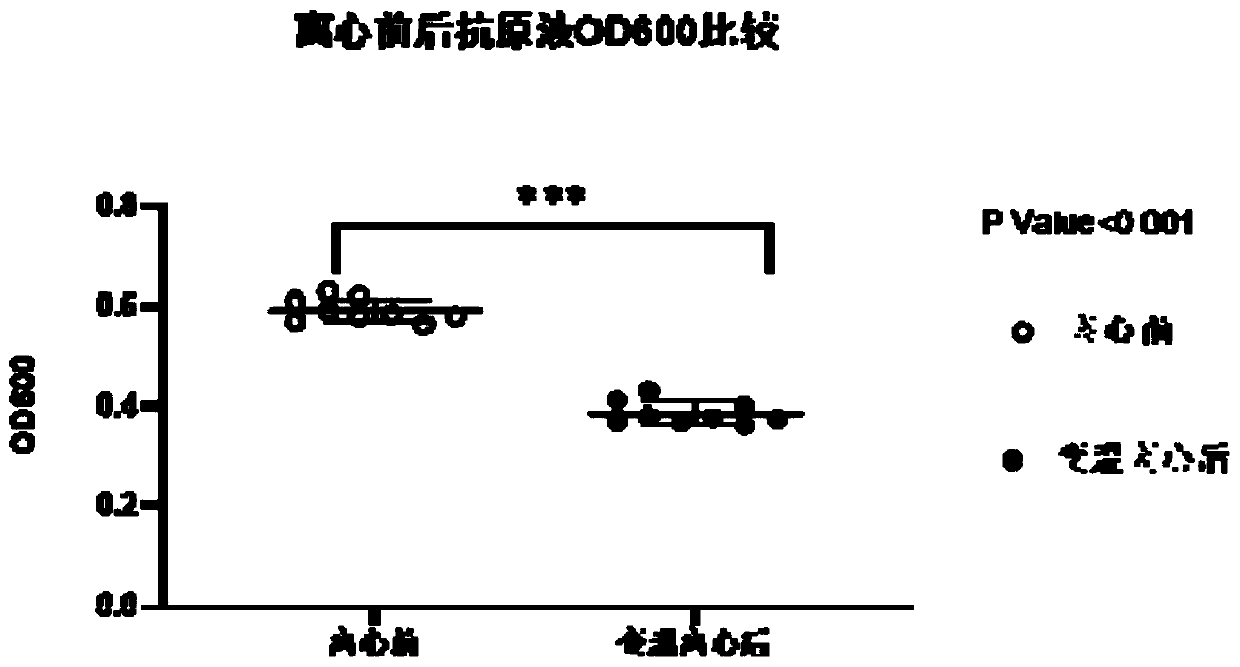

[0040] According to the method established in Example 1, the avian influenza virus H5N1 subtype Re-8 strain antigen was selected as the research object in the avian influenza inactivated vaccine workshop, and 9 batches were tried continuously, and each batch was sampled before and after the antigen was purified, and the turbidity was monitored. (OD600) and HA (see image 3 , Figure 4 ). From the monitoring data before and after centrifugation at variable temperature of 9 batches of inactivated antigens, the OD600 value dropped from 0.5 to 0.7 before centrifugation to 0.3 to 0.4 after centrifugation. There was no significant change in HA titer; indicating that the method of the present invention can be used for large-scale production applications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com