A Deviation Correction and Maintenance Method for the Smoke Guide Hole on the Roof of a Tamping Coke Oven

A technology for tamping coke ovens and smoke holes, which is used in the heating of coke ovens and coke ovens, and the mechanical treatment of coal loaded into the ovens, achieving the effects of high operating efficiency, meeting environmental protection requirements, and safe construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

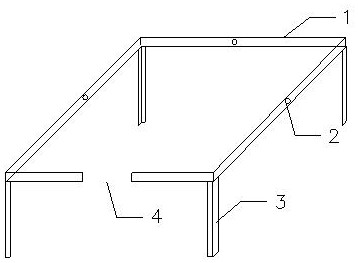

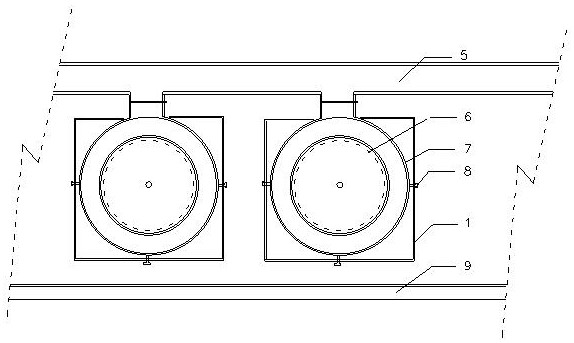

[0036] The construction process of the method for correcting and repairing the deviation of the smoke guide hole on the roof of the tamping coke oven of the present invention is as follows:

[0037] Construction preparation → smoke guide hole positioning scale, fixed bracket installation → furnace top smoke guide hole positioning and deviation displacement measurement → remove the masonry around the smoke guide hole → smoke guide hole displacement → check the smoke guide hole and smoke guide vehicle The normal bite of the smoke guide pipe → re-treatment of the root seal of the smoke guide hole and the masonry around the masonry → treatment of the water seal tank interface → garbage cleaning and unloading.

[0038] The method for correcting and repairing the deviation of the smoke guide hole on the roof of the tamping coke oven of the present invention comprises the following steps:

[0039] a. The positioning ruler is installed and fixed

[0040] In the longitudinal direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com