Biogas digester pressure-controlling and flow-collecting equipment having anti-backflow effects

A biogas digester and backflow prevention technology, applied in biochemical equipment and methods, specific-purpose bioreactors/fermenters, gas production bioreactors, etc., can solve safety hazards, pollution or safety problems, and cannot meet long-distance Conveying problems such as the operation of biogas generators to ensure normal use and prevent high-voltage risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

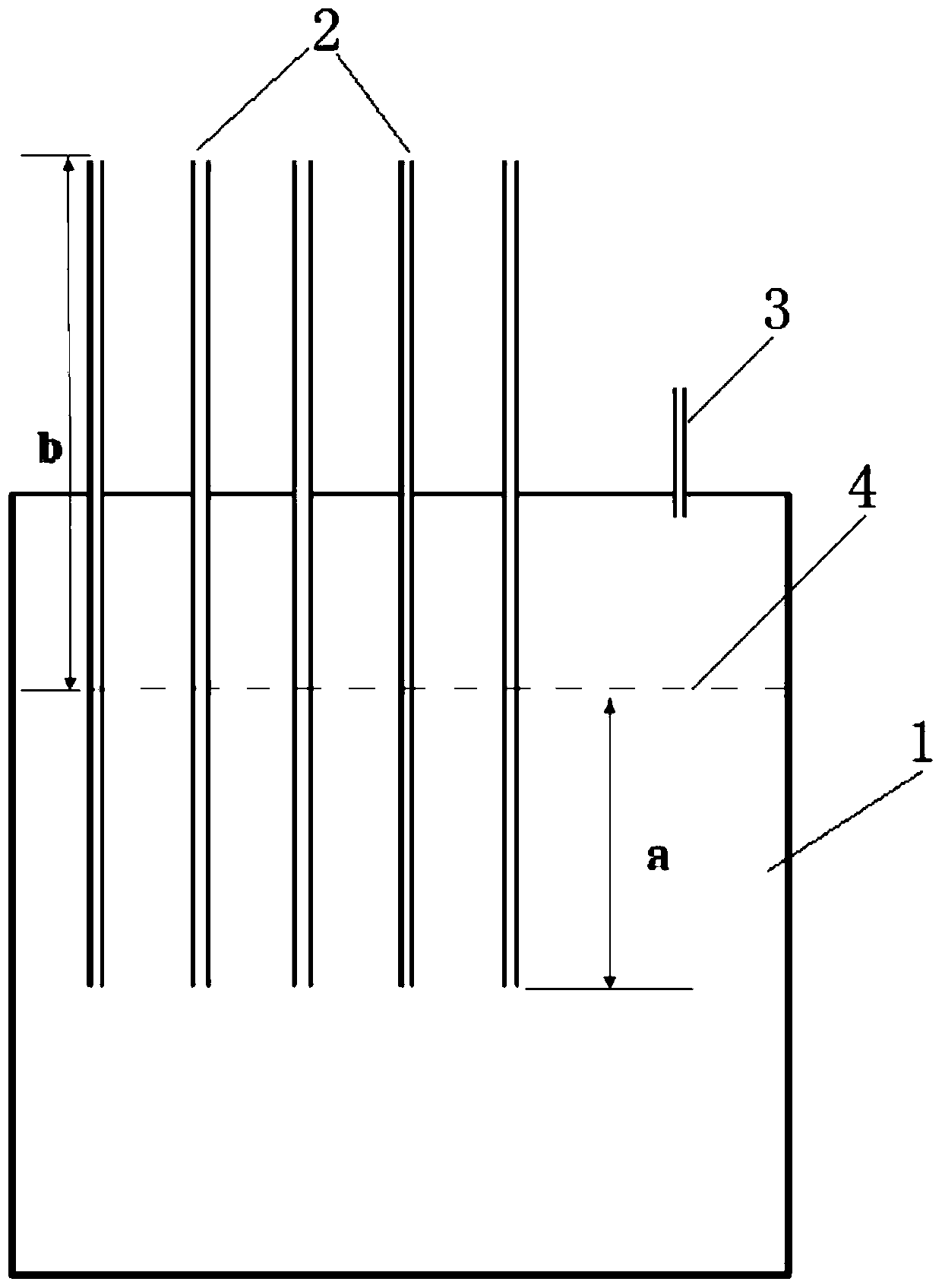

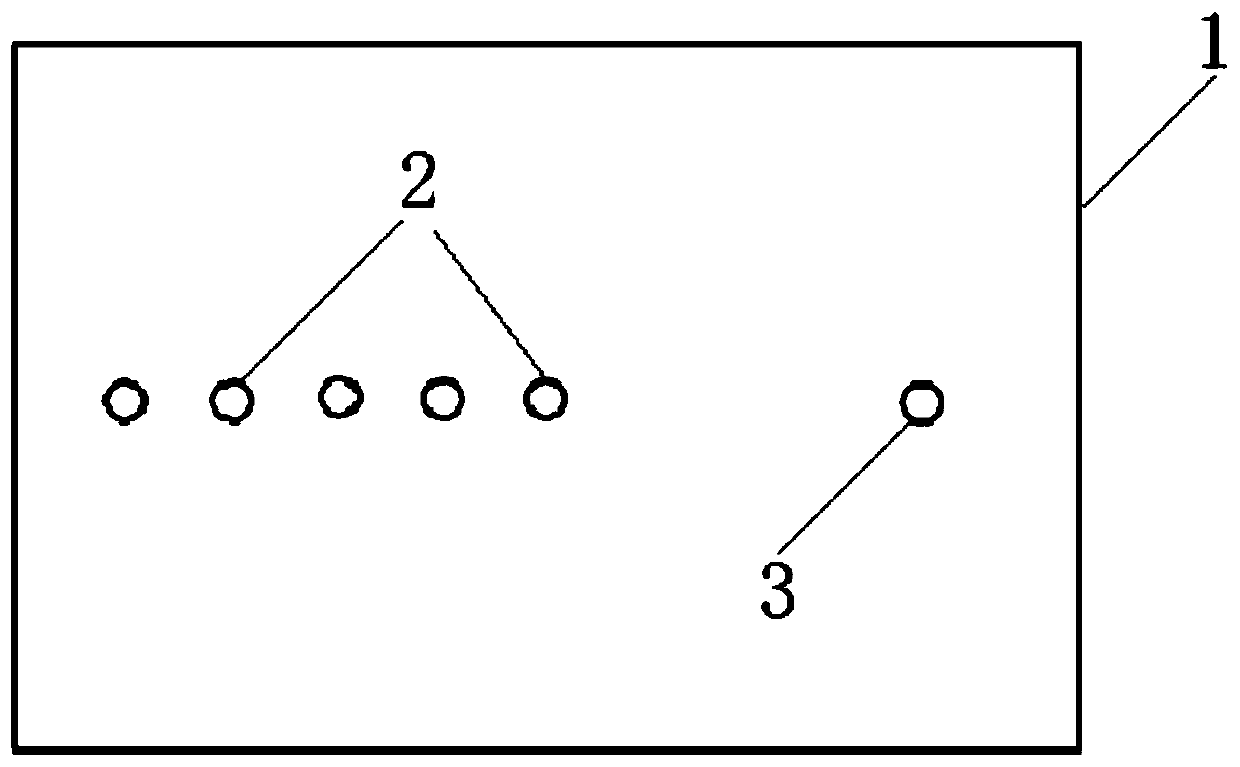

[0035] first embodiment ,refer to figure 1 and 2 , an example of a biogas digester pressure control and flow collection device with anti-reflux function designed in the present invention, including: a cavity 1, an air inlet pipe 2, an air outlet pipe 3, and a liquid (water) 4; wherein, several of the air inlet pipes 2 and at least one air outlet pipe 3 are fixed on the top surface of the cavity 1, the cavity 1 is provided with a liquid 4, and one end of the air inlet pipe 2 is located below the liquid level 4 in the cavity, that is, the air inlet pipe 2 is inserted For the part a of the liquid, the other end of the air inlet pipe 2 is located above the liquid surface 4, that is, the part b above the liquid surface of the air inlet pipe is used to introduce the gas in the biogas digester. One end of the gas outlet pipe 3 is located above the liquid surface 4, and the other end Located outside the cavity, the gas outlet pipe 3 is mainly used to lead out the gas (such as bioga...

no. 2 example

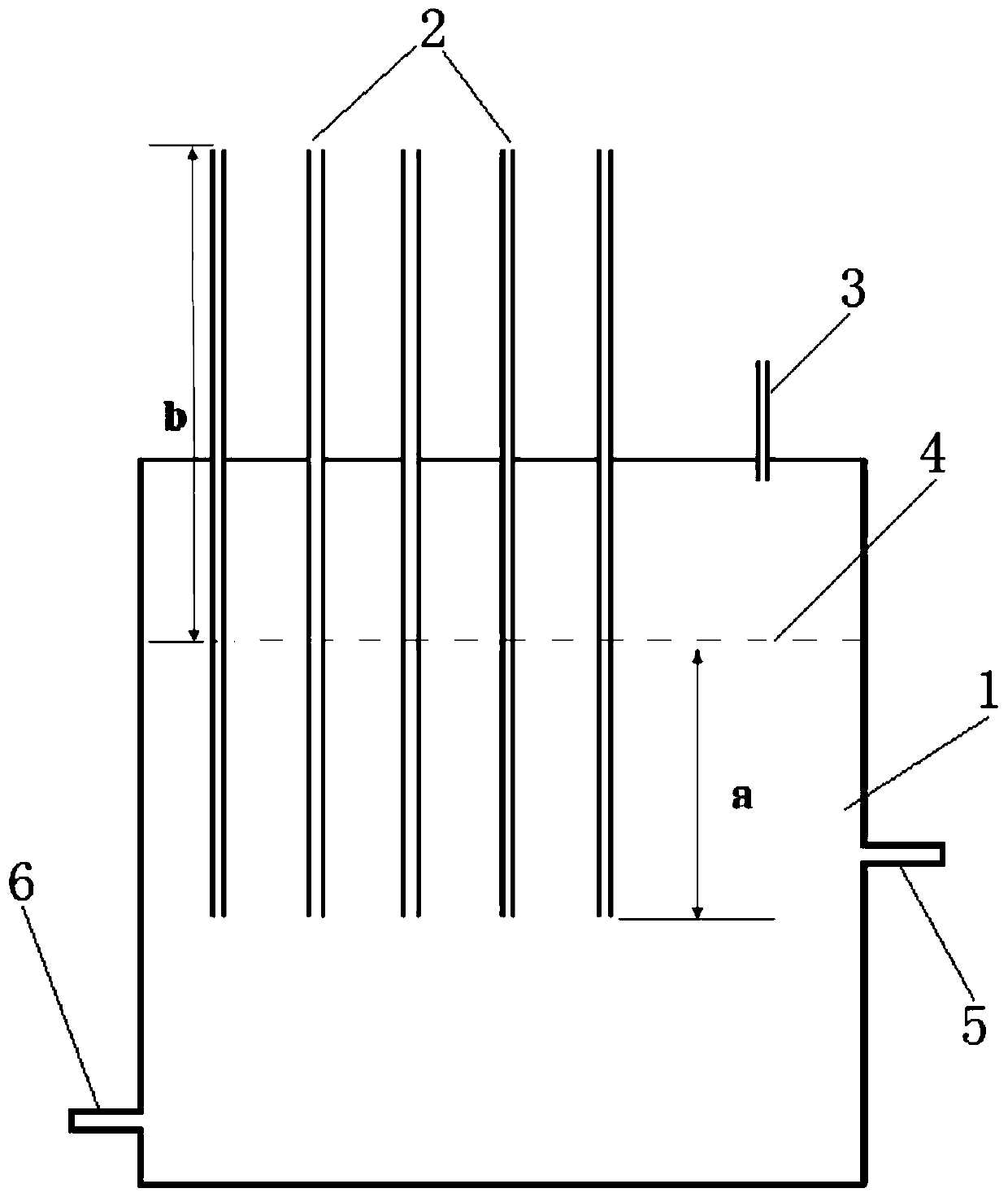

[0043] second embodiment , continuing to refer to the first example and image 3 , the cavity 1 is also provided with a liquid inlet 5 and a liquid outlet 6 to facilitate the replacement of the liquid in the cavity 1, but the water inlet and the water outlet need to be in a closed state when the device is running.

no. 3 example

[0044] third embodiment , continuing to refer to the first example and image 3 , in order to facilitate the use of flowing liquid in the cavity 1, the cavity 1 is also provided with a liquid inlet 5 and a liquid outlet 6. During use, it is necessary to ensure that the liquid level in the cavity 1 changes within a set range, To keep the liquid level in the intake pipe stable, to ensure the stable pressure in the biogas digester connected to cavity 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com