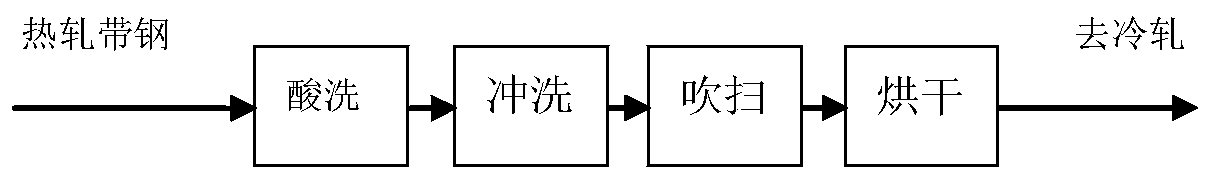

Method for eliminating shutdown scale in cold-rolling pickling process section

A process section and pickling technology, which is applied in the field of cold-rolled pickling, can solve the problems of parking rust and other problems, and achieve the effect of eliminating parking rust, high economic benefits, and reducing average annual economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

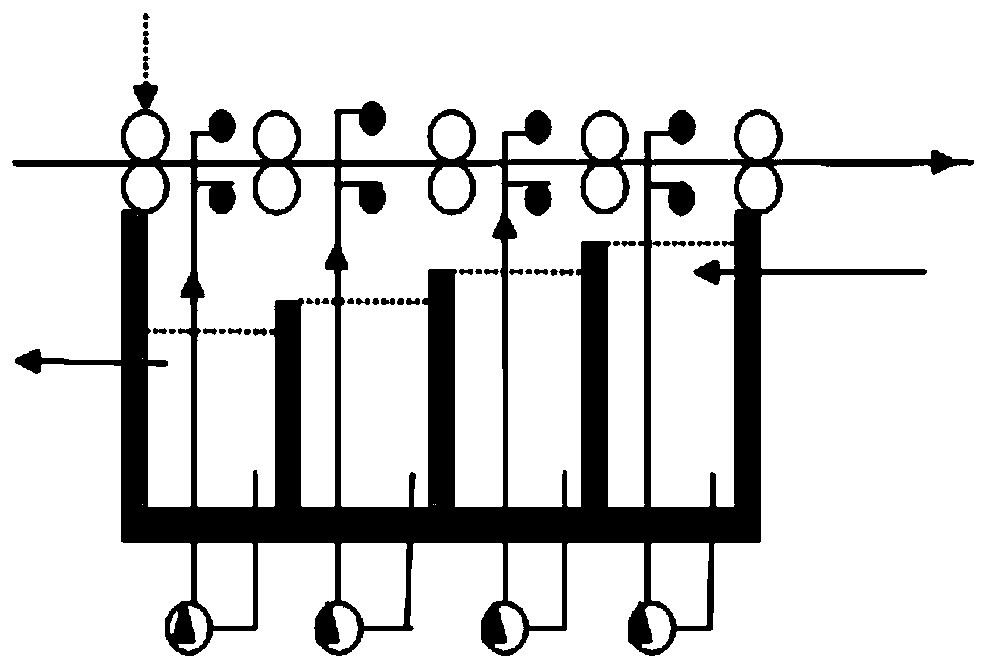

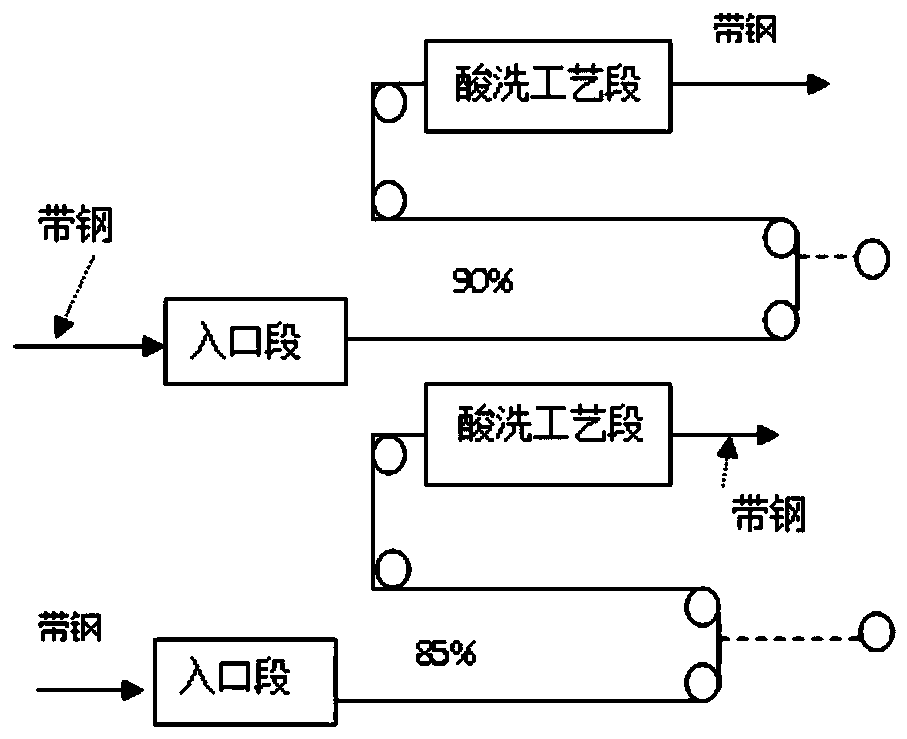

[0042] Such as image 3 As shown, a specific operation method for eliminating water rust in the cold-rolling pickling process section is:

[0043] First add the joint inching switch of the pickling process section in the operating table, and then install a reverse flushing system 2 before the pickling tank 1 of the cold rolling pickling process section. After the reverse flushing system is installed, follow the steps below ,

[0044] (1) After a long period of shutdown, fill the pickling tank 1 with acid liquid;

[0045] (2) Move the "pickling process section joint inching" switch in the operating table to the back;

[0046] (3) The upper rollers of the first squeezing roller 2 (1) and the second squeezing roller 2 (2) of the reverse washing system 2 are dropped; the reverse washing system jet pump 2 (3) starts to start washing the strip; reverse The primary purging device 2 (4) and the secondary purging device 2 (5) of the flushing system are activated to start purging the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com