Trapezoid floating breakwater with waste tires

A floating breakwater and waste tire technology, applied in the field of marine engineering, can solve the problems of unstoppable waves and currents, shallow draft, etc., and achieve the effects of improving the additional quality of heave, reducing the amount of passing waves, and improving the wave absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described below through specific examples, but the present invention is not limited thereto.

[0050] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

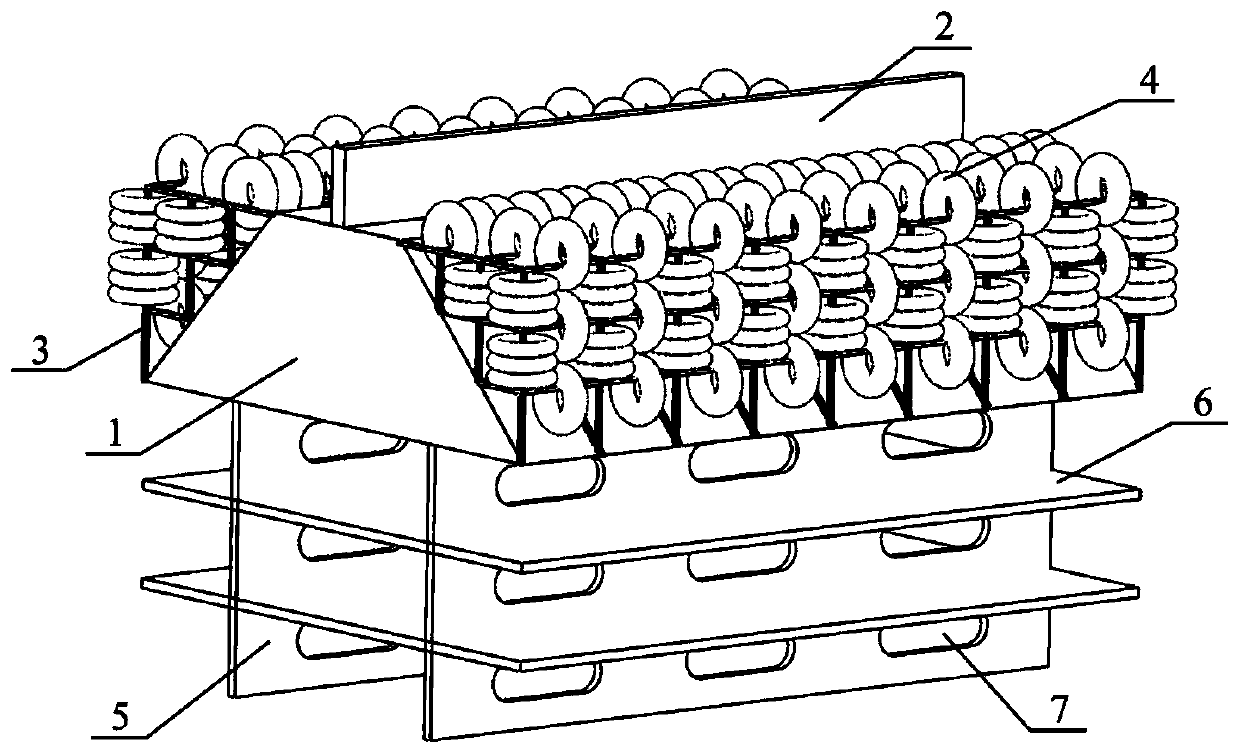

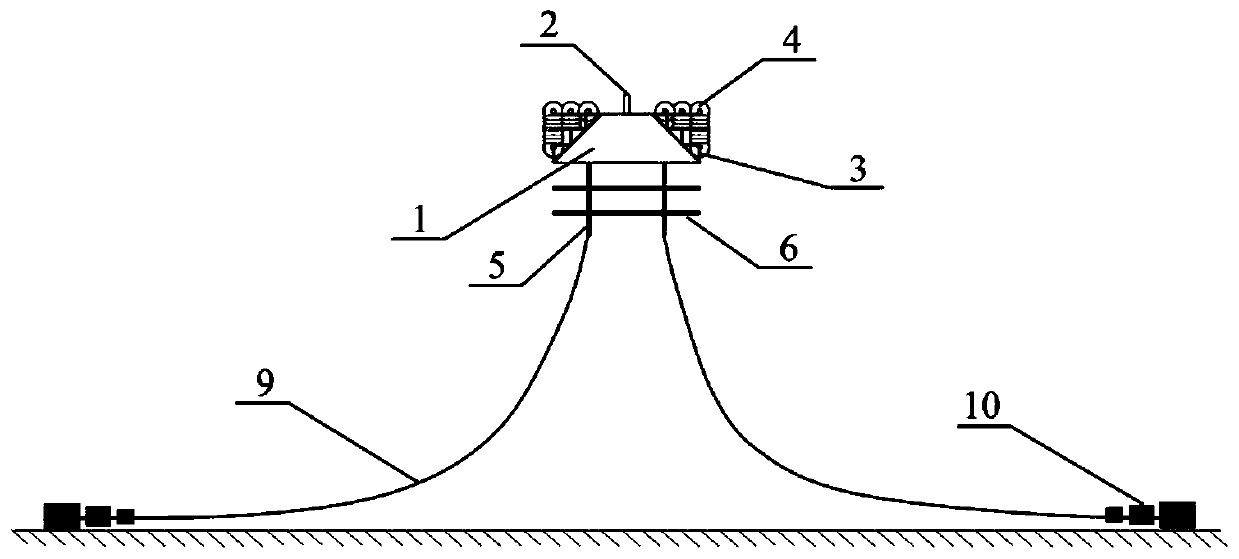

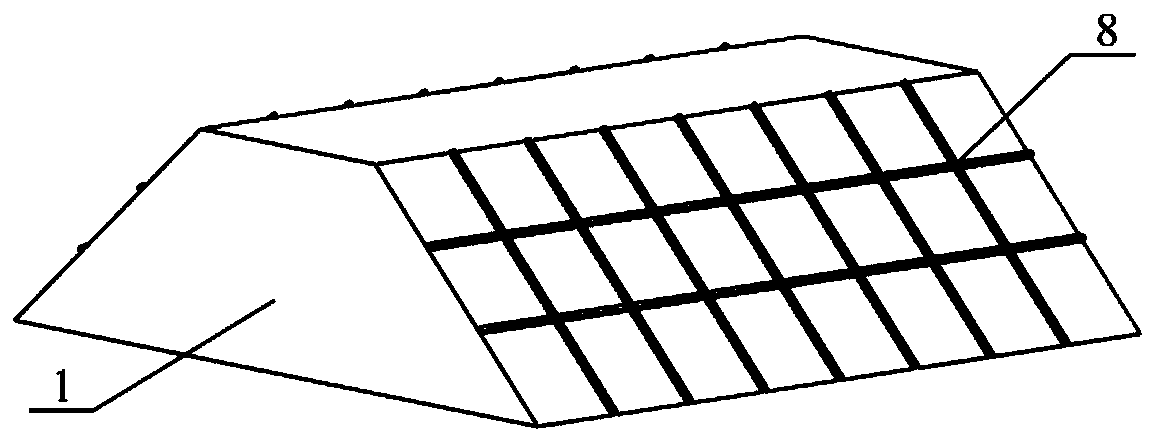

[0051] Such as Figure 1 to Figure 5 As shown, a trapezoidal floating breakwater with waste tires of the present invention includes a breakwater body 1, a wave wall 2, a truss 3, several waste tires 4, vertical plates 5, heave plates 6, and grids 8 and an anchoring system, the anchoring system includes a mooring chain 9 and a counterweight 10.

[0052] In this embodiment, the breakwater body 1 is made of rigid materials such as reinforced concrete, and has an isosceles trapezoidal cross-section. Such a shape setting can not only reflect certain incident waves, but also cause some waves to climb along the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com