Bearing driving device used for vehicle sliding plug door

A driving device and vehicle technology, which is applied in the field of rail transit, can solve the problems of difficult installation and debugging, long mechanism length, and large space occupation, and achieve the effects of eliminating height difference, reducing instantaneous resistance, and occupying small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

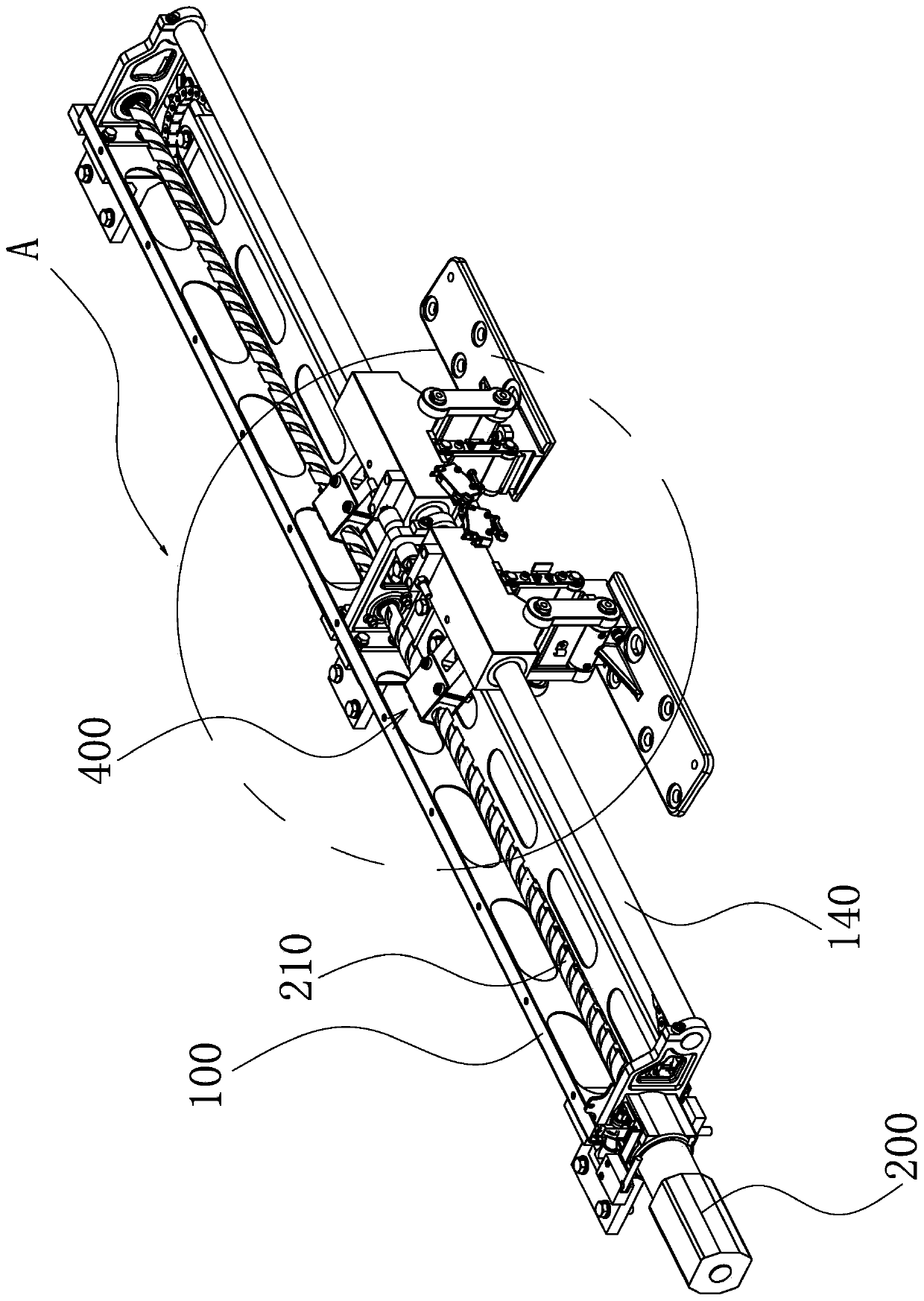

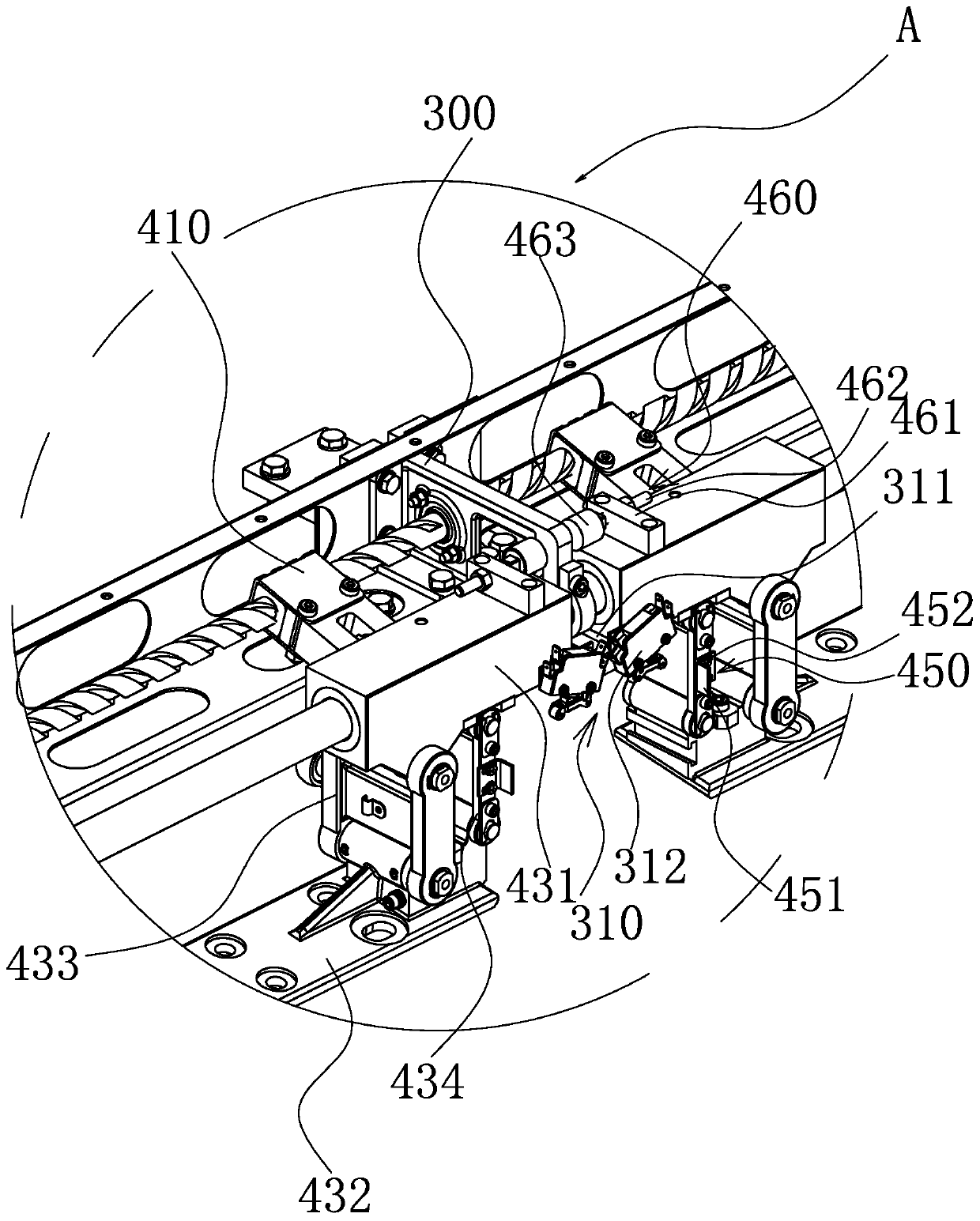

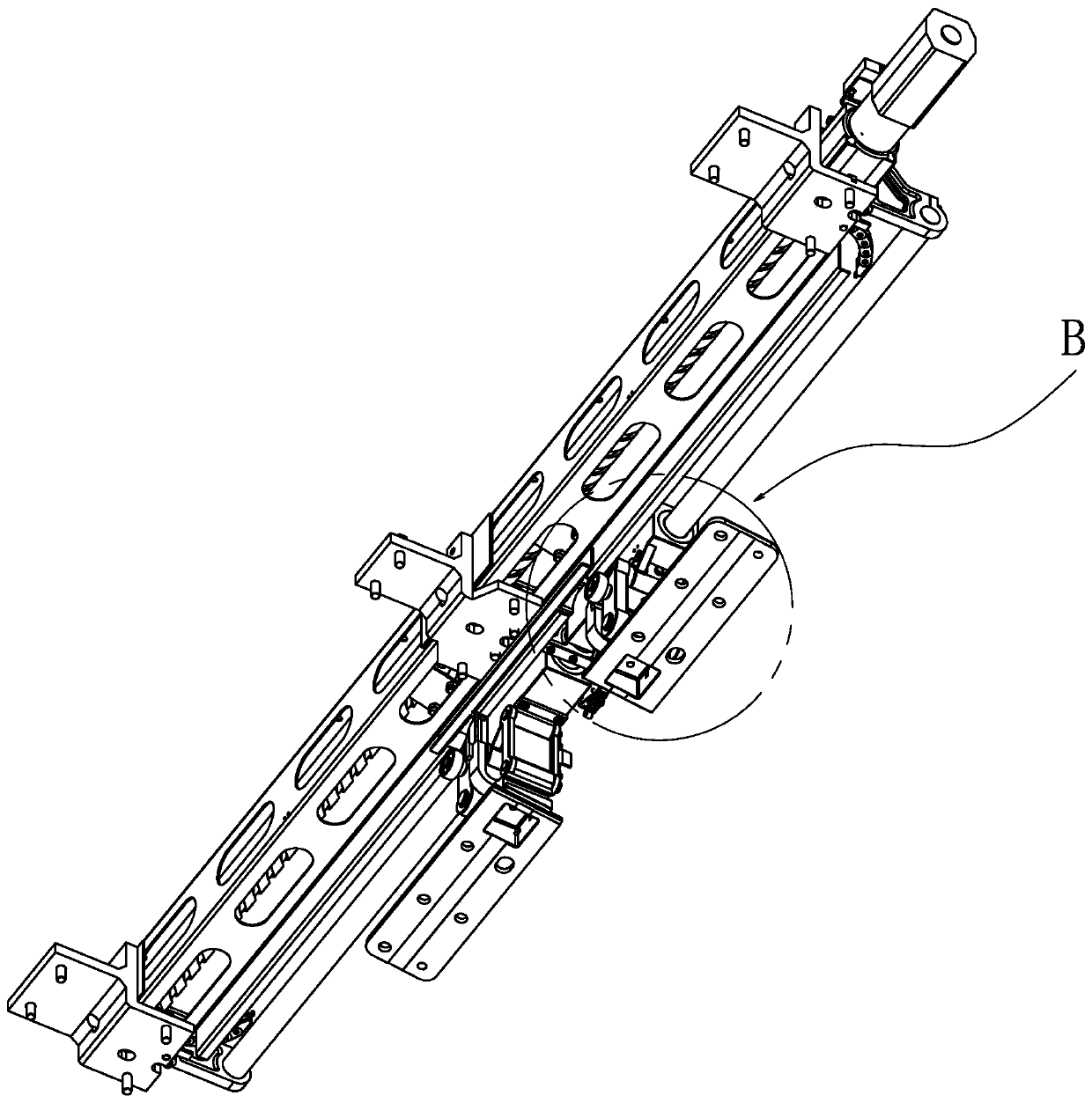

[0035] like Figure 1 to Figure 5 As shown, a load-carrying drive device for a vehicle sliding door provided by the present invention includes: a frame 100 as a carrier, wherein two first triggering parts 110 are arranged on the frame 100; a motor 200 is installed At one end of the frame 100, wherein the output end of the motor 200 is connected to a transmission part 210; the hanger 300 is located between the two first trigger parts 110, wherein one end of the hanger 300 is installed on the frame 100, The other end of the hanger 300 is equipped with two symmetrical second trigger parts 310; two transmission mechanisms 400 are respectively located on both sides of the hanger 300, and one end of each transmission mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com