Display panel and manufacturing method of display panel

A technology for display panels and manufacturing methods, which is applied in the fields of nonlinear optics, instruments, optics, etc., and can solve the problems of reduced reliability of display panels and poor sealing ability of frame glue for water vapor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

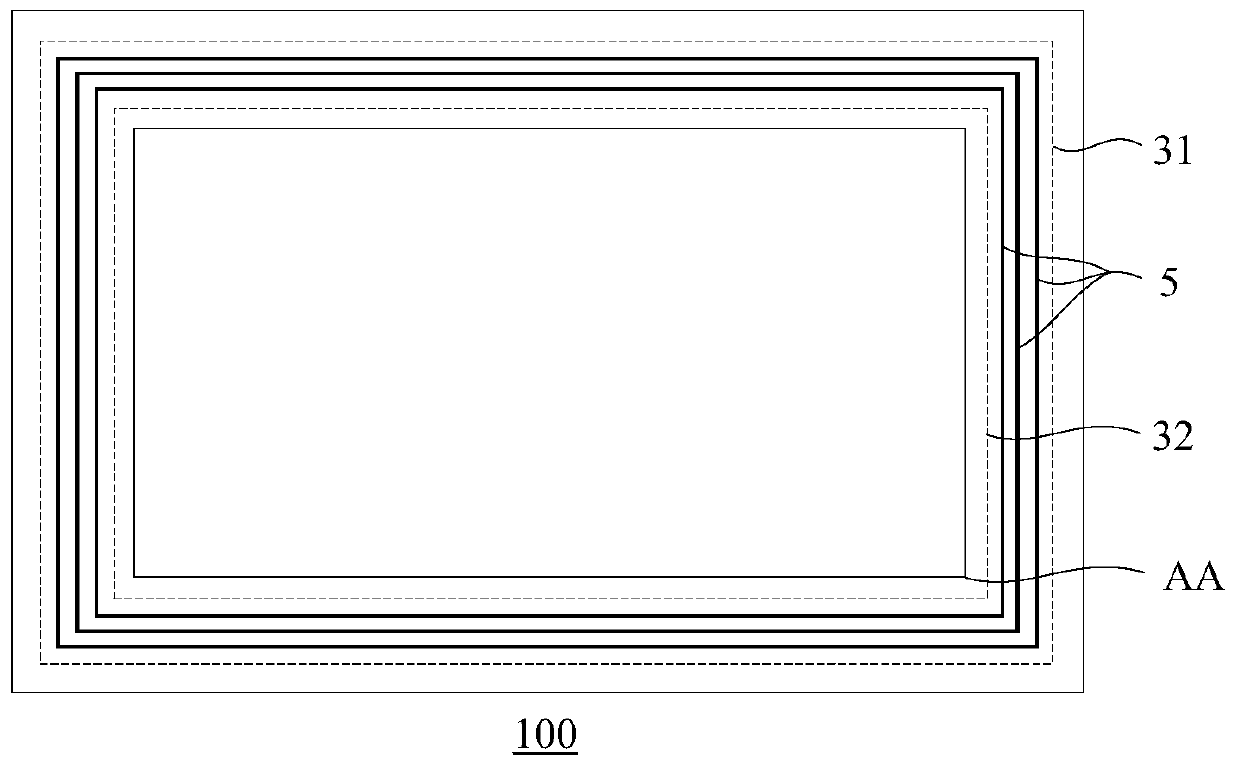

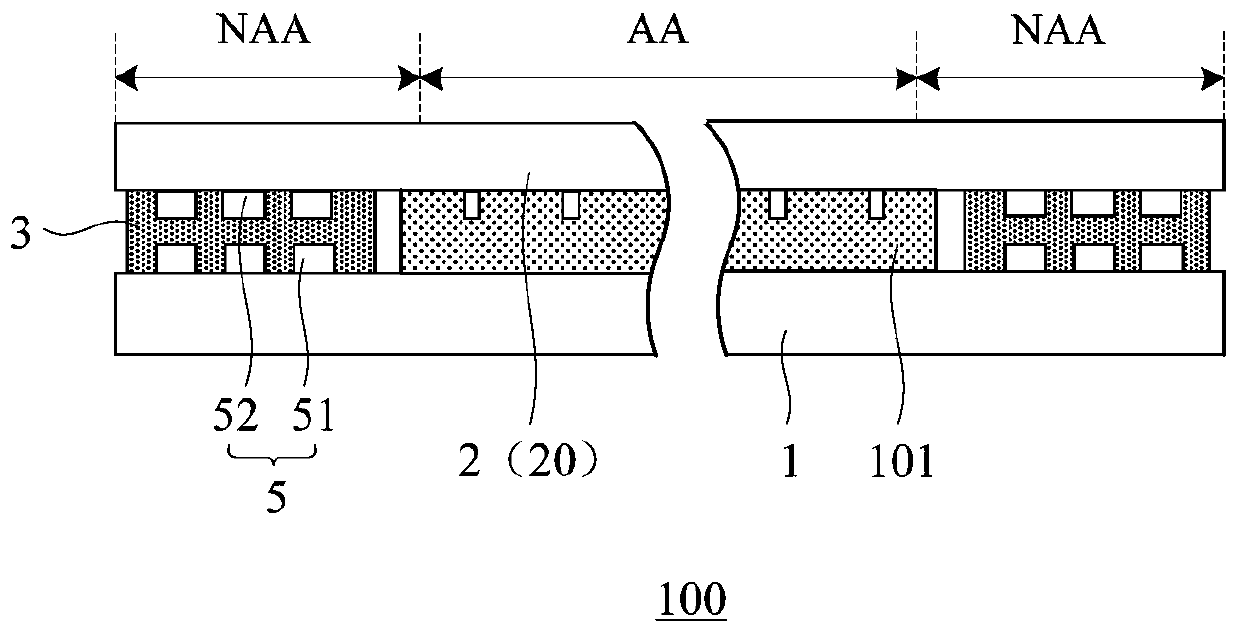

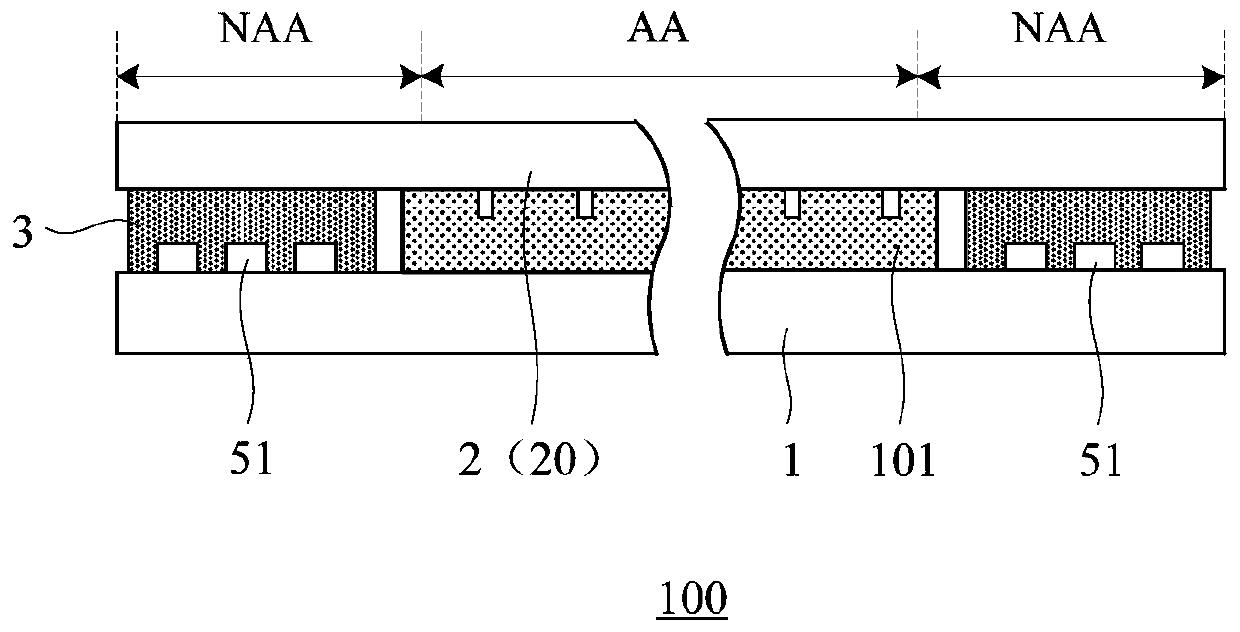

[0060] figure 1 A top view of the display panel provided by Embodiment 1 of the present invention; figure 2 It is a cross-sectional view of the display panel provided by Embodiment 1 of the present invention. Such as figure 1 , 2 As shown, the display panel 100 of the embodiment of the present application includes: an array substrate 1 and an opposite substrate 2 arranged oppositely, and a frame glue 3 interposed and attached between the array substrate 1 and the opposite substrate 2 . Wherein, the surface of the opposite side substrate 2 facing the frame glue 3, and / or, the surface of the array substrate 1 facing the frame glue 3 has a concave-convex structure 5.

[0061] In the above solution, the area where the concave-convex structure 5 is provided on the array substrate 1 and / or the opposite substrate 2 is filled with the frame glue 3 , and moisture in the outside world wants to pass through the gap between the frame glue 3 and the array substrate 1 and / or the opposit...

Embodiment 2

[0125] Figure 10 It is a schematic flowchart of the manufacturing method of the display panel provided by Embodiment 2 of the present invention. Such as Figure 10 As shown, this embodiment provides a method for manufacturing a display panel, and the method for manufacturing a display panel in this embodiment is used to manufacture the display panel described in Embodiment 1. The specific structure and principle of the display panel have been described in detail in Embodiment 1, and will not be repeated here.

[0126] As mentioned in the description of the display panel in Implementation 1, the display panel of this embodiment includes an array substrate and an opposite substrate, and a frame glue interposed and attached between the array substrate and the opposite substrate.

[0127] The manufacturing method of the display panel of this embodiment includes:

[0128] S10, forming a concave-convex structure on at least one of the surface of the opposite substrate facing the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com