Simulation method of plate-fin heat exchanger

A technology of heat exchanger and simulation method, applied in design optimization/simulation, instrumentation, electrical digital data processing, etc., to achieve the effect of reducing experimental work and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with drawings and embodiments.

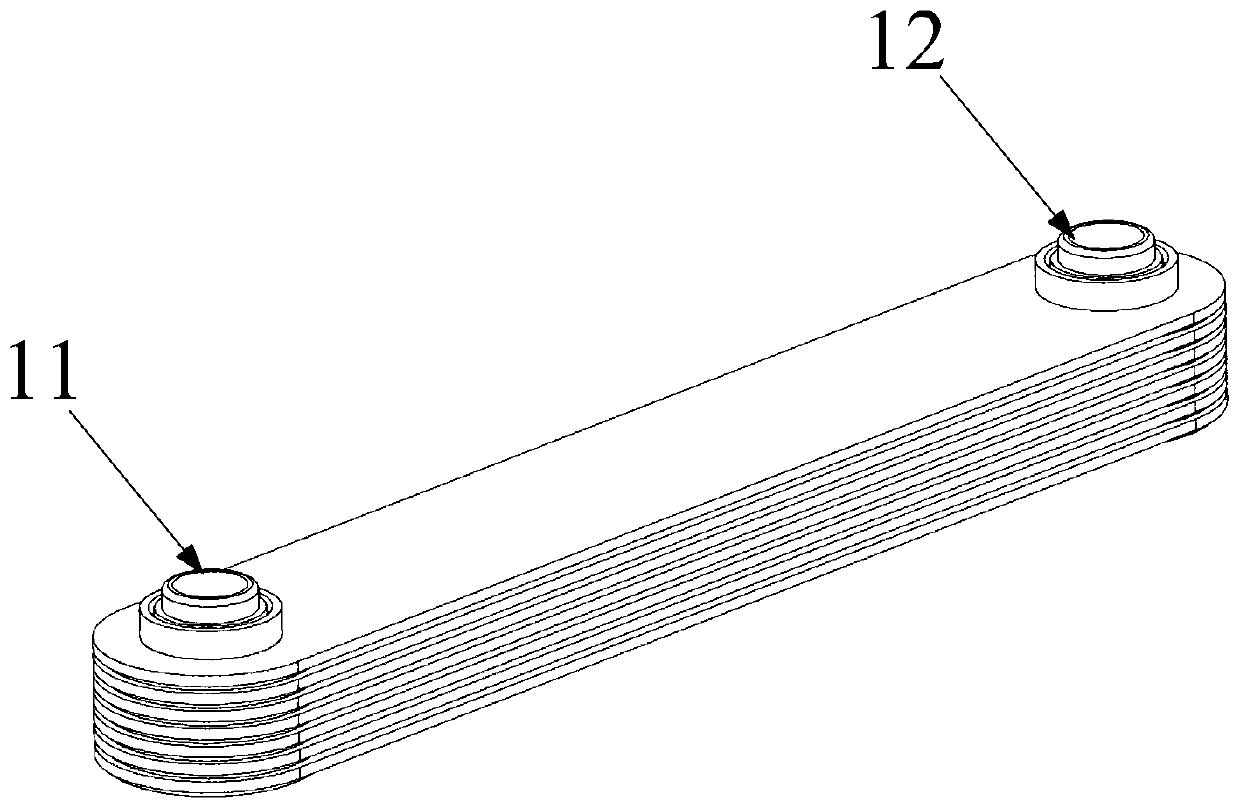

[0057] The invention provides a simulation method of a plate-fin heat exchanger, which can accurately consider the influence of fluid velocity and temperature changes in different heat dissipation channels on heat transfer, and provides a technical solution for the performance prediction of the plate-fin heat exchanger , to improve thermal simulation accuracy.

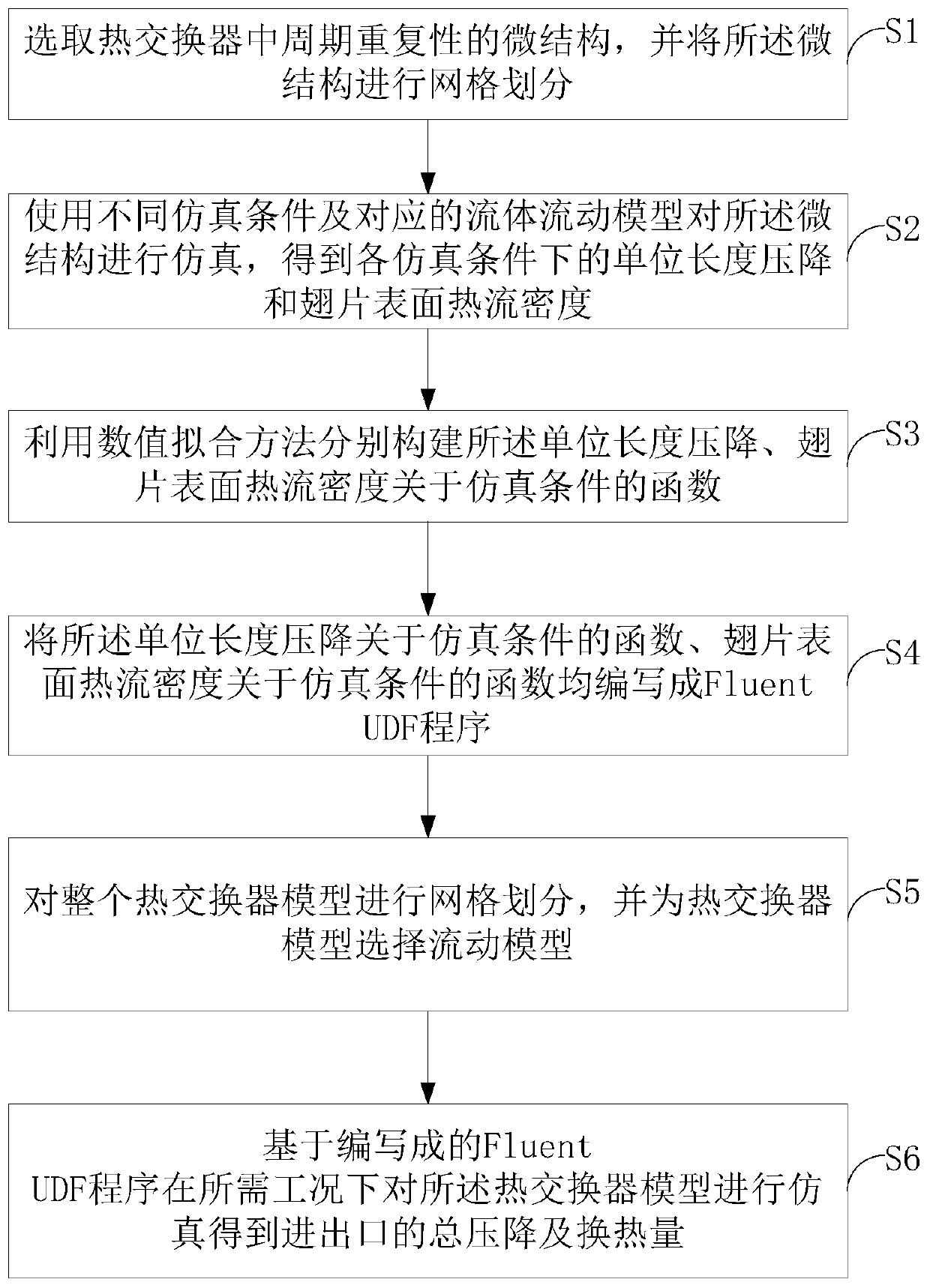

[0058] see figure 1 , a simulation method for a plate-fin heat exchanger, comprising:

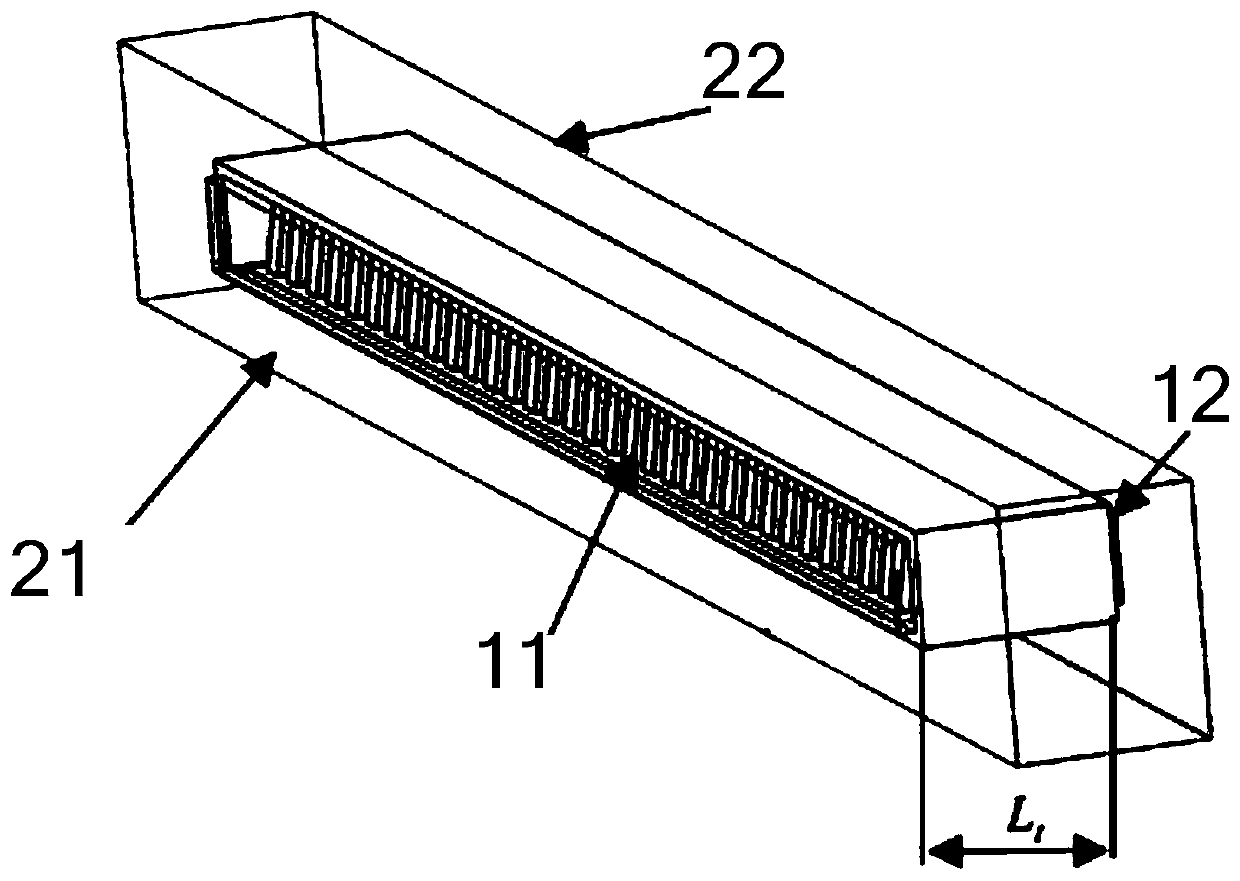

[0059] S1, select the periodically repeating microstructure in the heat exchanger, and divide the microstructure into grids; select the representative periodic repeating microstructure in the heat exchanger, which is beneficial to reduce the number of grids and the calculation time cost ; When dividing the grid, the height of the first layer grid should be determined according to the specific working conditions, and the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com