Anti-blocking push rod device, working method and vending machine

A push rod device, anti-jamming technology, which is applied in the directions of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc. Easy to get stuck, long waiting time for maintenance personnel, low efficiency, etc., to achieve the effect of improving fluency and safety, improving efficiency and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In a typical implementation of the present disclosure, such as Figure 1-Figure 6 As shown, an anti-jamming type push rod device is proposed.

[0040] Aiming at the problem that the product is stuck when the vending machine is shipped, in order to improve the efficiency of this type of troubleshooting, improve the shopping experience of consumers, and reduce the maintenance frequency of the vending machine by the maintenance personnel, it is necessary to set up corresponding settings for the vending machine. Anti-jamming mechanism, use the anti-jamming mechanism to determine and solve the problem of cargo jamming in time.

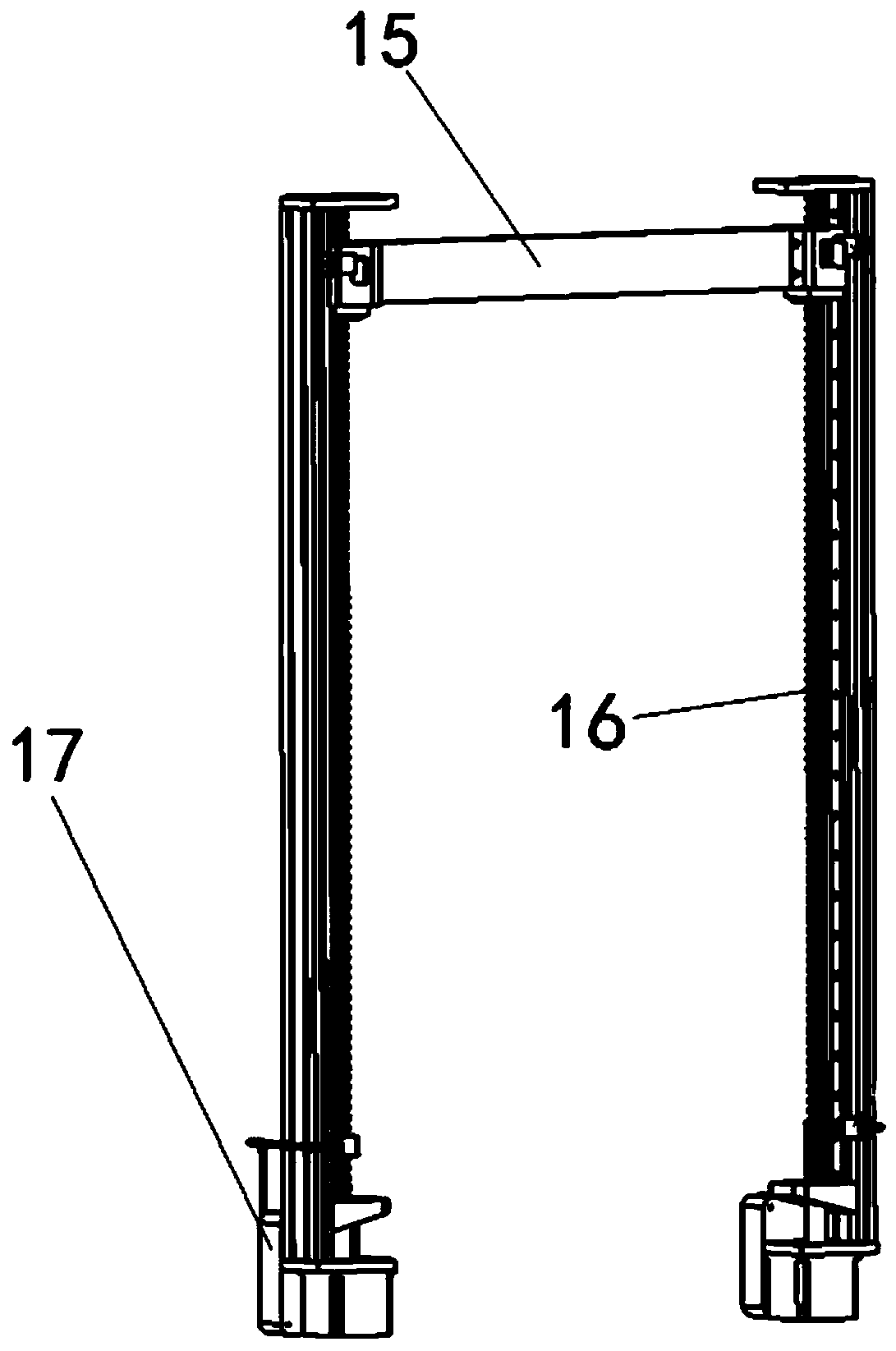

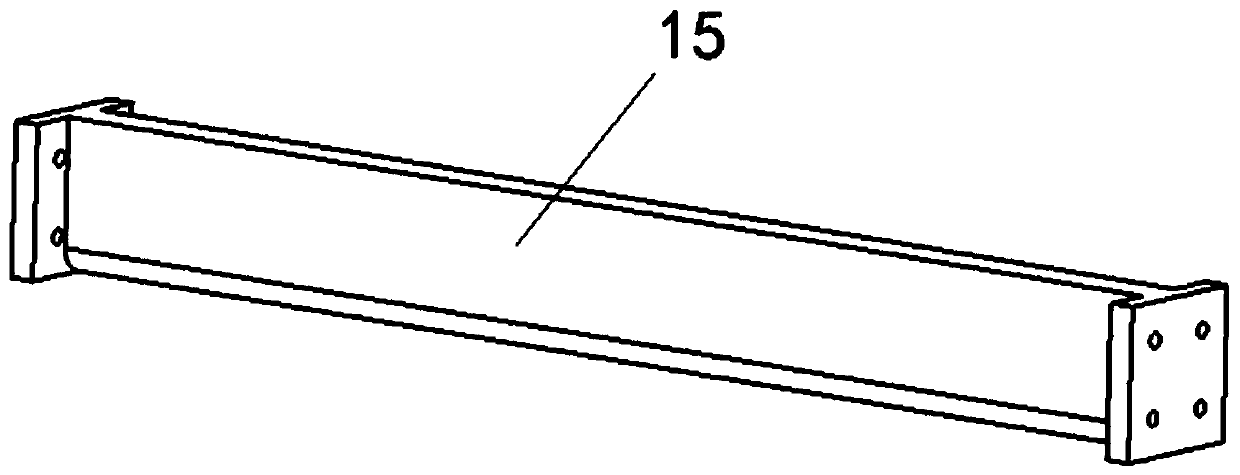

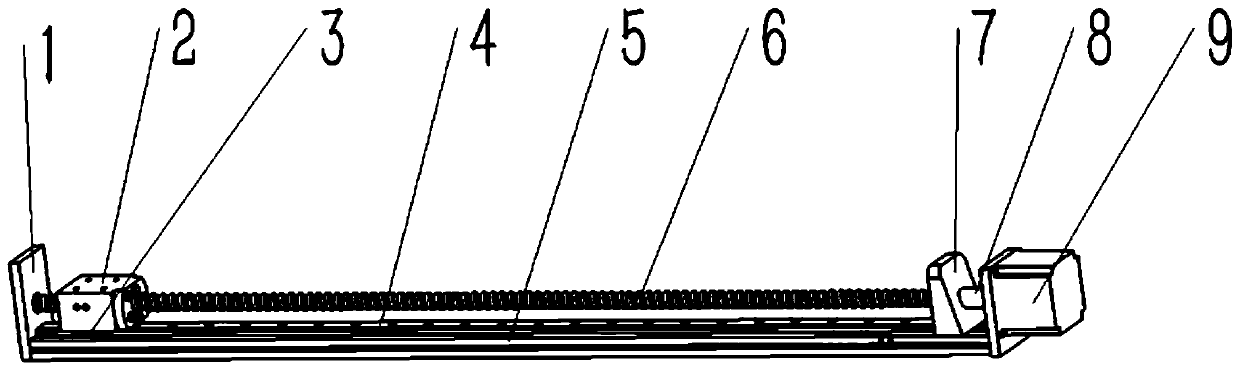

[0041] In this embodiment, an anti-jamming push rod device is provided, including a push rod 15 and a detection module 14. The push rod is equipped with a kinematic pair and a drive mechanism 17, and the push rod moves along the kinematic pair under the drive of the drive mechanism. Reciprocating motion, the detection module is used to detect whethe...

Embodiment 2

[0062] In another typical embodiment of the present disclosure, as Figure 1-Figure 6 An anti-jamming push rod working method is provided, using the anti-jamming push rod device as described in Embodiment 1.

[0063] Take the following steps:

[0064] When the anti-jamming push rod device inside the vending machine is on standby, the push rod 15, the moving slider 2 and the guide slider 3 are located at the upper proximity switch 10;

[0065] The controller is electrically connected with the main controller of the vending machine, and obtains the shipping information of the goods from the main controller. After the vending machine is shipped from the material channel, the detection module detects whether the goods have fallen to the delivery port;

[0066] If the goods fail to drop to the delivery port, the detection module 14 sends a signal, and the drive mechanism 17 sends a forward rotation command to the motor 9 after receiving the signal directly or through the controlle...

Embodiment 3

[0073] In yet another exemplary embodiment of the present disclosure, such as Figure 1-Figure 6 As shown, a vending machine is provided, which utilizes the anti-jamming push rod device as described in Embodiment 1.

[0074] The anti-jamming push rod device is installed inside the vending machine, and the lead screw slider mechanism is installed on both sides of the material channel area of the vending machine. The push rod covers the entire material channel area in the transverse direction, and the When moving back and forth, it can cover the falling path of the product, so that when the product is stuck during the falling process, the push rod can move to this position for troubleshooting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com