PVC sliding contact line rail extrusion die for building tower crane

A technology for extruding molds and trolley wires, which is applied in the field of extrusion molds for PVC trolley line rails of building tower cranes, can solve problems such as unqualified trolley line rails, deformation and bending of trolley line grooves, and affecting use safety, etc., to achieve Improve molding quality, reduce scrap rate, improve simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

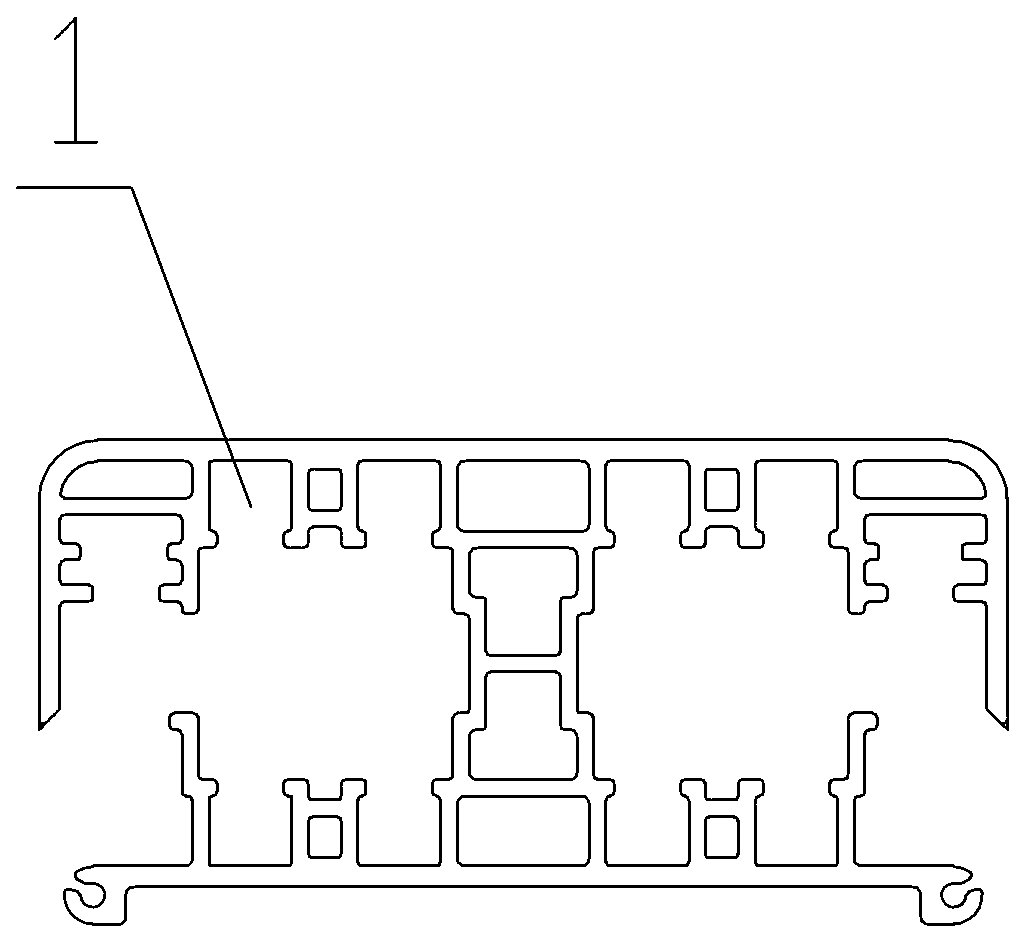

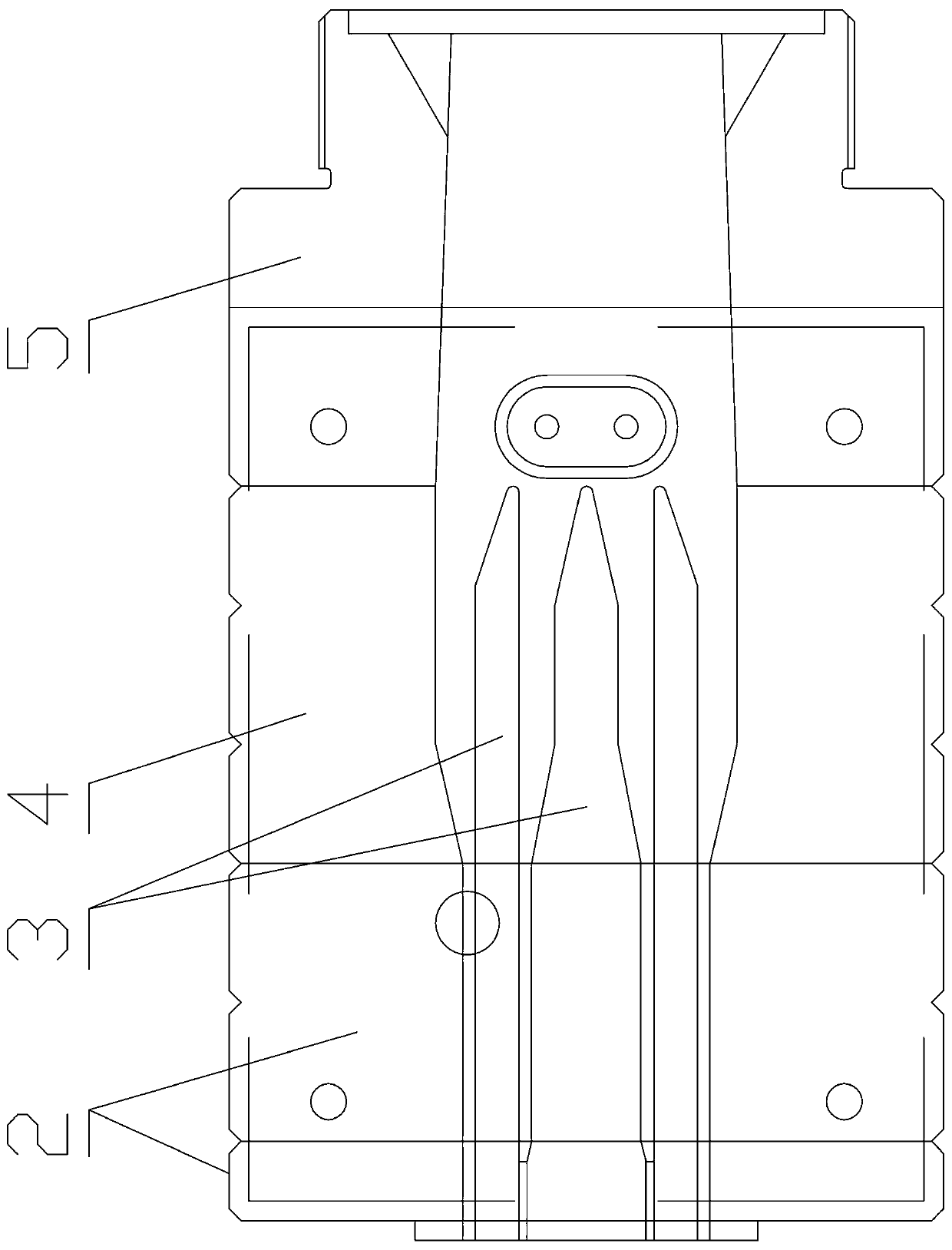

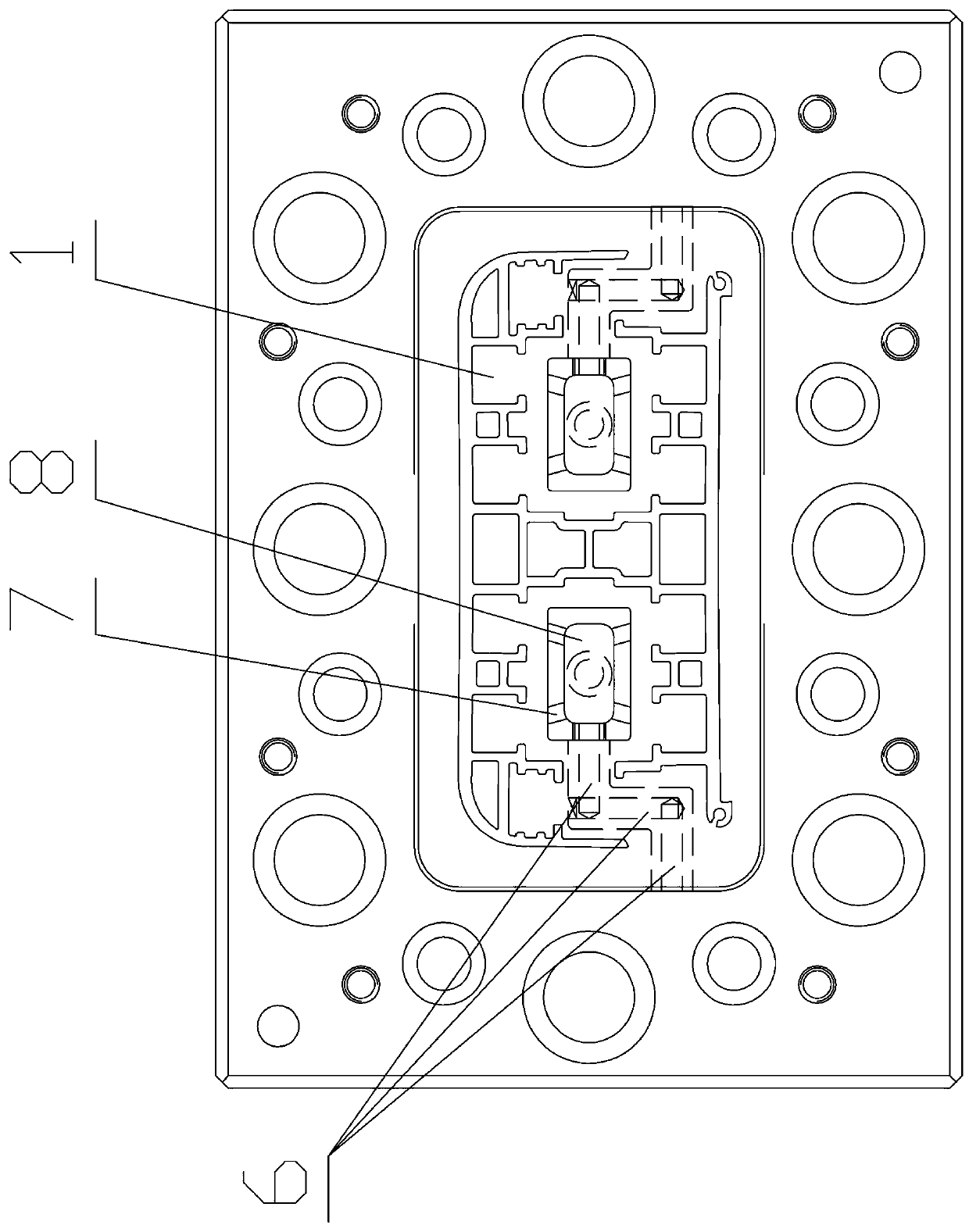

[0011] see Figure 1-Figure 3 , the present invention is a PVC trolley line track extrusion die for building tower cranes, including a die 2, a support plate 4, a mold body 5 and a mandrel 3, the cavity in the die and the profile of the PVC trolley line track The cross-section structure of the PVC trolley line track profile includes two symmetrically arranged profile cavities, and there are two cavity positions corresponding to the PVC trolley line track profile cavity at the outlet of the die. Set of special-shaped flushing devices, each set of special-shaped flushing devices includes a flushing chamber 8 arranged in the mandrel at the outlet of the die, and a water inlet pipe 6 is connected to the side of the flushing chamber outward. Lead out from the gap of the profile cavity of the PVC trolley line track to avoid interference; each cavity wall of each flushing water cavity is provided with a water spray port 7 facing each inner cavity of the profile cavity of the PVC trol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com