Test device for testing airtightness of high-pressure ball valve and test and calibration method thereof

A technology for air tightness testing and high-pressure ball valves, which is applied in fluid tightness testing, measuring devices, liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problems of low testing efficiency, low precision of manual testing, and no guarantee of safety. and other problems, to achieve the effect of preventing high-pressure test gas ejection, easy maintenance and improvement, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with drawings and embodiments.

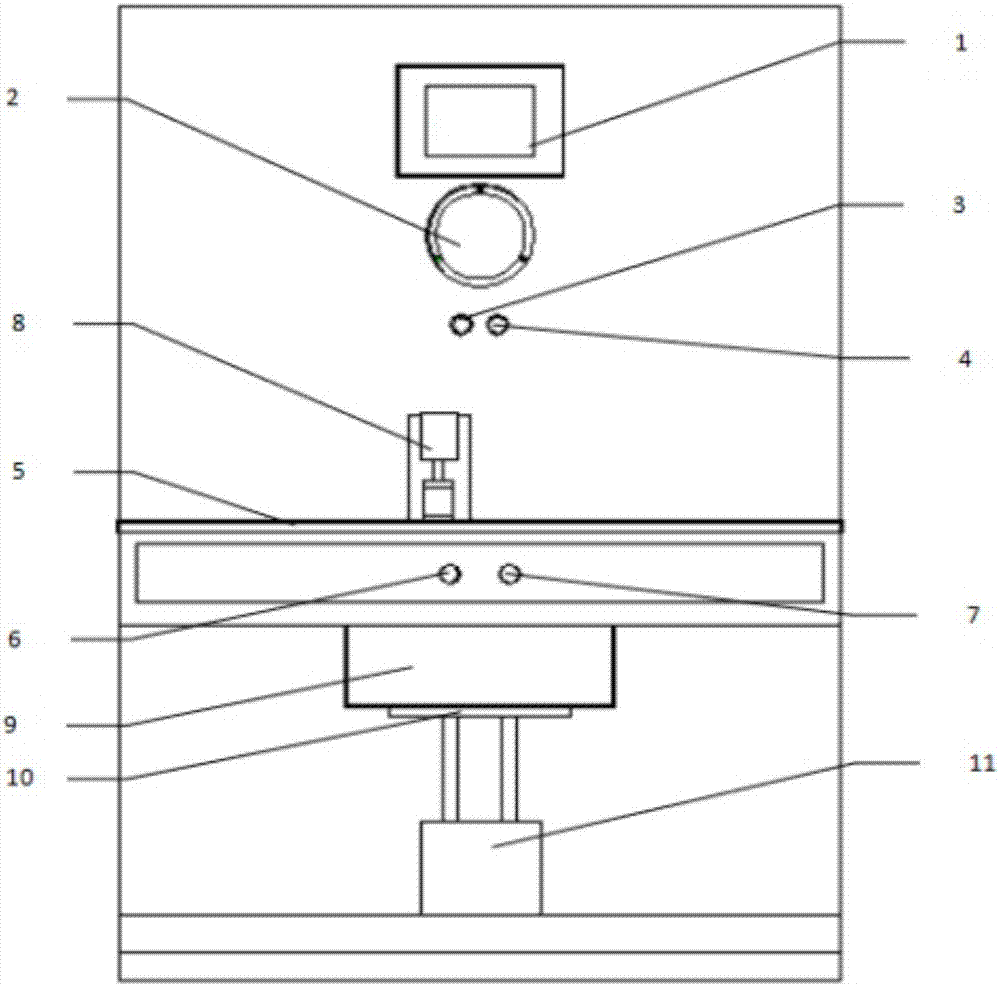

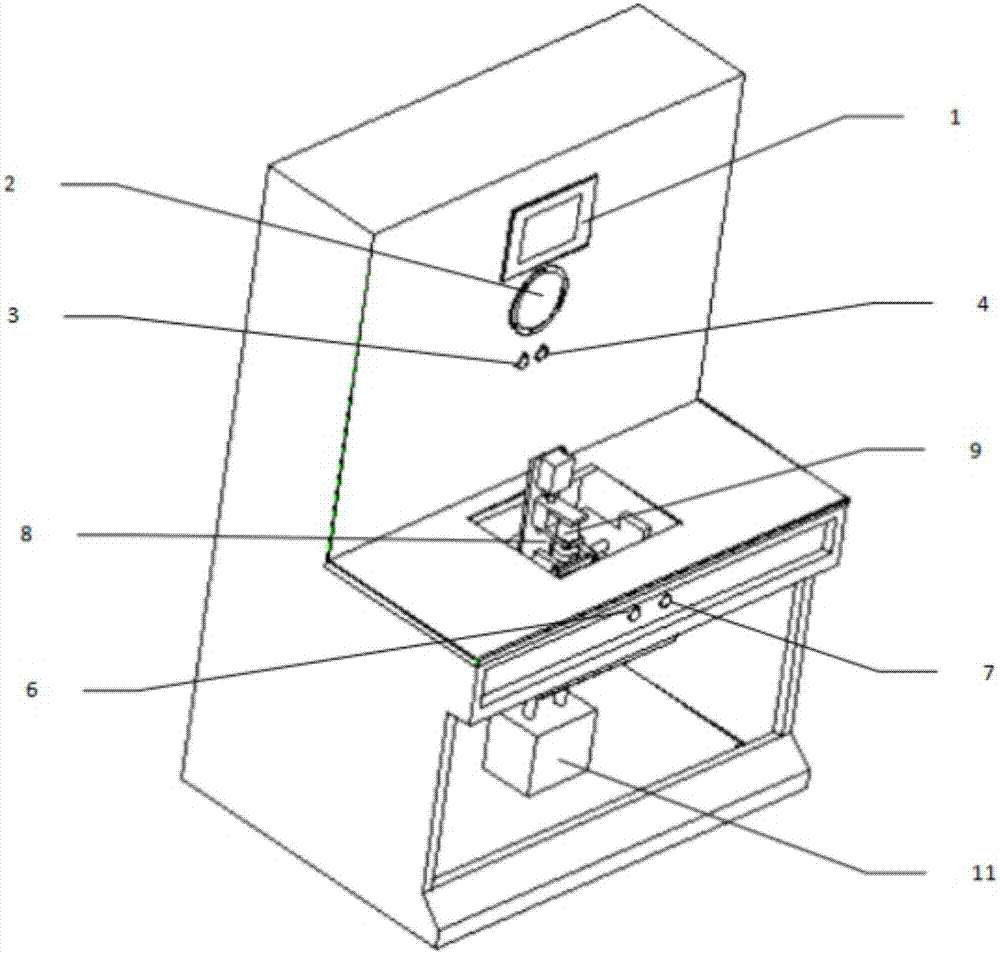

[0042] Such as figure 1 with figure 2 As shown, the device in the specific implementation of the present invention includes a worktable 5 and a test tool 8, the test tool 8 is installed and fixed at the center of the upper surface of the workbench 5, and the test tool 8 is used for testing the ball valve 20 to be tested;

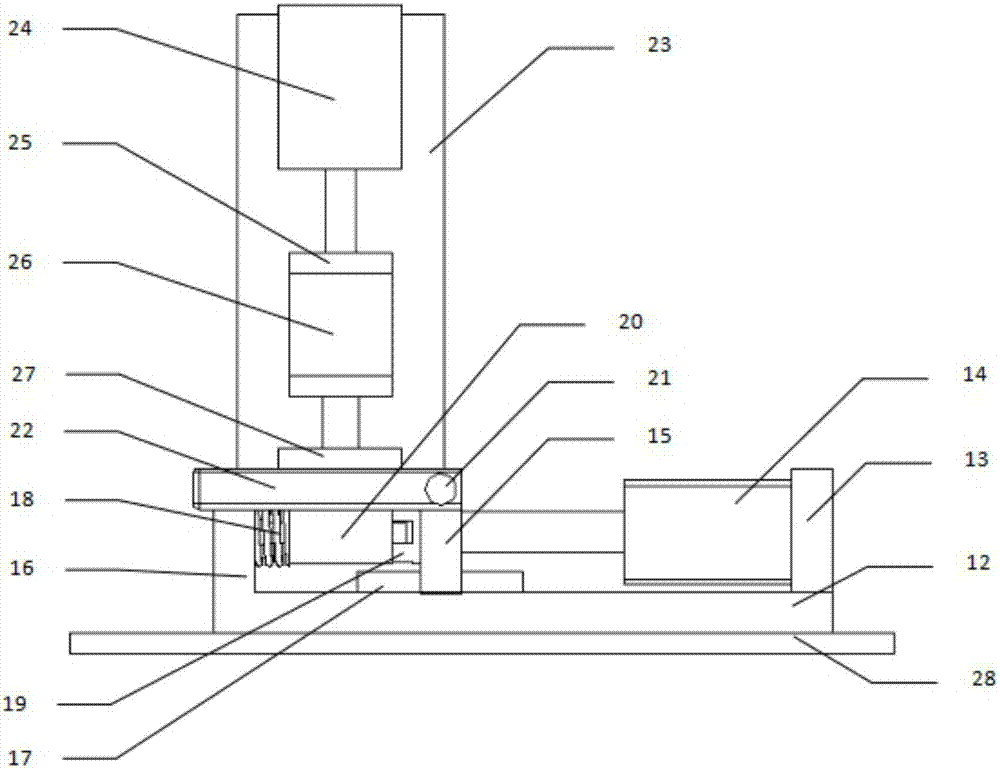

[0043] Such as Figure 3-6As shown, the test tooling 8 includes a workbench mounting plate 28, a tooling bottom plate 12, a clamping cylinder fixing plate 13, a clamping cylinder 14, an air outlet clamping block 15, an air intake clamping block 16, a clamping block slide rail 17, and an air intake clamping block Spring 18, rotating bolt 21, safety bar 22, valve opening cylinder fixed plate 23, valve opening cylinder 24, valve opening motor fixing bracket 25, valve opening motor 26 and ball valve handle rotary tooling 27; test tooling 8 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com