Wind heating device based on magnetorheological effect and heating method thereof

A magneto-rheological effect and magneto-rheological technology, applied in the direction of wind power generator, wind power motor combination, internal friction of fluid flow or friction between fluid and moving body, etc. It is difficult to further improve the heat rate, etc., to achieve the effects of easy heating efficiency and heating rate, over-speed protection, and easy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

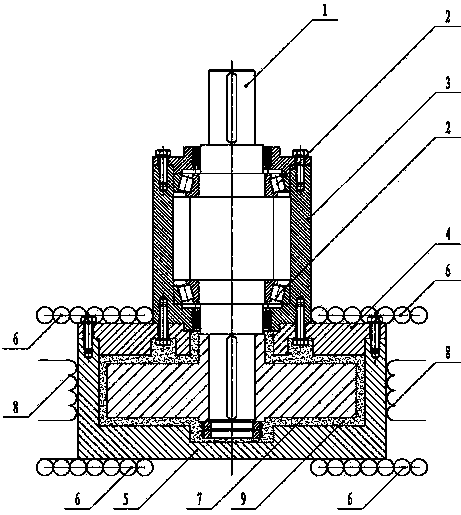

[0031] The wind heating device based on the magneto-rheological effect is as figure 1 As shown, in this structure, the end face of the heating rotor 7 is the main heating surface, and the specific scheme is as follows: the mechanical energy converted from wind energy acts on the transmission shaft 1, and the transmission shaft 1 drives the heating rotor 7 in the magneto-rheological intelligent The material 9 rotates, the electromagnetic coil 8 is installed on the end faces of the heating barrel cover 4 and the heating barrel body 5, and a weak current is passed into the electromagnetic coil 8, and a weak external magnetic field is generated near the electromagnetic coil 8, which is affected by the external magnetic field. , the yield stress of the magnetorheological smart material 9 will increase proportionally according to the strength of the excitation current, and the rotating heating rotor 7 will be hindered more, thereby generating more heat and realizing the conversion fr...

Embodiment 2

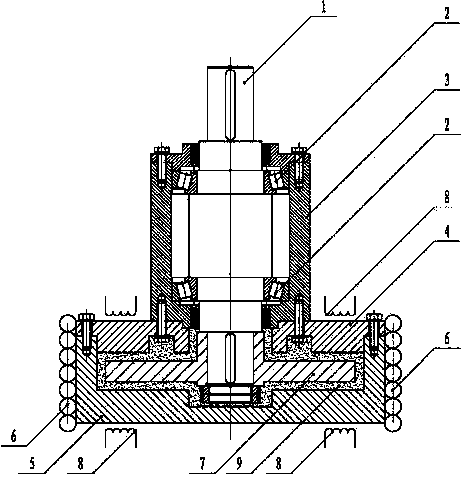

[0033] The wind heating device based on the magneto-rheological effect is as figure 2 As shown, in this structure, the cylindrical surface of the heating rotor 7 is the main heating surface, and the specific scheme is as follows: the mechanical energy converted from wind energy acts on the transmission shaft 1, and the transmission shaft 1 drives the heating rotor 7 in the magneto-rheological The intelligent material 9 rotates, the electromagnetic coil 8 is installed on the cylindrical surface of the heating barrel body 5, and a weak current is passed into the electromagnetic coil 8, and a weak external magnetic field is generated near the electromagnetic coil 8. The yield stress of the variable smart material 9 will increase proportionally according to the strength of the exciting current, and the rotating heating rotor 7 will be hindered more, thereby generating more heat, realizing the conversion from mechanical energy to thermal energy, and heat exchange The component 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com