Processing method of 3D printing sharp tracks

A 3D printing and processing method technology, applied in the field of 3D printing, can solve the problems affecting the product quality of 3D printing components, material accumulation at corners, etc., and achieve the effect of avoiding material accumulation at corners and improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

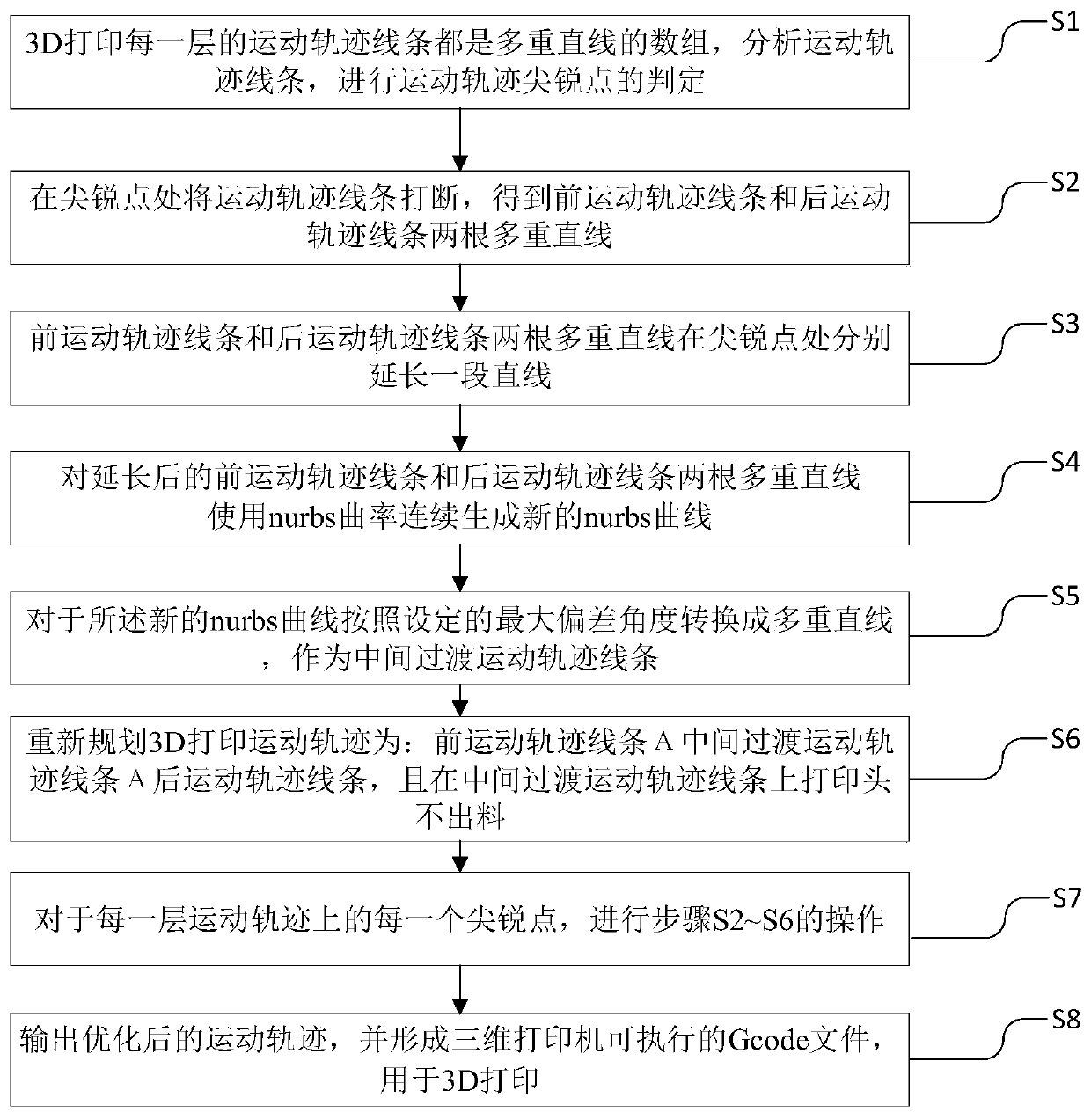

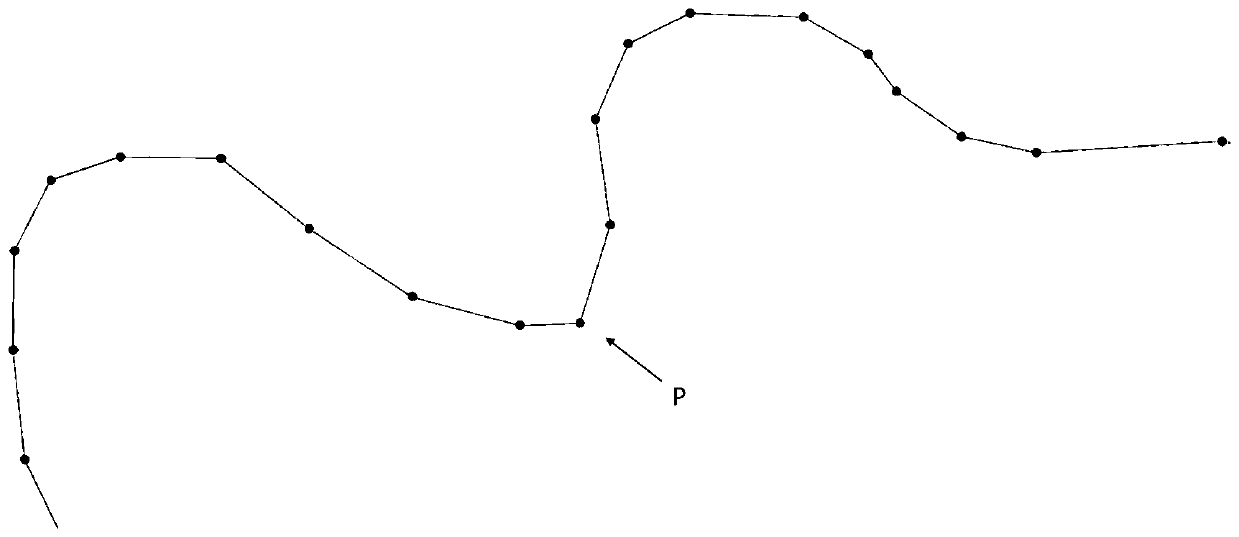

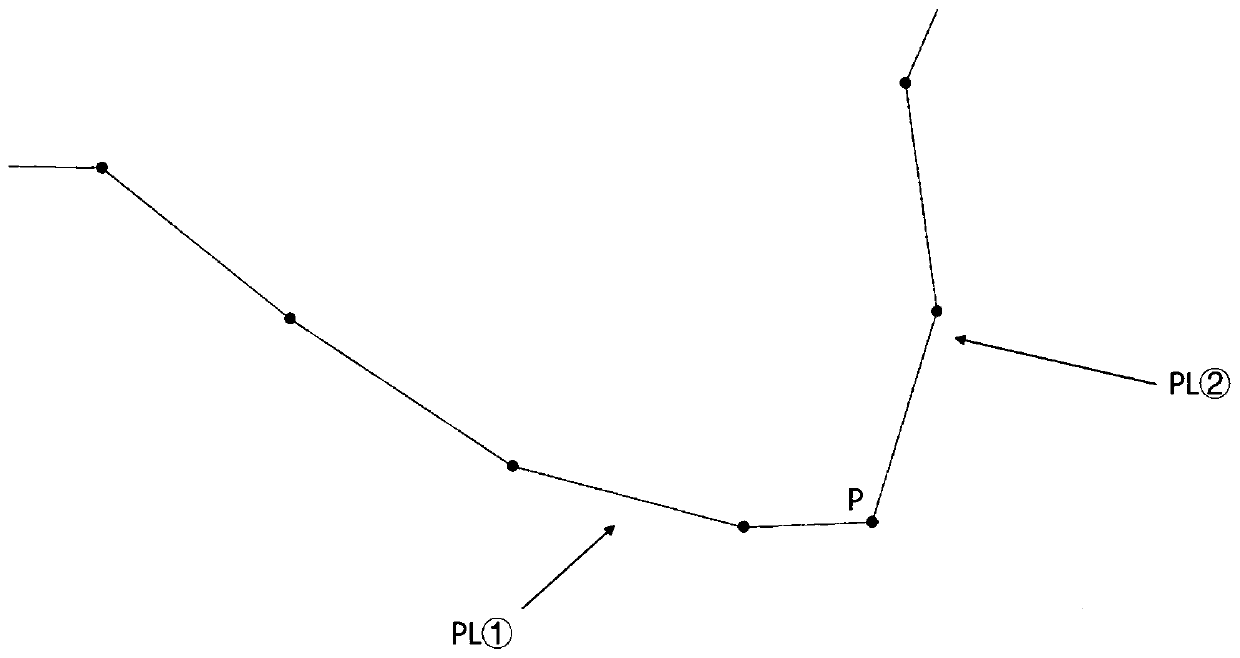

[0039] The embodiment of the present application provides a processing method for 3D printing sharp trajectories, which solves the problem of running track programs with sharp points for large machine tools in the prior art, and the movement device will decelerate and vibrate at the sharp points of the running track. This further affects the fused deposition process of 3D printing, leading to material accumulation at corners, and ultimately affecting the product quality of 3D printing components. By optimizing the printing movement path, the deceleration and vibration of the moving device during the actual movement are reduced, avoiding Corner accumulation phenomenon effectively improves the printing quality of 3D printing components.

[0040] The technical solution in the embodiment of the present application is to solve the above-mentioned crosstalk problem, and the general idea is as follows:

[0041] Before printing on a large FDM machine tool, it is necessary to slice the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com