Road greening flowerpot placement structure and construction method thereof

A flowerpot and road technology, which is applied in the filling of flowerpots, botanical equipment and methods, goods transport vehicles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

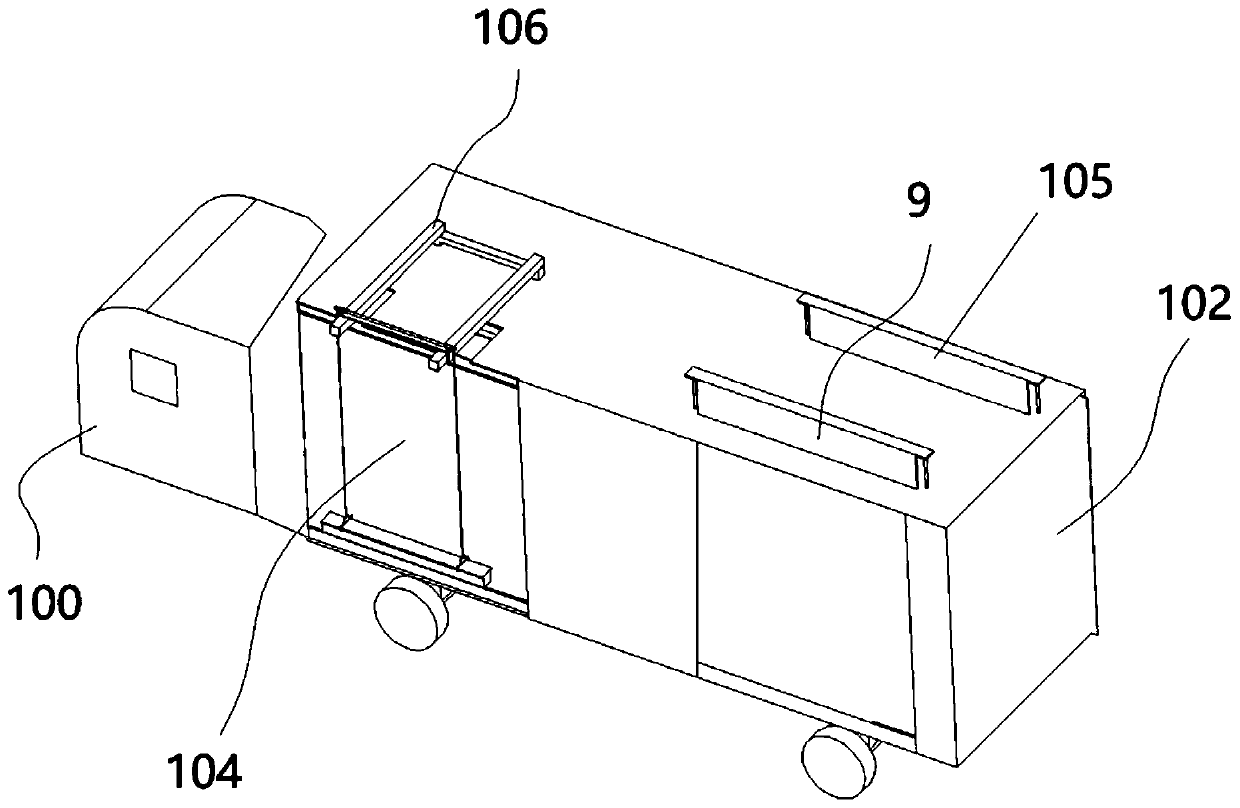

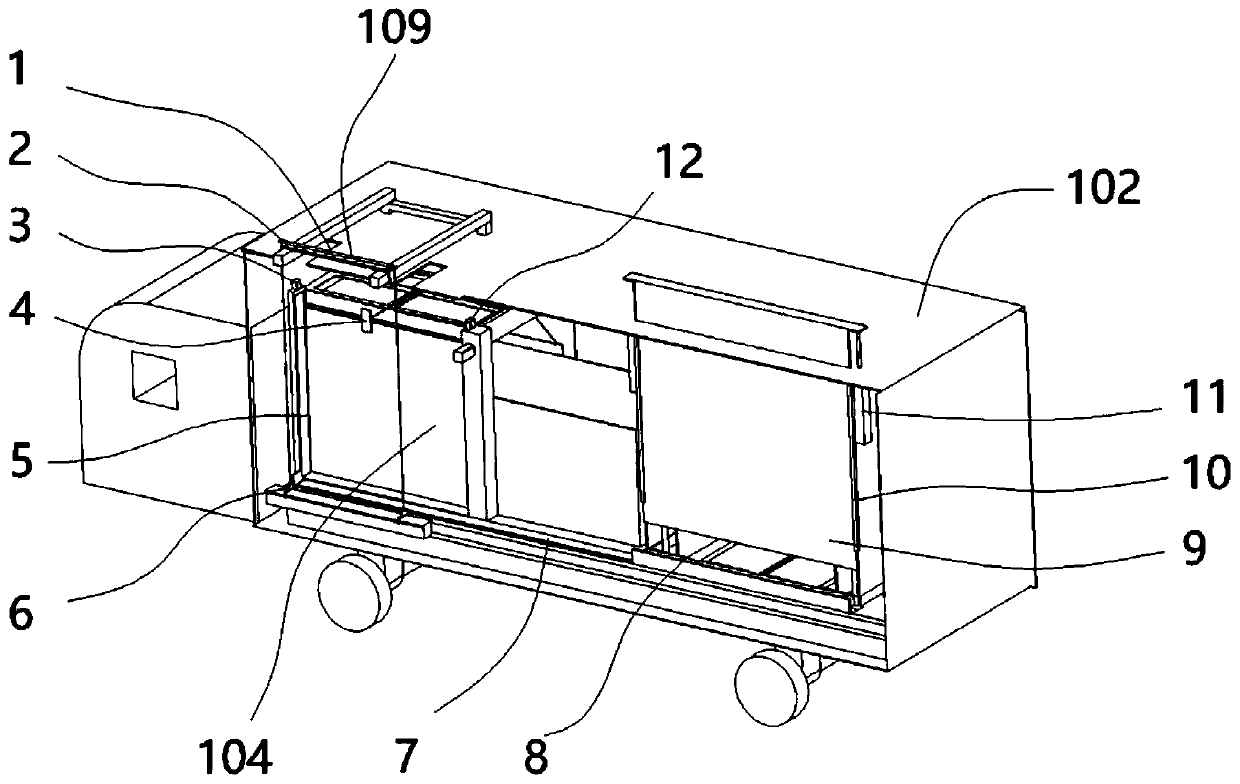

[0038] As shown in the figure, the road greening flowerpot recovery structure includes an engineering vehicle 100, and the engineering vehicle 100 is provided with a through base plate 101, and a compartment 102 is installed on the base plate 101; Material opening 104;

[0039] A first gear 122 is connected to the bottom surface of the bottom plate 101 , and the first gear 122 meshes with a second gear driven to rotate by a third motor 121 , and the third motor 121 is fixed on the chassis of the engineering vehicle 100 . In the construction process, sometimes the lane is reversed. In order to meet the needs of construction, the compartment 102 of the engineering vehicle 100 can be rotated to change the position, that is, the second gear is driven by the third motor 121 to rotate and the first gear 122 is driven. The rotation makes the bottom plate 101 rotate to drive the compartment 102 to rotate 180 degrees or 360 degrees as a whole to adjust the position to meet the requirem...

Embodiment 2

[0055] In the actual construction process, sometimes it is not simply the recycling of old flower pots, but also the placement of flower pots. Therefore, this example proposes a structure and method for fast cutting and saving manpower for flower pots. ,details as follows:

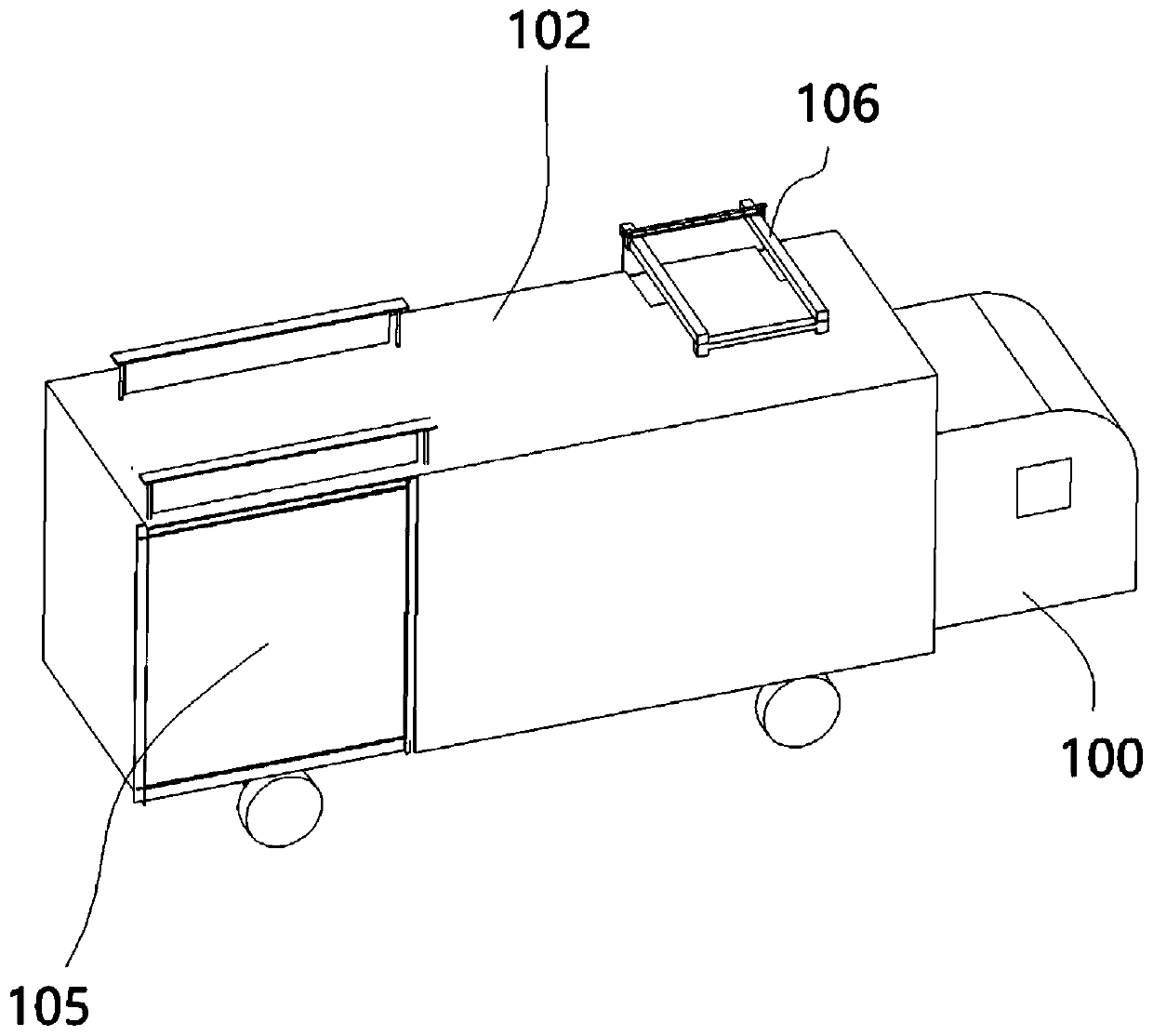

[0056] As shown in the figure: the road greening flowerpot placement structure includes an engineering vehicle 100, and the engineering vehicle 100 is provided with a through base plate 101, and a compartment 102 is installed on the base plate 101; in this example, the base plate 101 can also pass through the third Motor 121 drives the rotation adjustment position, and its structure and principle are identical with embodiment 1.

[0057] A side front of the compartment 102 is provided with an inlet and outlet opening 104, and the rear of the compartment 102 both sides is respectively provided with a feed gate 105 and a discharge gate 9, and the discharge side both sides of the flowerpot placement box 200 a...

Embodiment 3

[0073] In greening construction, sometimes it is necessary to recycle old flower pots and place new flower pots. Therefore, in this embodiment, by combining implementation 1 and implementation 2, the rapidity of changing flower pots can be realized.

[0074] As shown in the figure: the road greening flowerpot replacement structure includes an engineering vehicle 100, and the engineering vehicle 100 is provided with a through base plate 101, and a compartment 102 is installed on the base plate 101; in this example, the base plate 101 can also pass through the third Motor 121 drives the rotation adjustment position, and its structure and principle are identical with embodiment 1.

[0075] One side front of the carriage 102 is provided with an inlet and outlet opening 104, and the rear of both sides of the carriage 102 is respectively provided with a feed door 105 and a discharge door 9.

[0076] The top of the front section of the compartment 102 is provided with a hanger 106, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com