Belt as a continuous traction mechanism and method for making the same

A technology of traction mechanism and belt, applied in the direction of belt fasteners, chemical instruments and methods, belt/chain/gear, etc., can solve the problems of cumbersome structure, interference, etc., and achieve high durability, restrain bending, and long-lasting stability running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

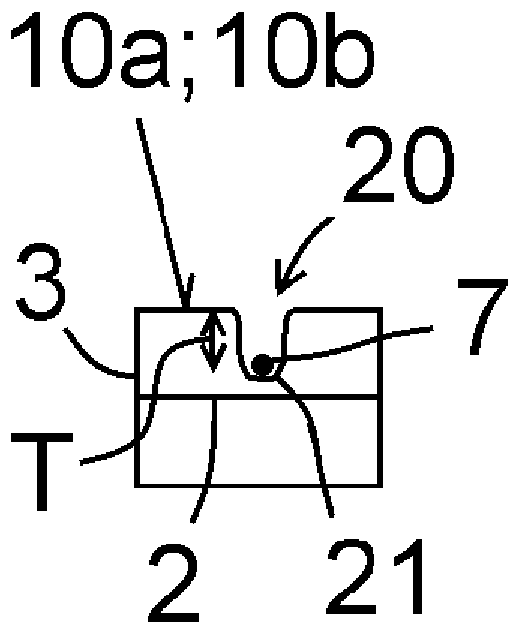

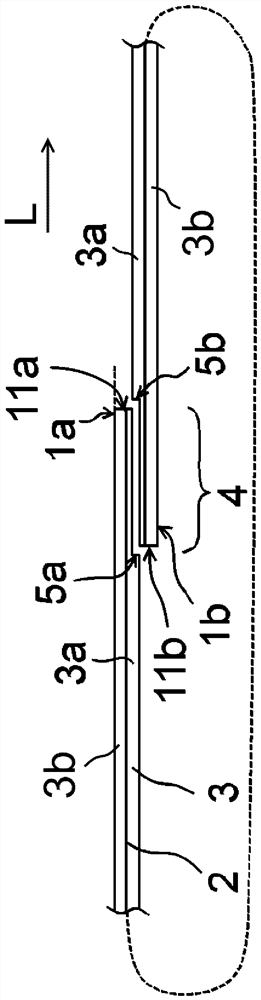

[0039] figure 1 The belt 1 shown in can be used as a traction mechanism, especially for agricultural machine conveyor belts, especially in the bale forming mechanism of a baler, and in this case in the baler in multiple steering wheels and drives. Continuous on wheels (not shown). However, the belt 1 can also be used in other fields, and in this case has a configuration different from that shown, as will be seen from the following description.

[0040] For this purpose, the belt 1 is joined in its end regions 1a, 1b so as to form a continuous belt 1 which can be tensioned, for example, on the rollers of a conveying mechanism of an agricultural machine. The belt 1 consists at least in places of a fabric-layer-reinforced, cross-linked polymer and thus has at least one reinforced fabric layer 2 which is at least partly embedded in a polymer layer 3 , in particular a rubber layer, so that the fabric layer 2 It is covered at least partially from above and below by a polymer layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com